System for determining fill level

A filling level, fuel tank technology, applied in the layout, instrumentation, liquid/fluid solid measurement, etc. combined with the fuel supply of the internal combustion engine, can solve the problems of failure, cost, etc., and achieve the effect of low cost and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

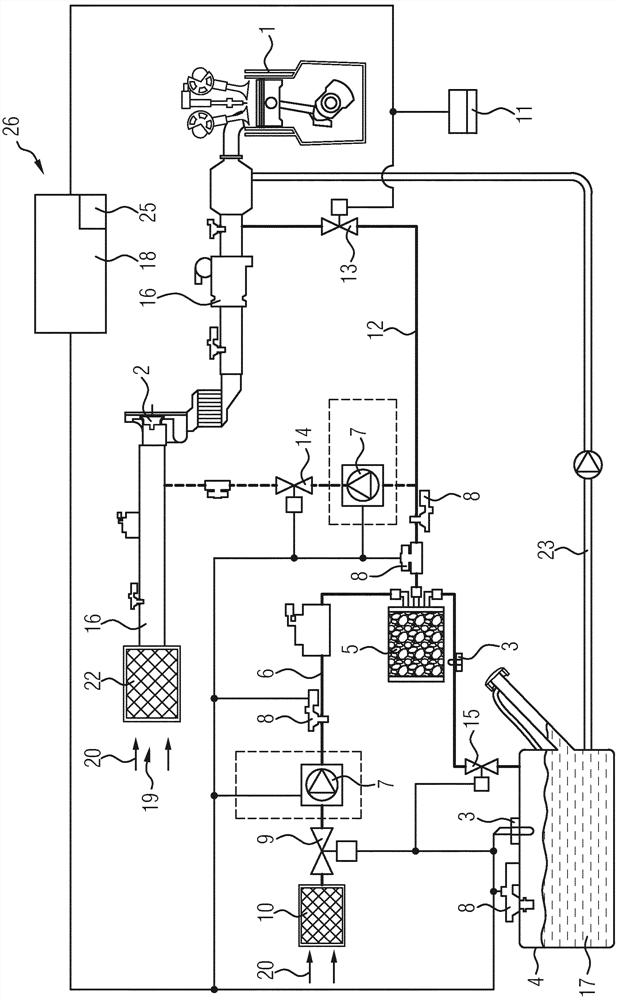

[0015]figure 1 An internal combustion engine 1 is shown. The internal combustion engine 1 is supplied to fresh air 20 via the intake line 16. The fresh air 20 is guided from the fresh air side 19 through the air filter 22 to the intake line 16, and may be compressed by means of exhaust turbocharger 2 or supercharger, and then supplied to internal combustion engine 1 Combustion chamber. Further, the internal combustion engine 1 is supplied with fuel 17 from the fuel tank 4 via the fuel line 23.figure 1 Furthermore, a fuel tank system 26 having a fuel tank 4 and a battery element 5 for temporarily storeing a hydrocarbon is exhibited. The fuel tank 4 and the battery element 5 are connected to each other such that the hydrocarbon from the fuel 17 located in the fuel tank 4 can be stored in the battery element 5. The battery element 5 can, for example, be formed as an active carbon storage battery. The activated carbon battery is a kanister, wherein carbon is arranged such that the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com