Spring brackets for coil springs

A technology of spring brackets and coil springs, applied in the direction of springs, vehicle springs, elastic suspensions, etc., can solve the problem that damping elements do not have advantageously bent collars, etc., to prevent premature local damage, improve ride comfort, The effect of simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

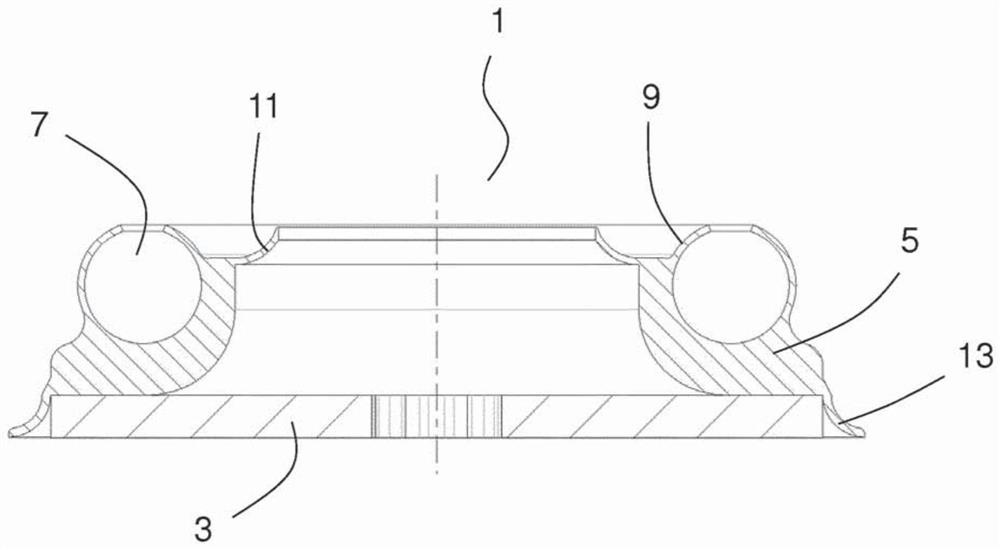

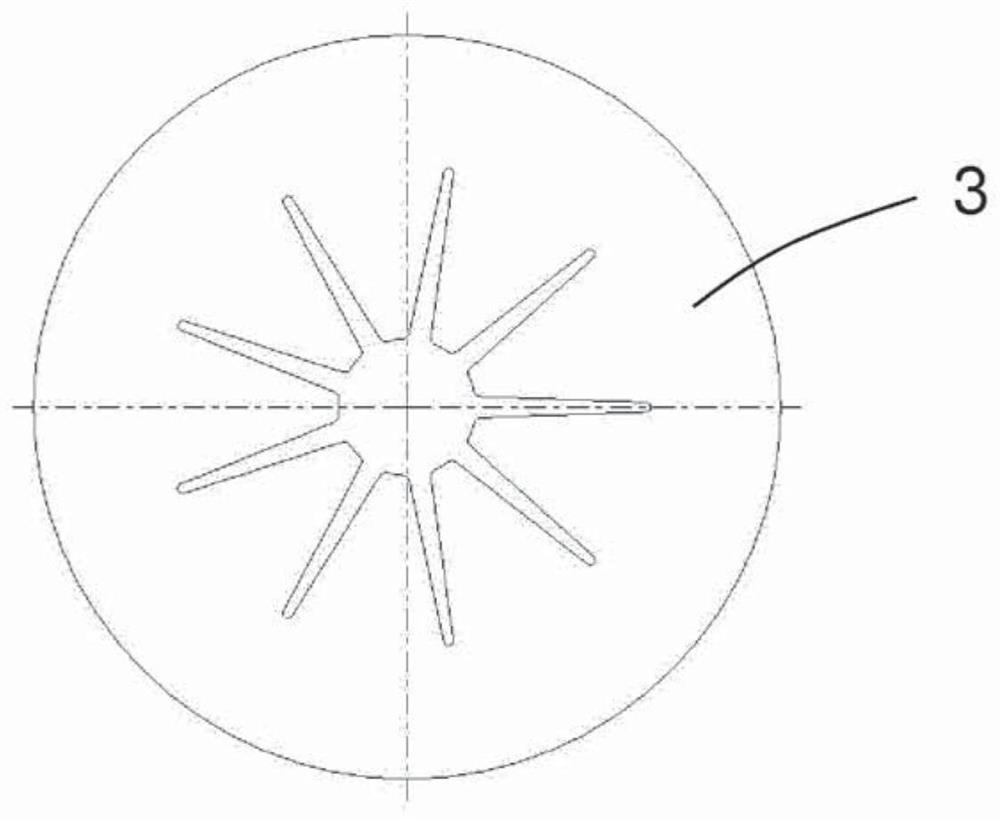

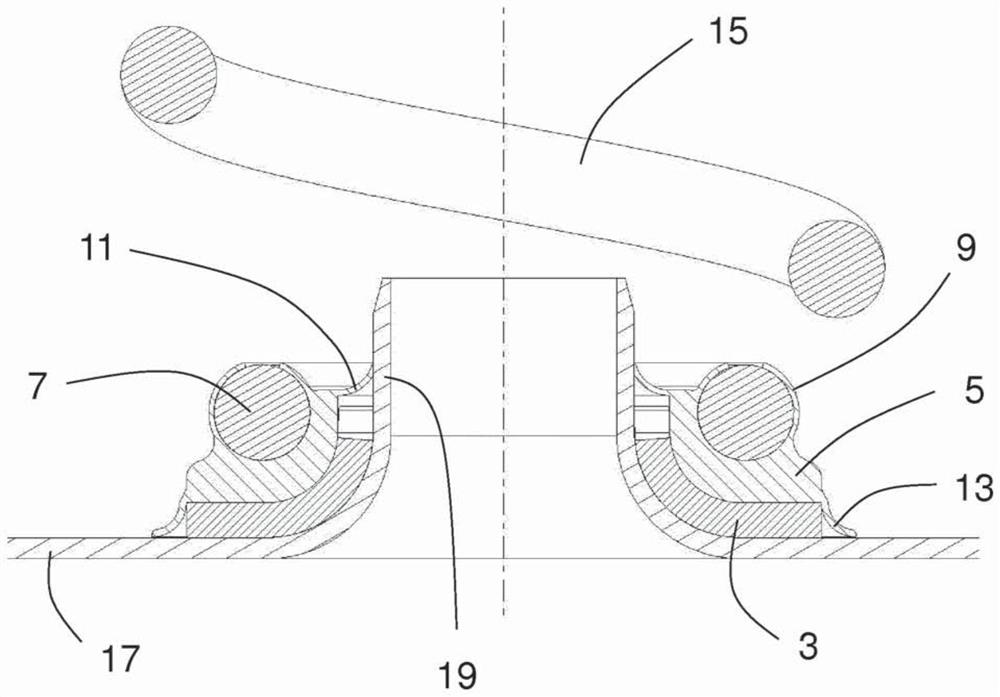

[0034] exist figure 1 An embodiment of a spring carrier 1 according to the invention is shown in longitudinal section. In this embodiment, the component is configured to be rotationally symmetrical about an axis shown in dotted lines. The spring carrier 1 comprises a thermoplastic-based annular receiving element 5 . In one embodiment, based on thermoplastic polyurethane (trade name Depend on BASF Polyurethanes GmbH) material is added, while in another embodiment a polyethylene-based material is added. The receiving element 5 has a top side and a bottom side. A top side is provided for receiving one end of the coil spring. In this embodiment, the area 7 provided for receiving the spring is configured as an annular cavity formed by the clamping element 9 . The clamping element 9 is integrally connected to the body of the element 5 and has a gap at the top end of the clamping element 9 through which the helical spring can be pressed into the cavity 7 .

[0035] The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com