Rotary damper

A rotary damper and damper technology, applied in non-rotational vibration suppression, shock absorber, shock absorber, etc., can solve the problems of unsuitable multi-functional rotary damper and the inability to realize economical realization of high-pressure end side seals of gears, etc. achieve simple structure and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

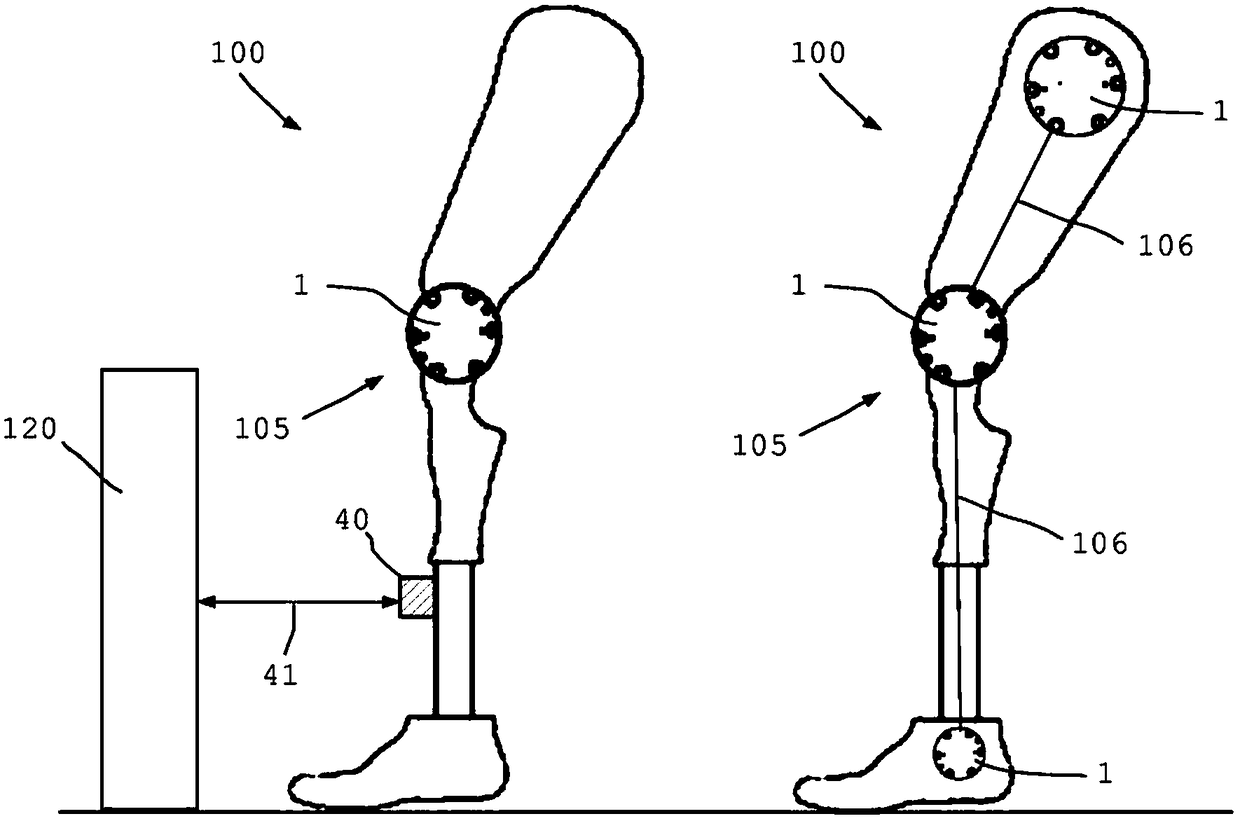

[0124] figure 1 The use of the rotary damper 1 according to the invention as device 100 on a prosthesis 105 is shown. The prosthesis 105 shown in the left half depicts use on the knee joint where the rotational damper 1 dampens the rotational movement between the thigh and the calf.

[0125] The rotary damper 1 can also be controlled by means of sensor data from a sensor device 40 which, for example, detects a distance 41 to an object 120 . For example, if during a climbing step the distance and height of successive steps are detected by such a sensor device 40 , the rotary damper 1 can be targeted with the following requirements.

[0126] figure 1 The right half of FIG. 1 shows a leg prosthesis as prosthesis 105 , wherein three rotational dampers 1 are provided here, namely one at the ankle, one at the knee and one at the hip joint. The three rotary dampers 1 are connected together via one or more fluid and control lines 106 such that hydraulic interaction between the indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com