Infrared sensor device

An infrared sensor, infrared technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of increased heat capacity, volume, and heat capacity of light guides, and achieve high measurement directivity, reduced heat capacity, and high thermal response. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

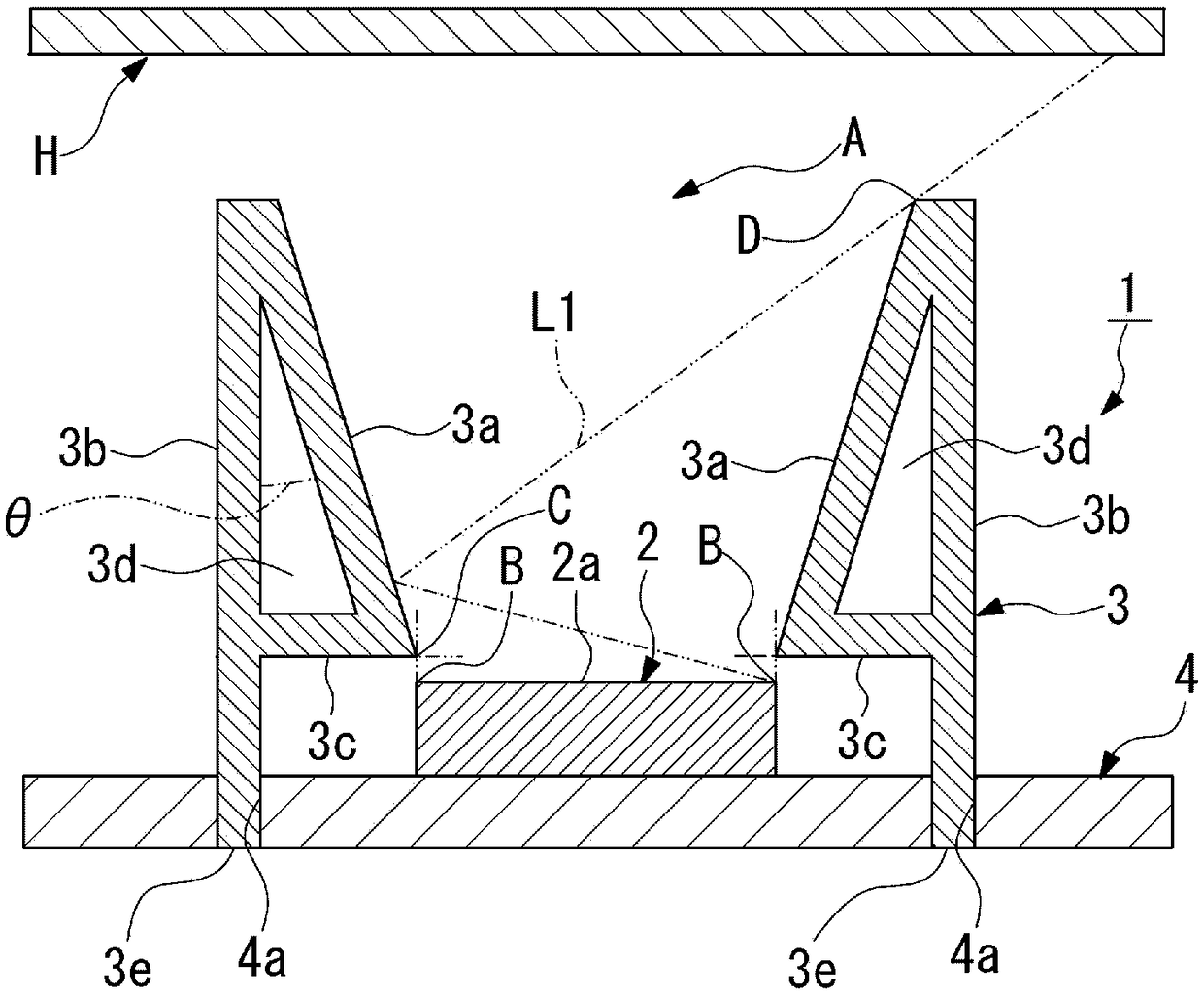

[0037] Below, refer to Figure 1 to Figure 4 A first embodiment of the infrared sensor device according to the present invention will be described.

[0038] Such as figure 1 As shown, the infrared sensor device 1 of the present embodiment measures, for example, the temperature of a fixing roller of toner, and a measuring object H such as a fixing roller is provided toward the opening A.

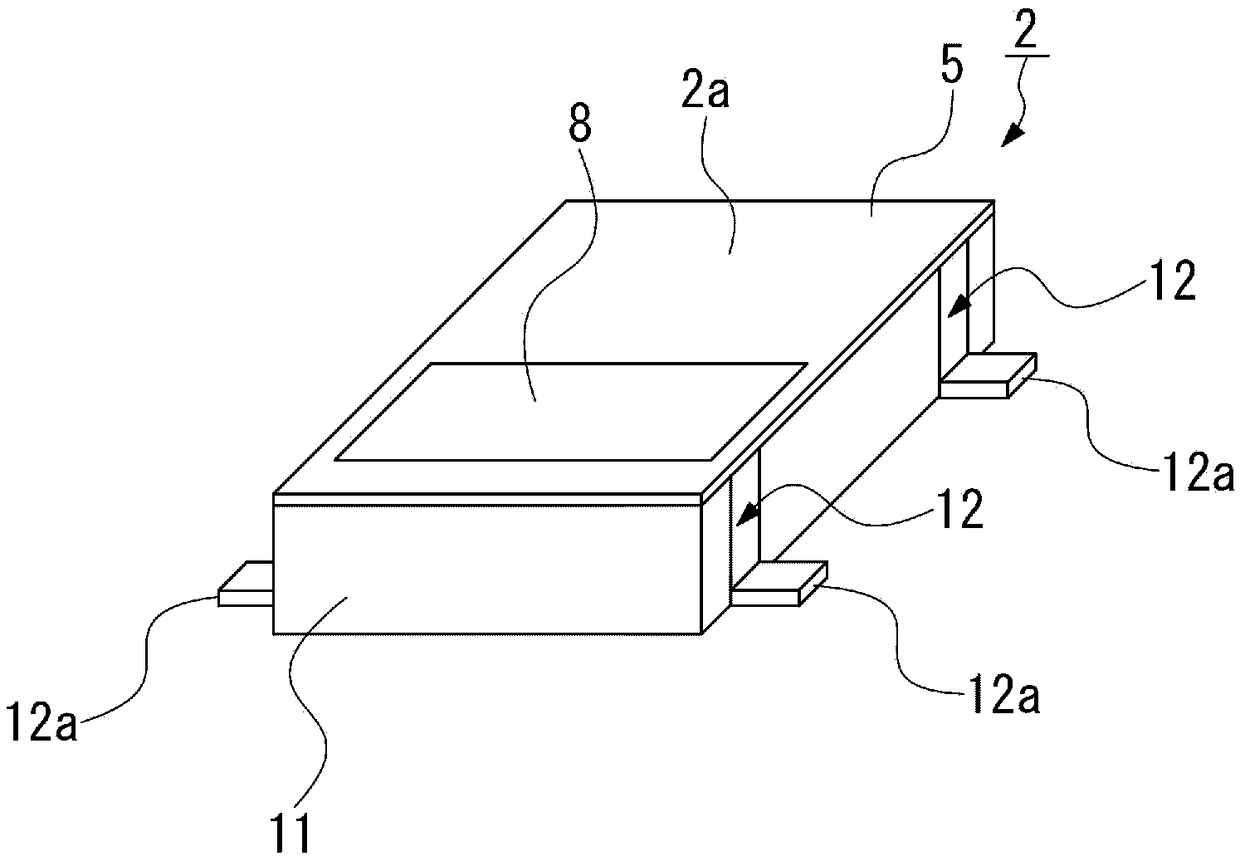

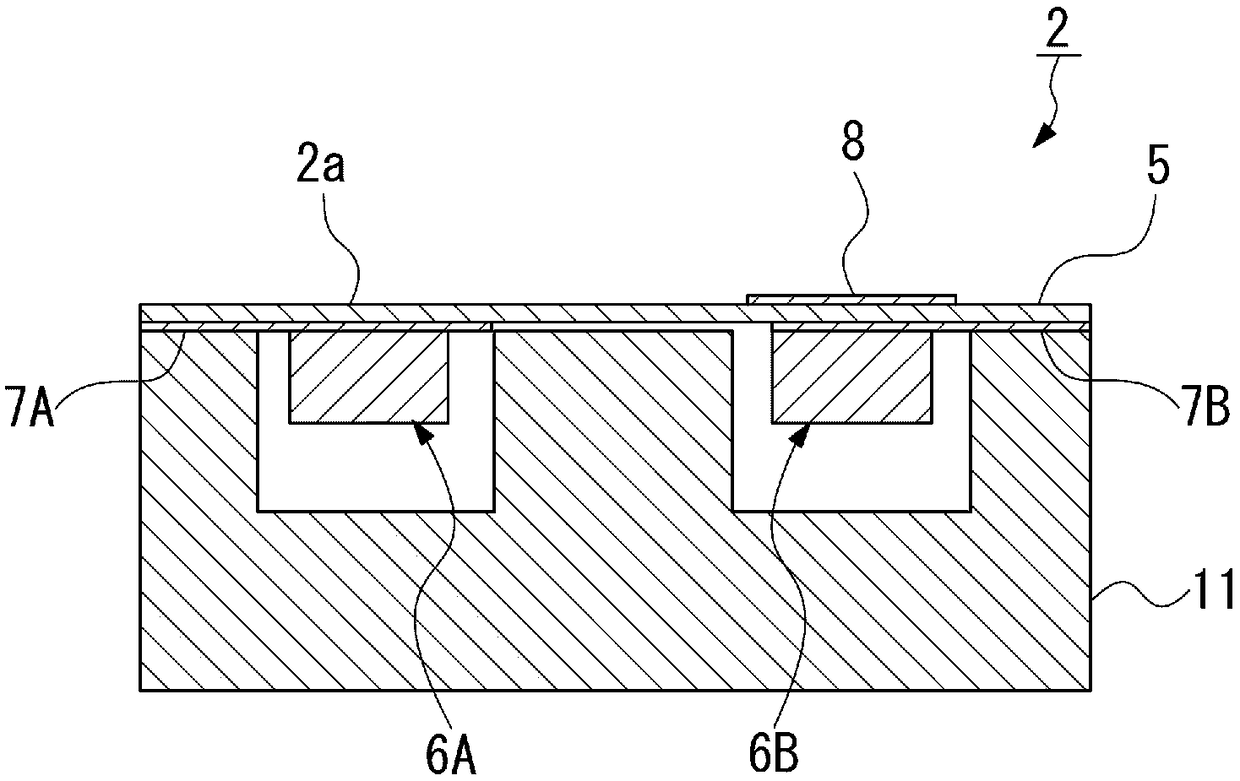

[0039] This infrared sensor device 1 is provided with an infrared sensor main body 2, a cylindrical light guide member 3 provided around at least the light receiving surface 2a of the infrared sensor main body 2 and having an opening A directly above the light receiving surface 2a, and an infrared sensor main body provided with 2 and the substrate 4 of the light guide path component 3. In addition, in figure 1 In , the infrared sensor main body 2 is schematically shown.

[0040]The light guide member 3 is formed of a plate, and at least one of the surfaces surrounding the light receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com