Staggered rotational measuring and positioning device

A technology of positioning device and rotation measurement, which is applied in the direction of positioning device, measuring/indicating equipment, clamping, etc., can solve the problems affecting the accuracy of the rope groove and prone to positioning deviation, so as to solve the problem of easy deviation, avoid measurement deviation and ensure Precise and detailed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

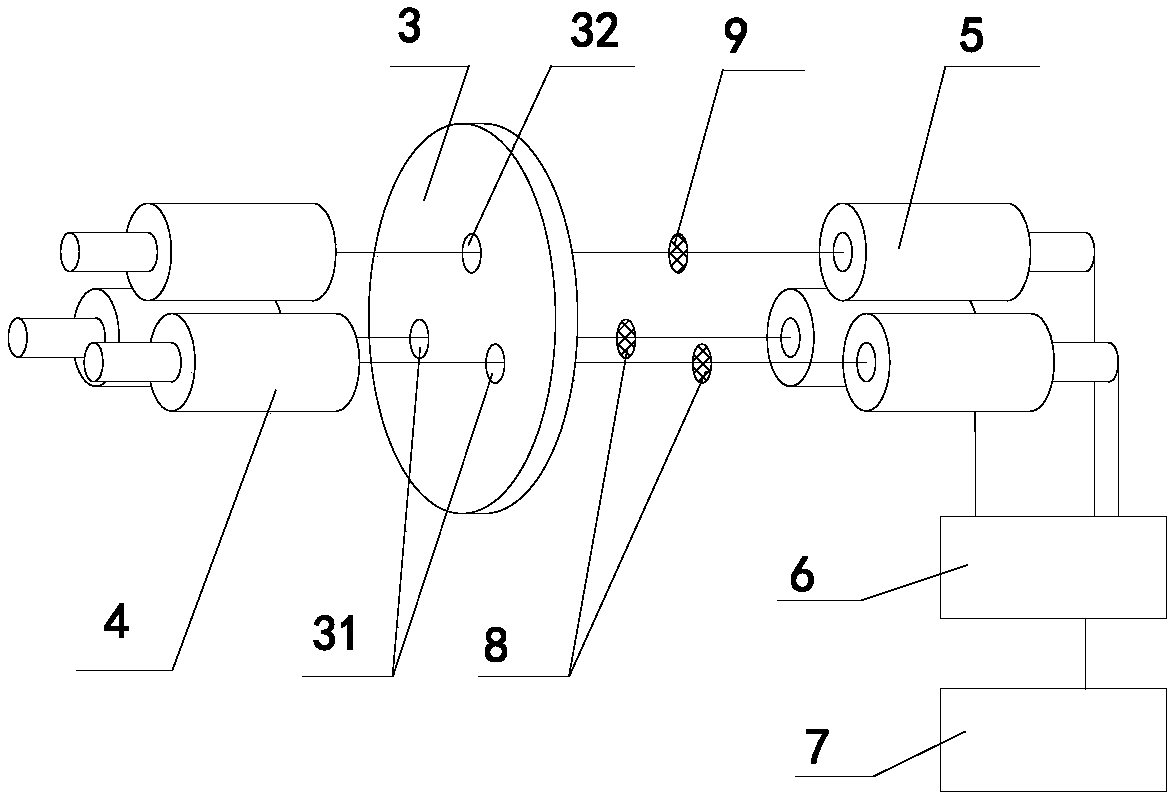

[0021] refer to figure 1 , a dislocation-type rotary measurement and positioning device proposed by the present invention includes: a scale turntable 1, a rotating shaft 2, a light beam plate 3, a light-emitting component 4, a light-sensing component, a signal acquisition module 6 and a control module 7.

[0022] The scale turntable 1 is installed on one end of the rotation shaft 2, and the scale turntable 1 coincides with the center line of the rotation shaft 2 and rotates with the rotation shaft 2. Specifically, during the machining process, the rotating shaft 2 communicates with the workpiece processing mechanism, so as to measure and monitor the rotation angle positioning of the workpiece during the machining process through the scale turntable 1 .

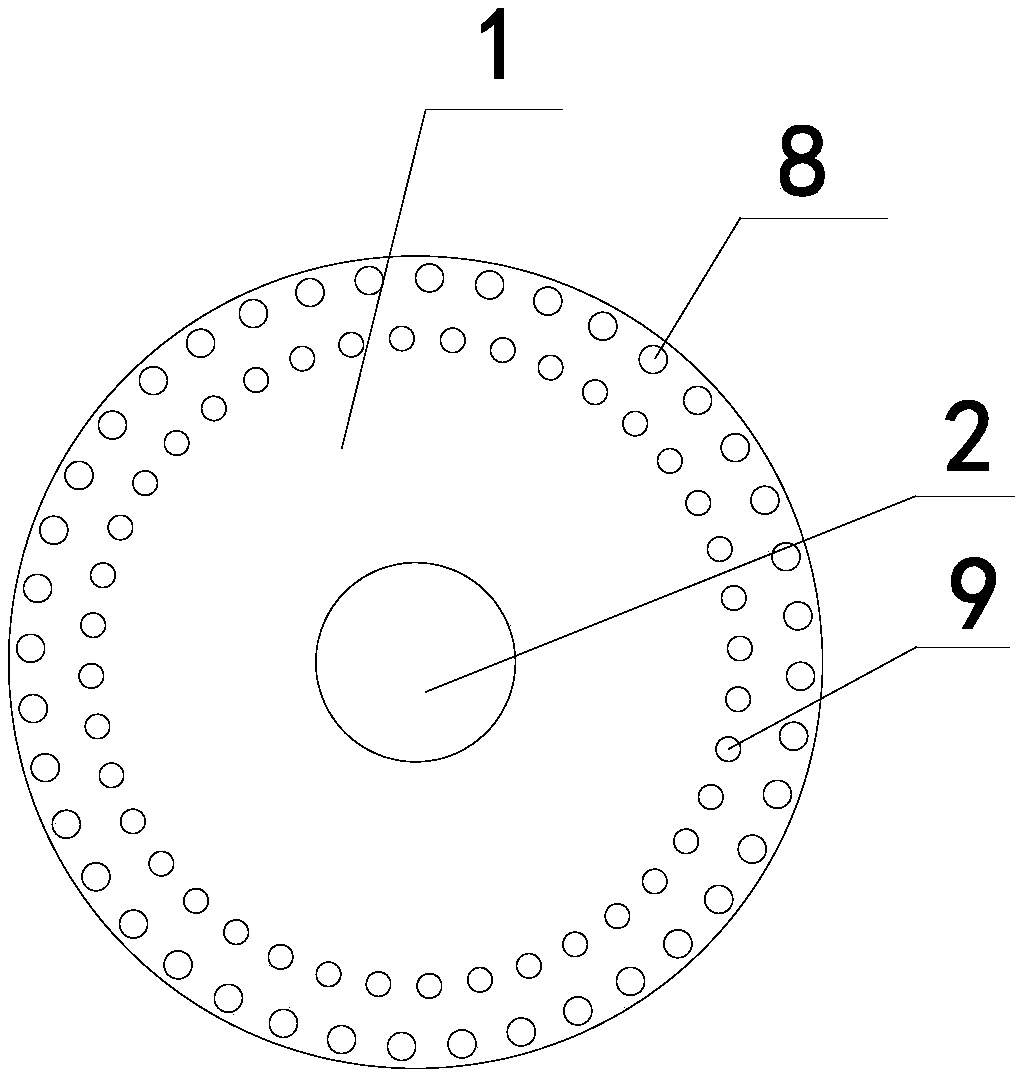

[0023] The scale dial 1 is provided with a plurality of first light-transmitting structures 8 and a plurality of second light-transmitting structures 9 , and the number of the first light-transmitting structures 8 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com