Automatic feeding and receiving apparatus of spinning machine for trial drying filter

An automatic feeding and receiving device technology, applied in the direction of conveyors, loading/unloading, conveyor objects, etc., can solve the problems of difficult to guarantee processing quality and work efficiency, low feeding accuracy, high labor intensity, etc., to achieve saving Artificial, improve production efficiency, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

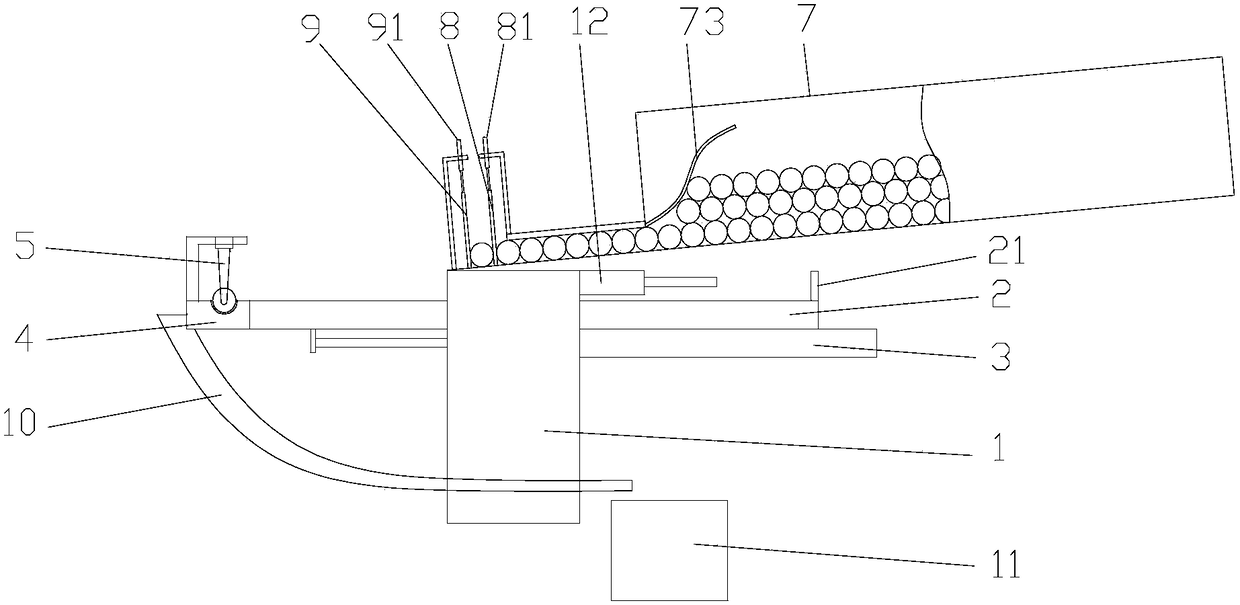

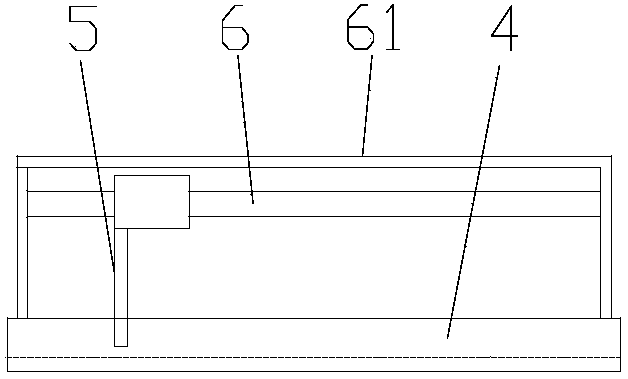

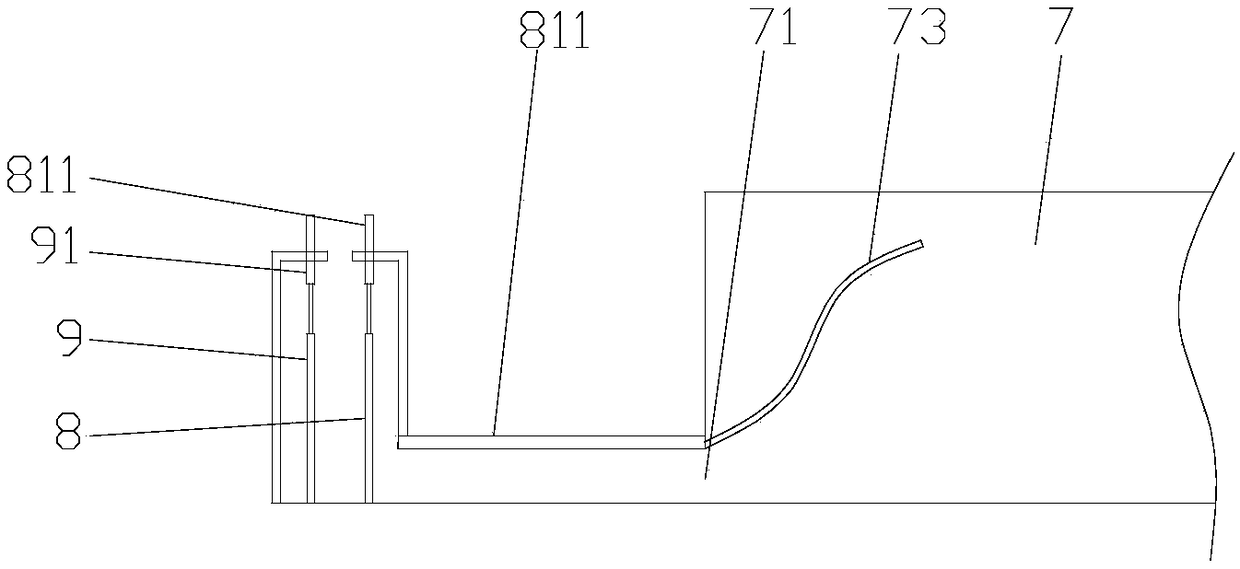

[0023] Embodiment 1: refer to figure 1 As shown, the automatic feeding and receiving device of the spinning machine for trial production of dry filters includes a feeding unit and a receiving unit on the bottom side of the feeding unit. The feeding unit includes a feeding mechanism that pushes the blank to the loading table of the spinning machine, The feeding mechanism that supplies blanks for the ejector mechanism, and the ejector mechanism that controls the ejector make a translation mechanism on the side of the spinning machine that is close to / away from the loading table of the spinning machine. The translation mechanism includes a bracket 1 arranged on the side of the spinning machine, Skateboard 2 that reciprocates linearly on the support perpendicular to the feeding direction of the spinning machine. The feeding direction of the spinning machine refers to the moving direction of the spinning wheel frame of the spinning machine, that is, the longitudinal direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com