Gas stopping brick lining of titanium tetrachloride boiling chlorination furnace and furnace building method

A technology of boiling chlorination furnace and titanium tetrachloride, applied in the direction of titanium tetrachloride, titanium halide, furnace, etc., can solve the problems of short service life of chlorination furnace and poor enterprise benefit, so as to improve the material grade and prolong the use. Longevity and the effect of increasing business efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

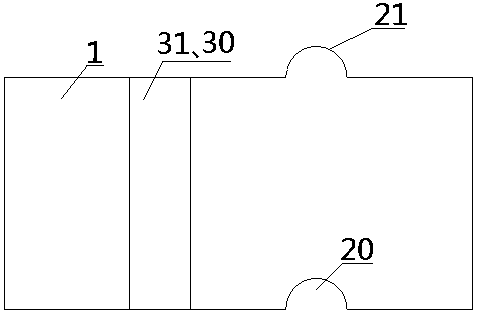

[0023] Embodiment one, such as figure 1Shown, the titanium tetrachloride fluidized chlorination furnace gas-stop brick lining of the present invention is formed by laying bricks or stones by trapezoidal flat edge brick 1, and the two waist rectangular opposite faces in the six outer sides of long trapezoidal flat edge brick 1 and two Each group of opposite faces of the upper and lower trapezoidal opposite sides of the waist rectangle is made of a contact surface perpendicular to the long axis of the long trapezoidal flat side brick and corresponding to the convex edge of the groove, and the groove of the adjacent brick during masonry The contact surface and the rib contact surface are embedded with each other. The joints between adjacent bricks are bonded with a refractory adhesive. It has the advantages of preventing chlorine gas from penetrating through the brick lining brick layer from corroding the metal shell of the furnace body, and significantly prolonging the service ...

Embodiment 2

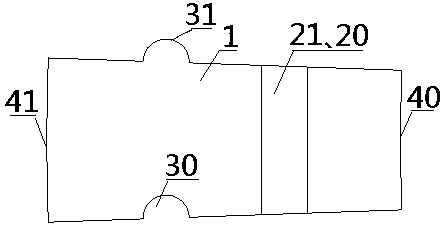

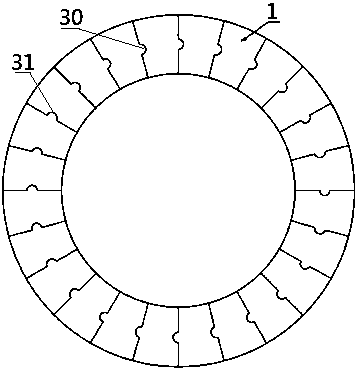

[0027] Embodiment two, such as figure 2 and 3 The whole side wall of the titanium tetrachloride fluidized chlorination furnace lining shown is circular, and the top surface and the bottom surface of the long trapezoidal flat edge brick 1 are the circle where the whole side wall of the titanium tetrachloride fluidized chlorination furnace lining is located. The center of the circle is the top convex arc surface and the bottom concave arc surface, and the middle horizontal groove 20 and the middle horizontal rib 21 are the middle horizontal straight groove and the middle horizontal straight rib (or the whole side wall of the titanium tetrachloride boiling chlorination furnace lining The center of the circle where it is located is the middle horizontal arc groove and the middle horizontal arc convex edge), and the middle vertical groove 30 and the middle vertical convex edge 31 are the middle vertical groove and the middle vertical convex edge.

[0028] Also can be described ti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap