Conductive asphalt concrete for healthy self-diagnosis on ballastless track and preparation method

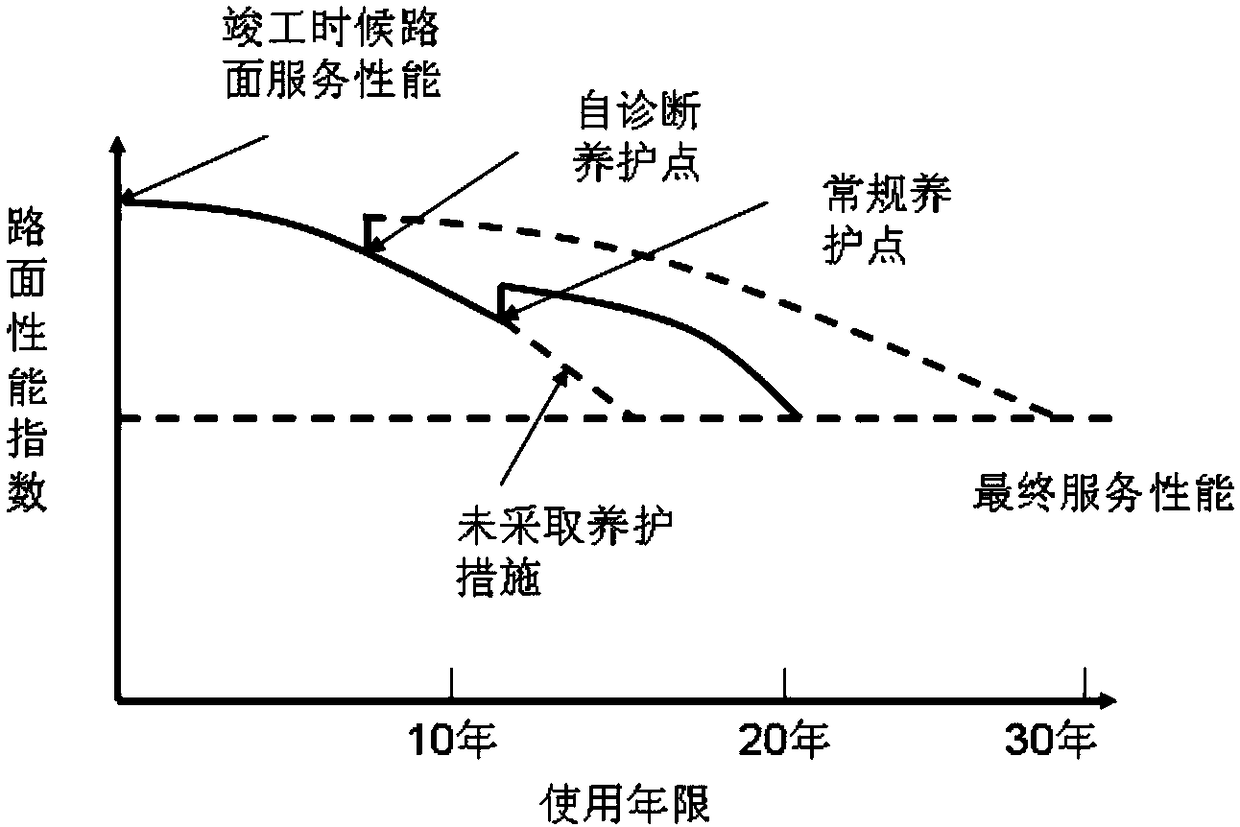

A technology of ballastless track and conductive asphalt, which is applied in the direction of track, road, ballast layer, etc., can solve the problems of unsafe health monitoring, time-consuming and labor-intensive, and inability to detect the settlement and deformation of the infrastructure under the track in time, so as to reduce maintenance costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Conductive asphalt concrete for health self-diagnosis of ballastless tracks consists of 100 parts of aggregate, 5.1 parts of asphalt, 18 parts of graphite, 1.5 parts of pitch-based carbon fiber, and 10 parts of mineral powder in terms of mass parts.

Embodiment 2

[0034] Conductive asphalt concrete for self-diagnosing the health of ballastless tracks consists of 100 parts of aggregate, 5.4 parts of asphalt, 22 parts of graphite, 1 part of pitch-based carbon fiber, and 10 parts of mineral powder in terms of mass parts.

Embodiment 3

[0036] Conductive asphalt concrete for self-diagnosing the health of ballastless tracks consists of 100 parts of aggregate, 5.8 parts of asphalt, 25 parts of graphite, 0.5 parts of pitch-based carbon fiber, and 10 parts of mineral powder in terms of mass parts.

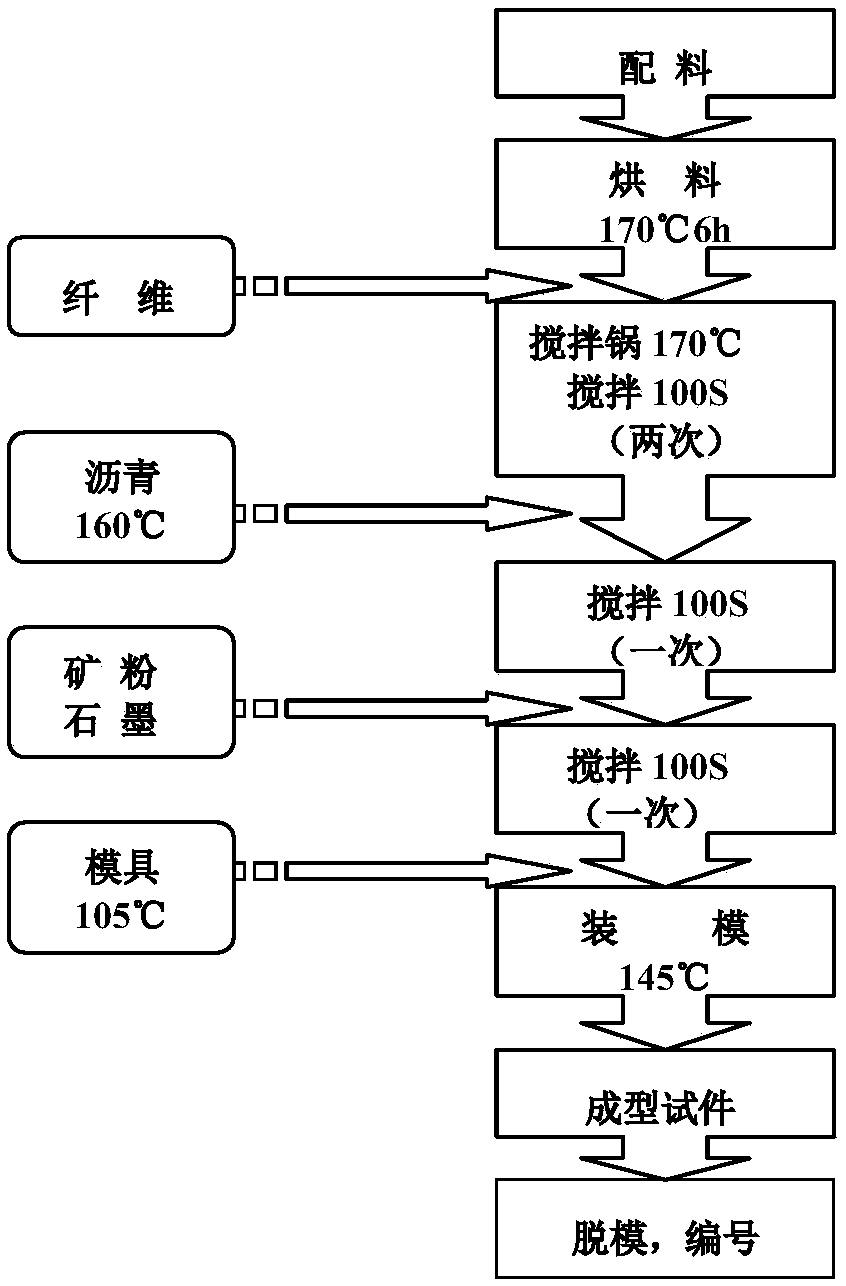

[0037] A method for preparing conductive asphalt concrete for self-diagnosing the health of ballastless tracks, the flow chart of which is as follows figure 1 As shown, follow the steps below:

[0038] Step 1. Prepare the quality of the required aggregate, and dry the aggregate at a temperature of 170°C for 6 hours;

[0039] Step 2. Add carbon fiber to the dried aggregate, and stir the mixture twice in a stirring pot at 170°C for 100 seconds each time;

[0040] Step 3. Continue to add 160°C asphalt to the mixture obtained in Step 2, and stir once in a stirring pot at 170°C for 100 seconds;

[0041]Step 4. Add mineral powder and graphite to the mixture obtained in Step 3, and stir once in a stirring pot at 170°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com