Low-melting-point Sn-Bi-Al series lead-free solder alloy material and preparation method thereof

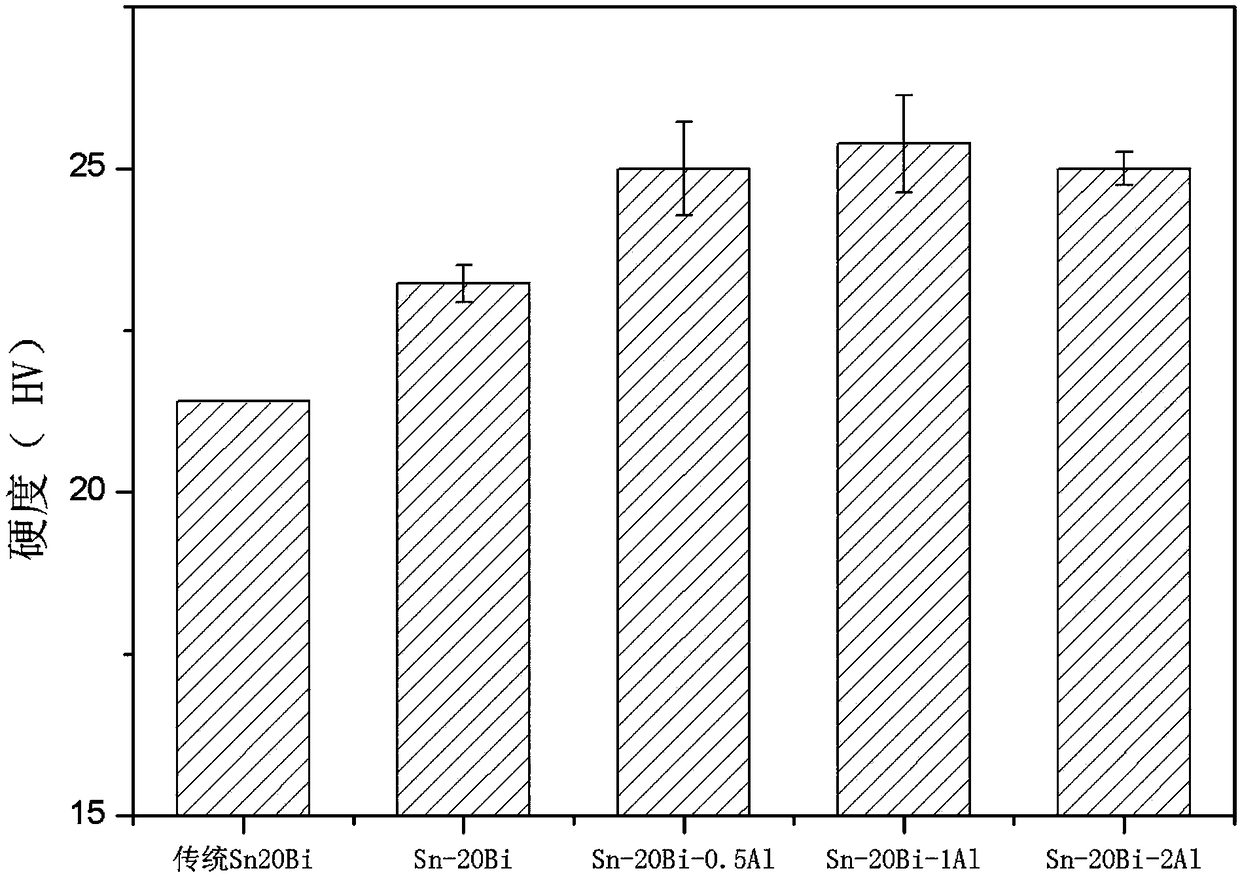

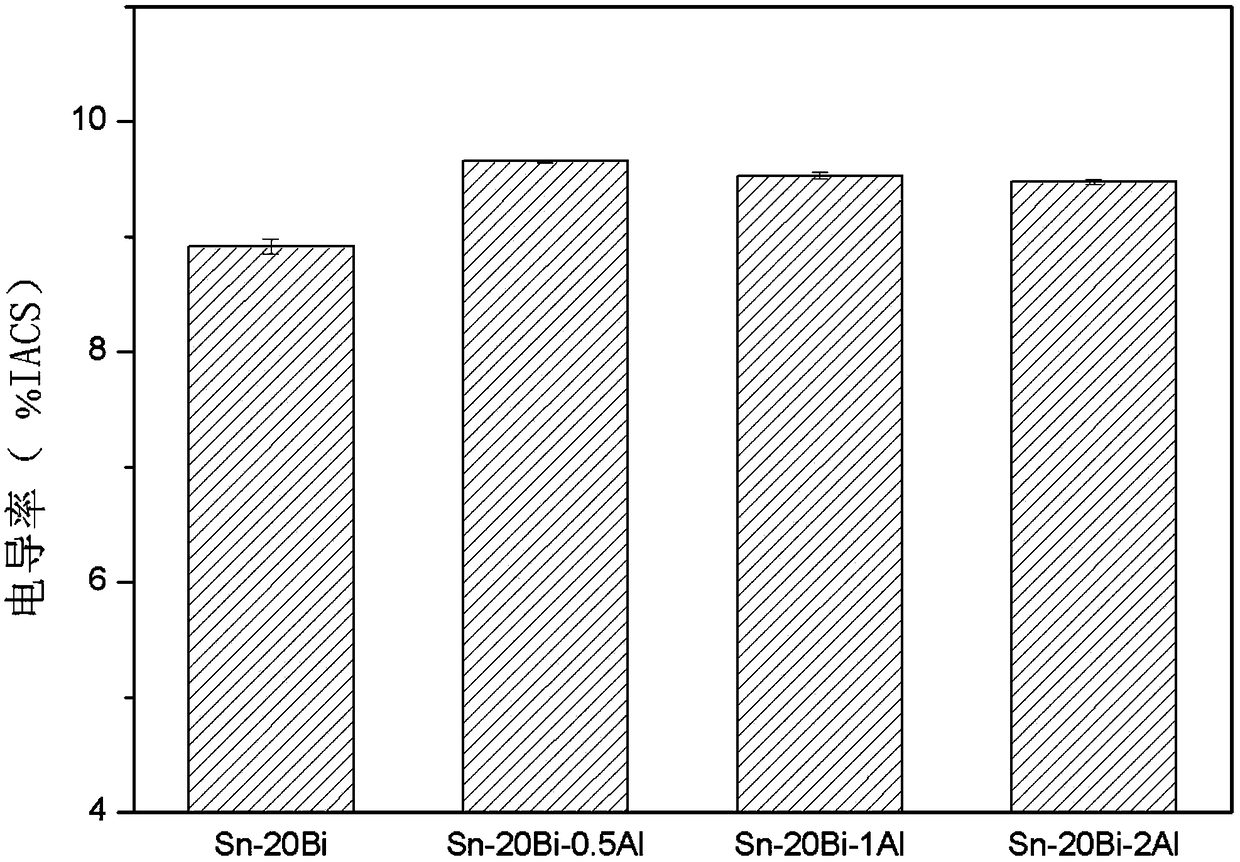

A lead-free solder alloy and lead-free solder technology are applied in the field of low-melting Sn-Bi-Al series lead-free solder alloy materials and their preparation, which can solve the problems that aluminum and tin-bismuth alloys are not easy to melt each other, and improve the microscopic The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

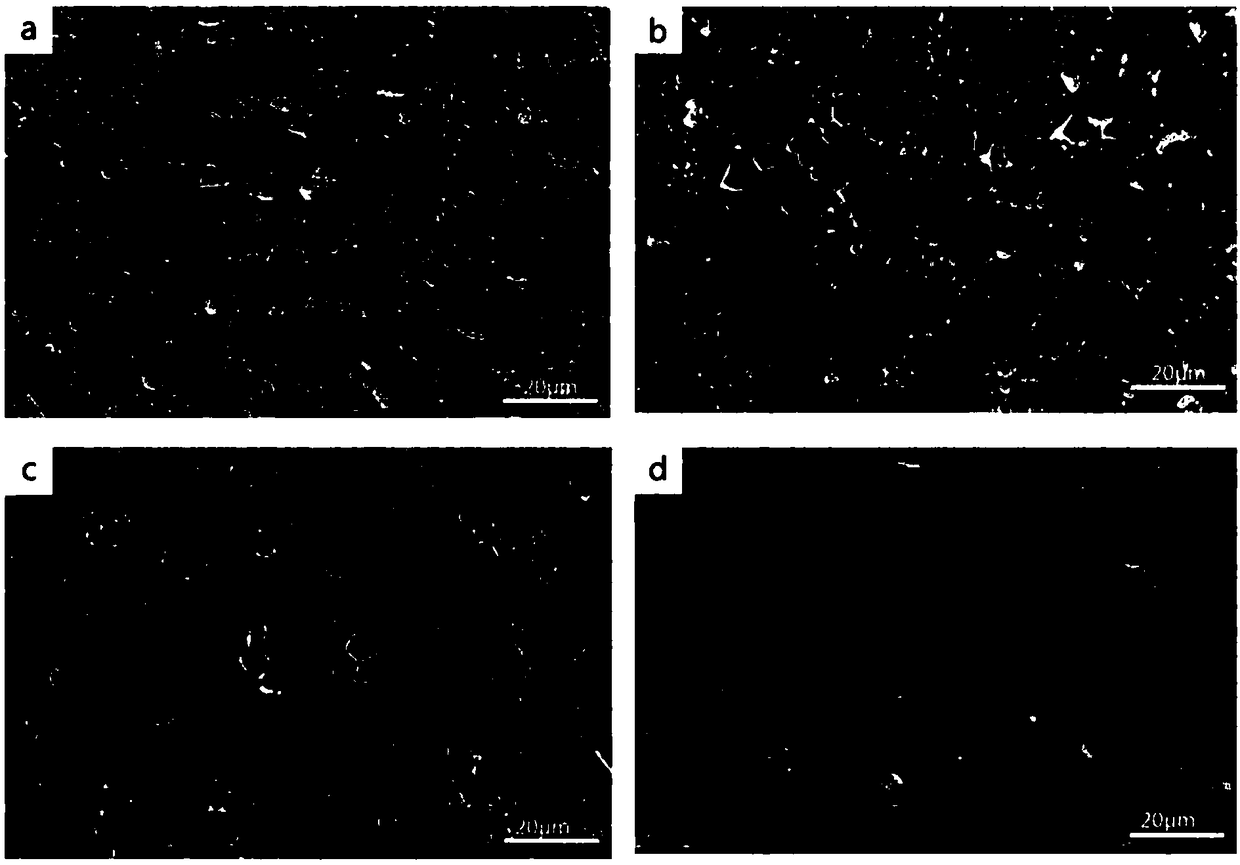

Image

Examples

Embodiment 1

[0032] (1) Weigh 16g of Sn powder and 4g of Bi powder into a ball mill jar.

[0033] (2) Add stainless steel balls, 3 large balls of φ20mm, 60 medium balls of φ10mm, and 90 small balls of φ6mm into the tank where the raw materials have been added; -3 Pa; then fill in an inert gas, and finally put it into a planetary ball mill for ball milling and mixing, the rotating speed is 150rad / min, and the ball milling time is 2 hours.

[0034] (3) Tablet the ball-milled powder, take the uniformly mixed powder and put it into a powder mold, and use a pressure of 80Mpa to uniaxially compact the powder into a metal tablet at room temperature.

[0035] (4) Put the pressed metal sheet into the copper crucible of the WK-II non-consumable electric arc furnace, and evacuate the electric arc furnace with a vacuum degree of 3×10 -3 Pa; refill with inert gas; vacuum again, repeat 2 times; finally melt under the protection of inert gas, the melting voltage is 220V, the melting current is 10A, keep...

Embodiment 2

[0038] (1) Weigh 0.10g of Al powder, 15.90g of Sn powder, and 4.00g of Bi powder into a ball mill jar.

[0039] (2) Add stainless steel balls, 3 large balls of φ20mm, 55 medium balls of φ10mm, and 80 small balls of φ6mm into the tank where the raw materials have been added; -3 Pa; then fill in an inert gas, and finally put it into a planetary ball mill for ball milling and mixing, the rotating speed is 180rad / min, and the ball milling time is 3 hours.

[0040] (3) Tablet the ball-milled powder, take the uniformly mixed powder and put it into a powder mold, and use a pressure of 90 MPa to uniaxially compact the powder into a metal tablet at room temperature.

[0041] (4) Put the pressed metal sheet into the copper crucible of WK-II non-consumable electric arc furnace, and vacuumize the electric arc furnace, and the vacuum degree is controlled at 4×10 -3 Pa; refill inert gas; then vacuumize, repeat 3 times; finally melt under the protection of inert gas, the melting voltage is ...

Embodiment 3

[0044] (1) Weigh 0.20g of Al powder, 15.80g of Sn powder, and 4.00g of Bi powder into a ball mill jar.

[0045] (2) Add stainless steel balls, 3 large balls of φ20mm, 50 medium balls of φ10mm, and 90 small balls of φ6mm into the tank where the raw materials have been added; -3 Pa; then fill in an inert gas, and finally put it into a planetary ball mill for ball milling and mixing, the rotating speed is 170rad / min, and the ball milling time is 4 hours.

[0046] (3) Tablet the ball-milled powder, take the uniformly mixed powder and put it into a powder mold, and use a pressure of 100Mpa to uniaxially compact the powder into a metal tablet at room temperature.

[0047] (4) Put the pressed metal sheet into the copper crucible of WK-II non-consumable electric arc furnace, and vacuum the electric arc furnace, and the vacuum degree is controlled at 5×10 -3 Pa; refill inert gas; then vacuumize, repeat 5 times; finally melt under the protection of inert gas, the melting voltage is 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap