Wavy thin steel plate-concrete combined hollow-section tubular pile and manufacturing method thereof

A thin steel plate and concrete technology, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of inability to reverse and cut soil construction, poor corrosion resistance, and high cost of steel pipe piles, achieving obvious application competitive advantages, Enhanced corrosion resistance and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

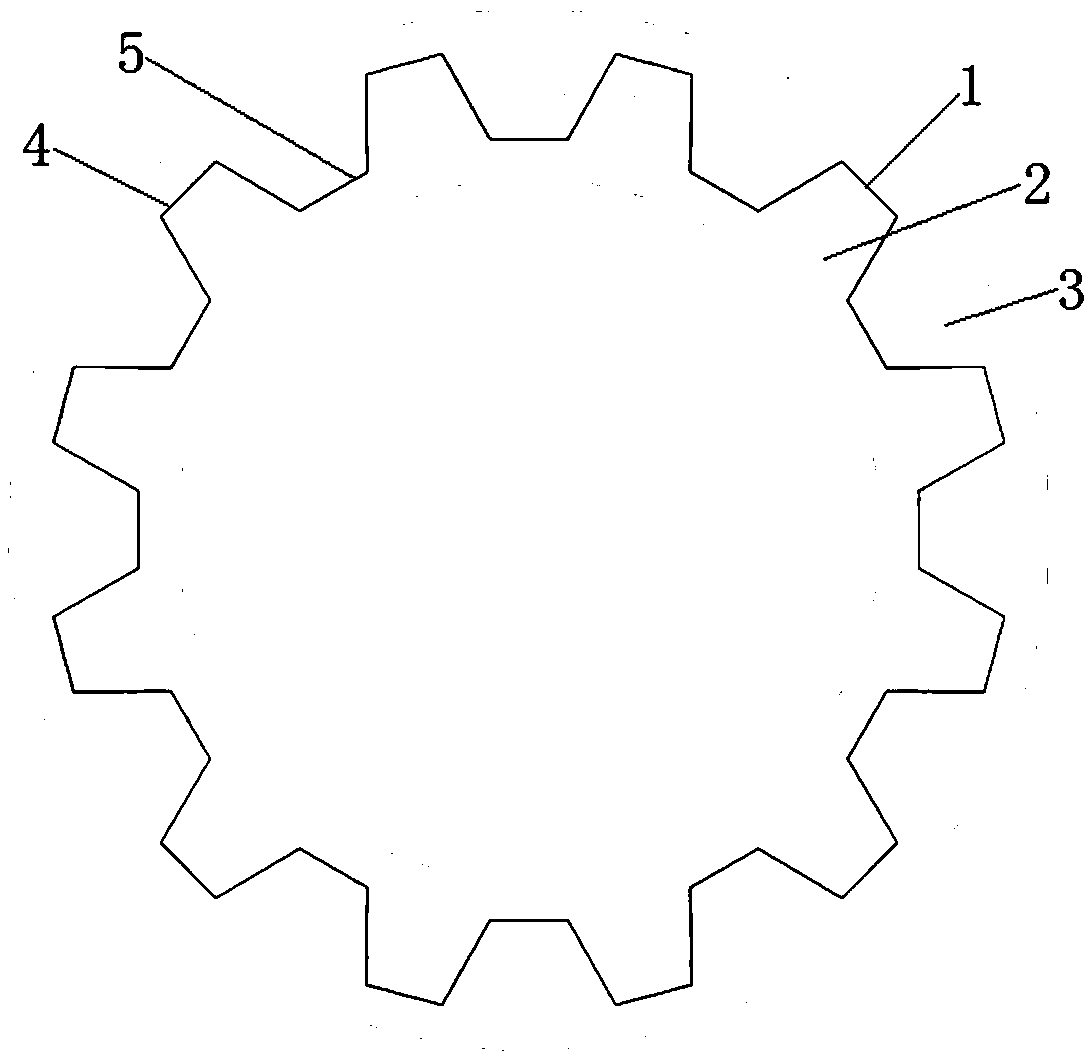

[0014] Example: such as figure 1 As shown, the main body of the corrugated thin steel plate-concrete composite hollow section pipe pile in this embodiment includes a corrugated thin steel plate 1, inner concrete 2 and outer concrete 3, and the combination of the three forms a pipe pile.

[0015] Such as figure 1 As shown, the corrugated thin steel plate 1 encloses a closed space, the inner concrete 2 is located inside the corrugated thin steel plate 1 , and the outer concrete 3 is located outside the corrugated thin steel plate 1 . A number of openings are provided on the corrugated thin steel plate 1, through which the inner concrete 2 and the outer concrete 3 are connected and the inner concrete 2 and the outer concrete 3 are integrated. At this time, the corrugated thin steel plate 1 is equivalent to being embedded in the concrete of the pipe pile; in this way, the corrugated thin steel plate 1 can increase the torsional and flexural strength of the pipe pile section, so t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap