3D printing wall robot and construction method for gob-side digging

A 3D printing and robot technology, which is applied in the fields of earthwork drilling, additive processing, shaft equipment, etc., can solve the problems of high labor intensity, easy slurry leakage, and slow construction speed, so as to improve the degree of mechanization and construction speed, without template effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

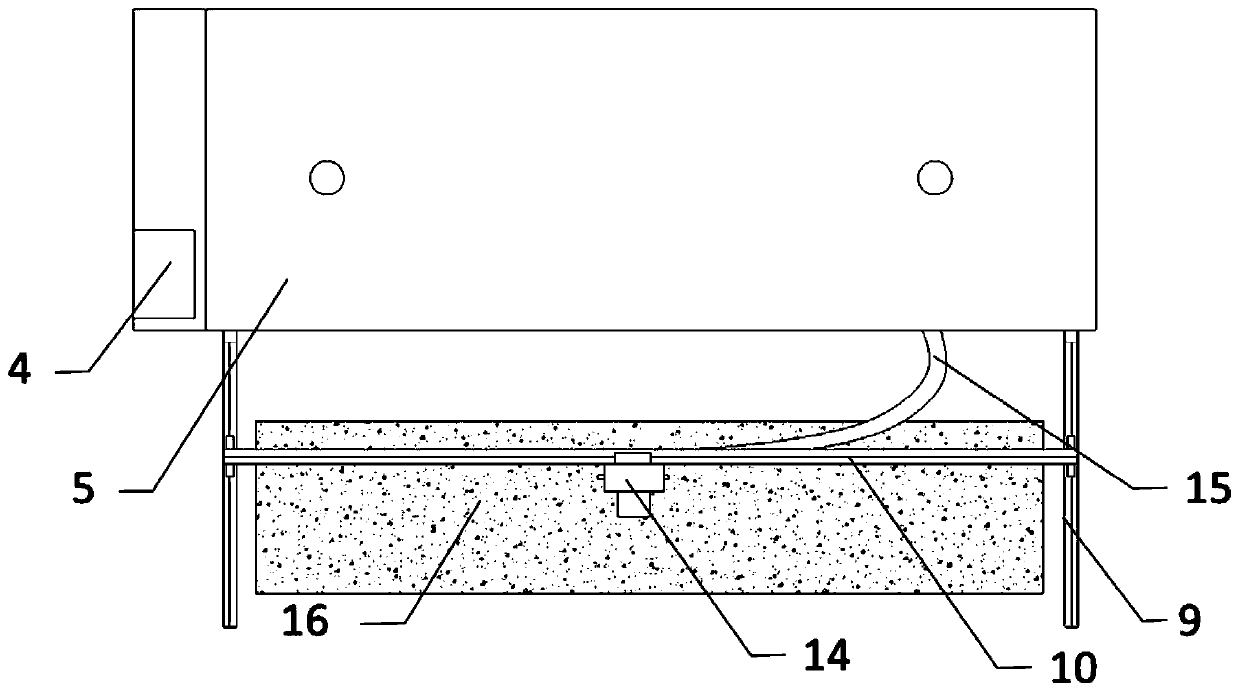

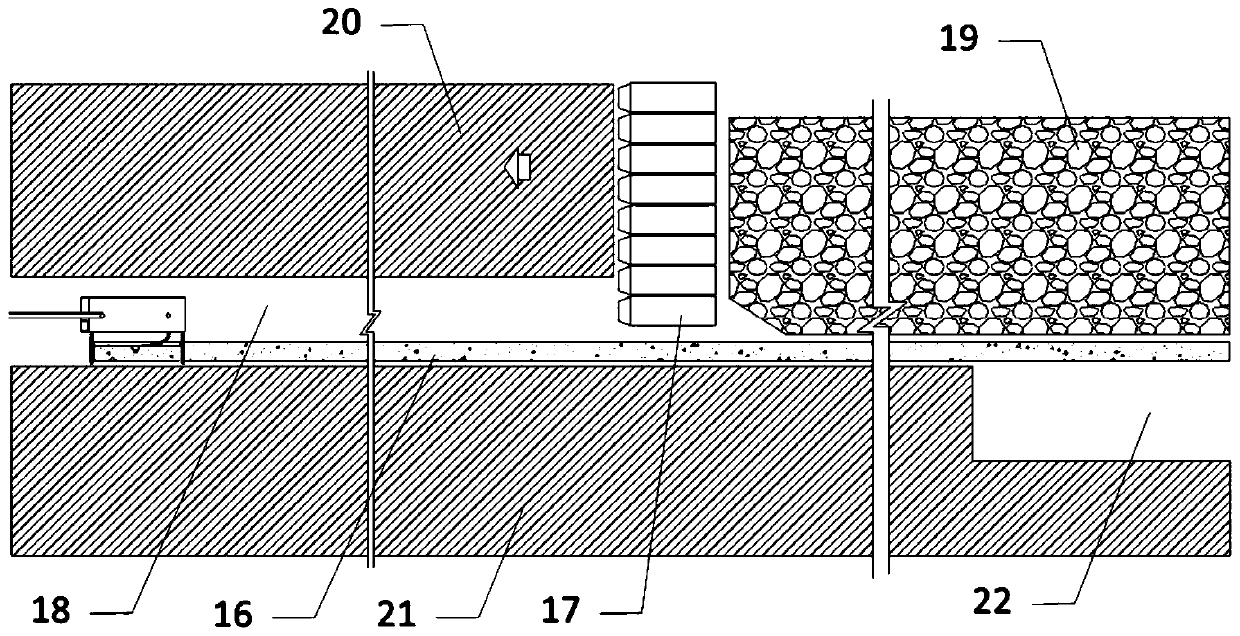

[0032] Such as Figure 1 to Figure 3 As shown, the 3D printing trough wall robot provided by the present invention includes a hydraulic walking system, a material storage system, a stirring and extruding system, a three-dimensional right-angle printer, a nozzle holder 13, a nozzle 14, a support system and Control system, the top of the hydraulic walking system is the stirring and extruding system, the storage system, and the 3D right-angle printer. Concrete three-dimensional body; wherein, the hydraulic walking system includes a rotating crawler chassis 1, a flat platform 2, a hydraulic system 3, a brake system and an operating system 4, the flat platform 2 is placed on the rotating crawler chassis 1, and the hydraulic system 3 is used for hydraulic walking System, material storage system and mixing and extruding system provide power, the operating system is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com