Clutch assembly for a drive train and gear system comprising such a coupling assembly

A technology for clutch components and drive trains, applied in electric clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve problems such as loss, and achieve the effects of low performance loss, minimized resistance loss, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

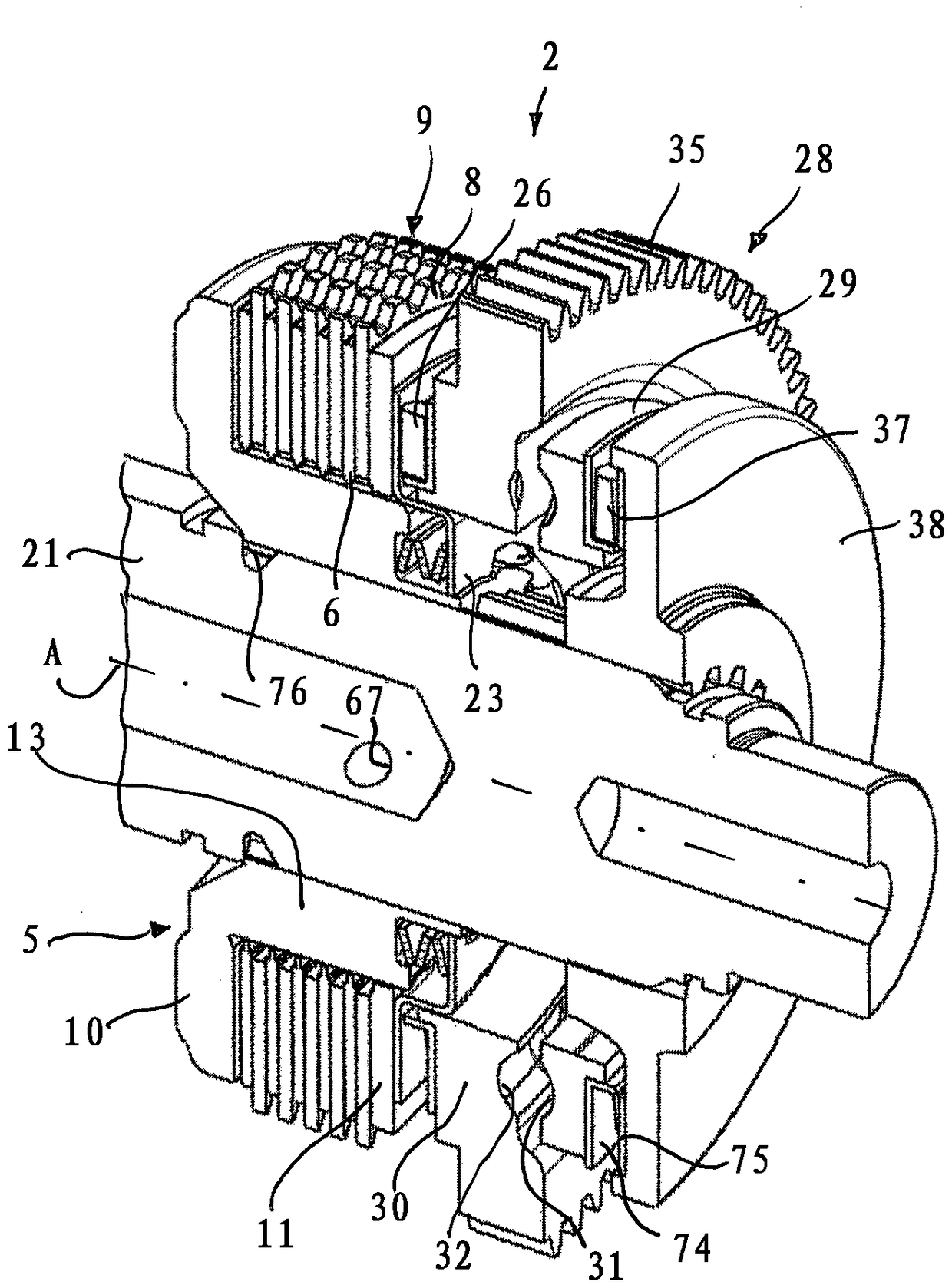

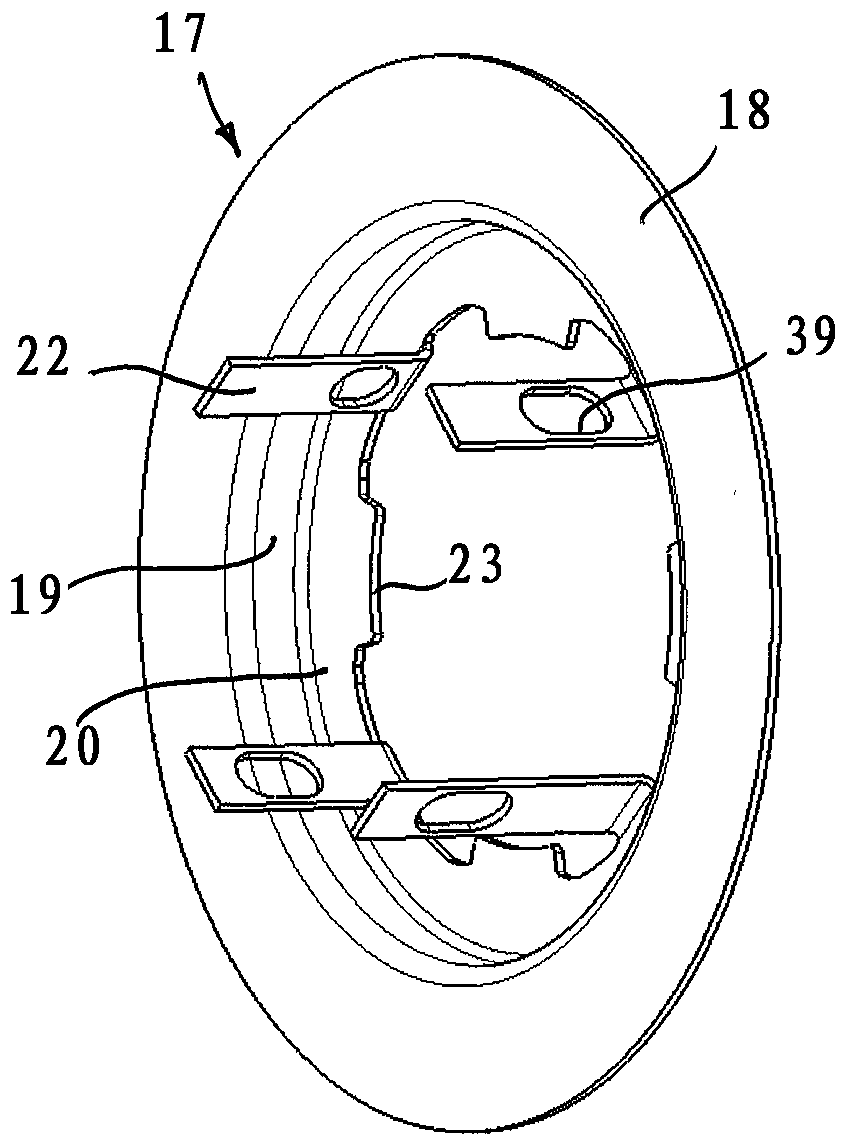

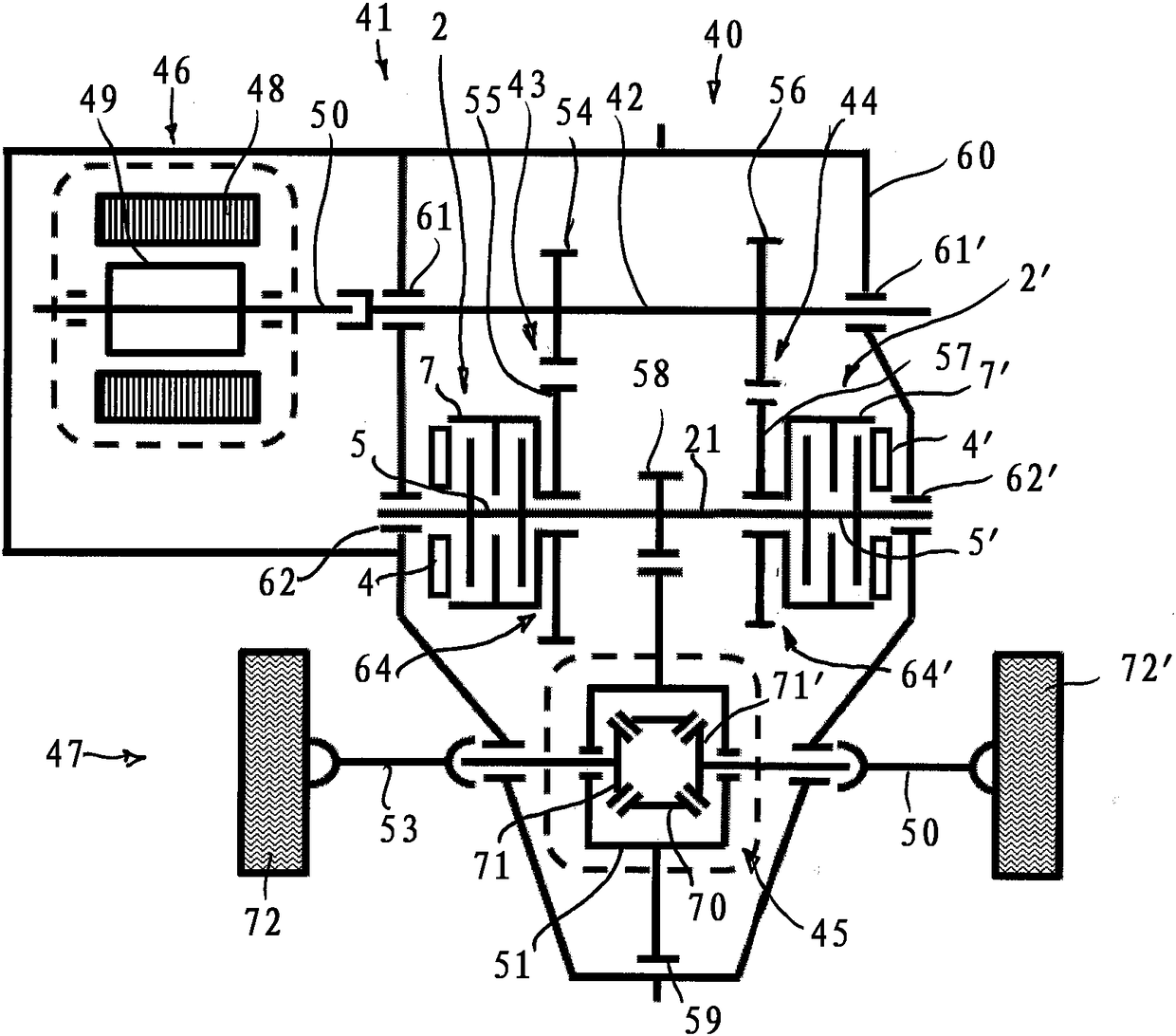

[0115] will describe together Figure 1 to Figure 6 A clutch assembly 2 of the invention for a drive train of a motor vehicle is shown. The clutch pack 2 comprises a friction plate clutch 3, and an operating device 4 for controlling the torque transmitted by the friction plate clutch. The friction plate clutch 3 is cooled and lubricated and can therefore also be referred to as a wet clutch. The clutch 3 is actuated by a device 4 which can also be called an actuating device.

[0116] The friction plate clutch 3 comprises an inner plate carrier 5 to which an inner plate 7 is connected in a rotationally fixed and axially movable manner, and an outer plate carrier 5 to which an outer plate 8 is connected in an axially movable and rotationally fixed manner. Plate carrier7. The outer plates 8 and the inner plates 6 are arranged so as to alternate in the axial direction and jointly form a plate pack 9 . The plate pack 9 is axially supported against the support plate 10 in a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com