Patrol control system for offshore boosting station

An offshore booster station, central controller technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as low efficiency of booster station inspections, reduce the number of inspections going out to sea, and reduce transportation costs. The effect of reducing maintenance costs and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

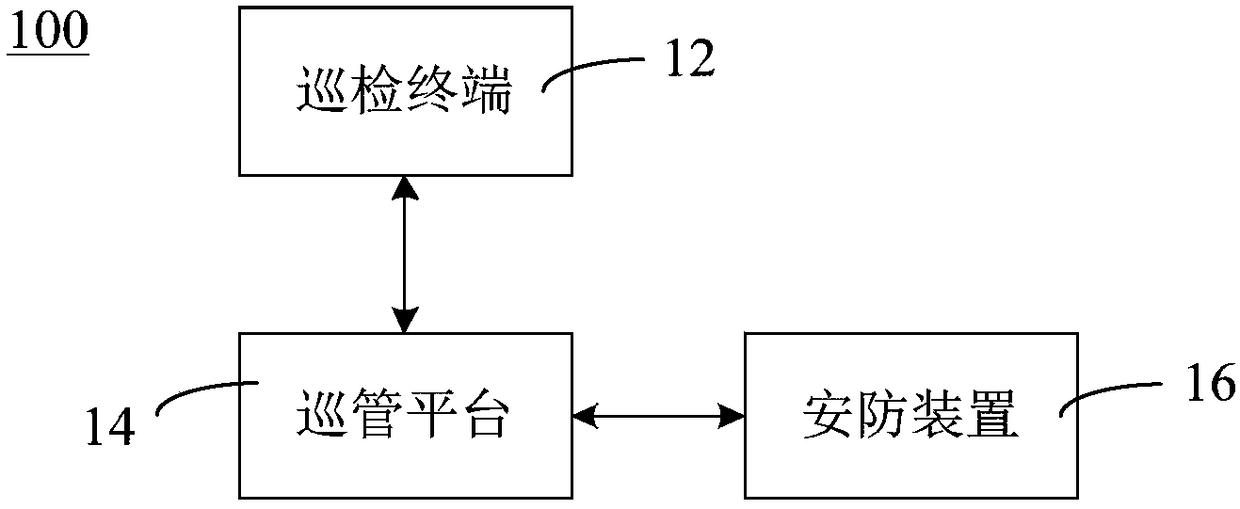

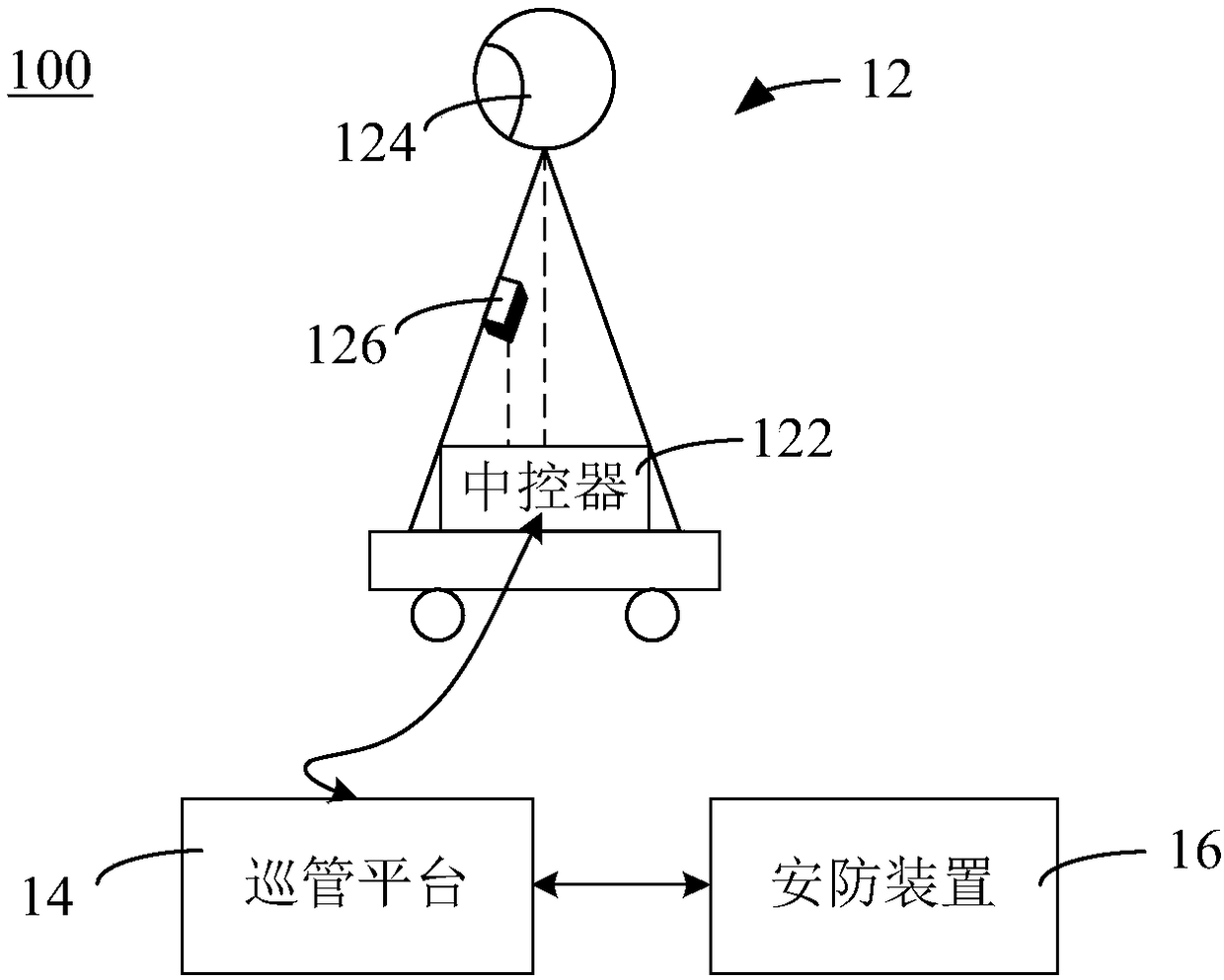

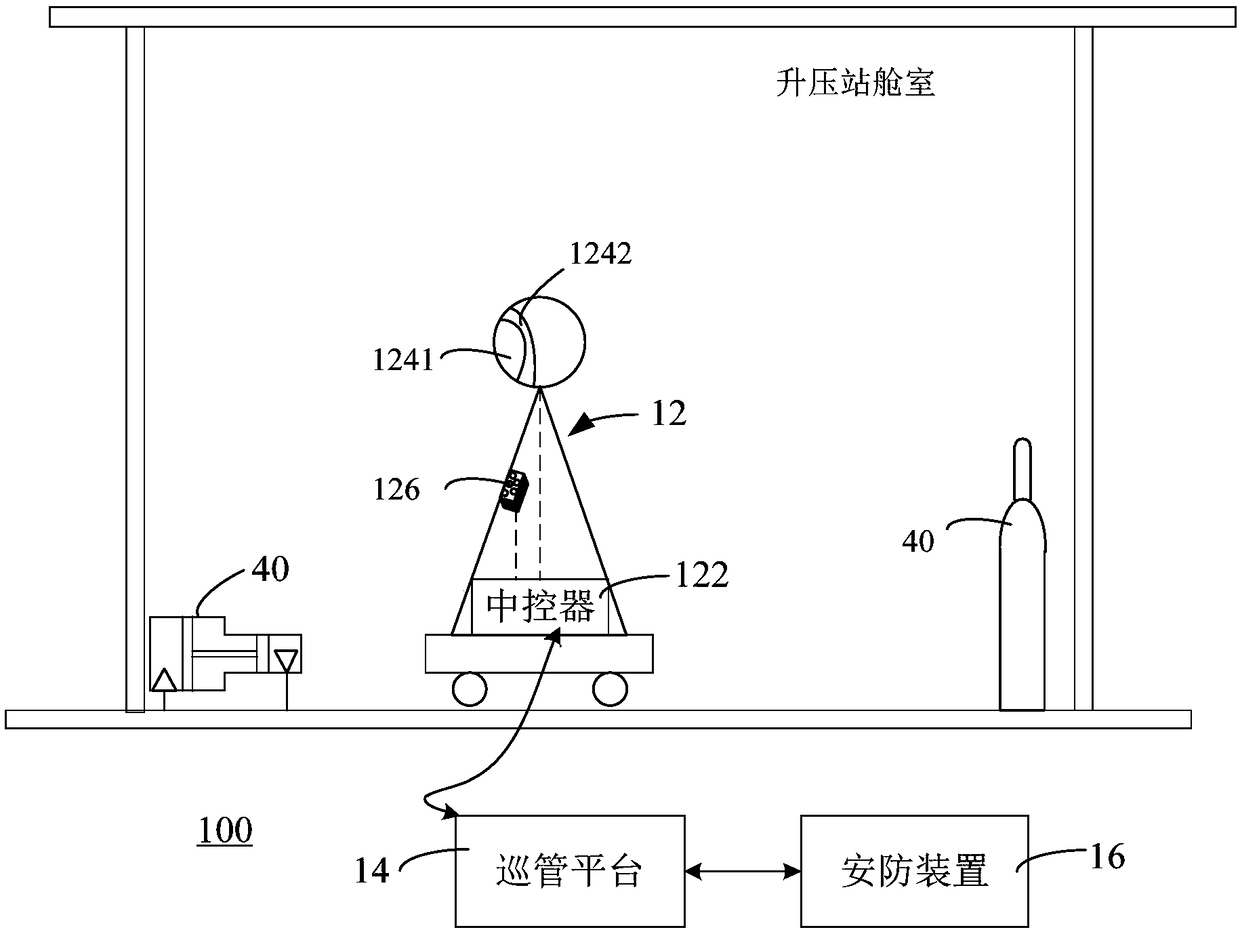

[0031] The following describes in detail the specific implementation of the offshore step-up station patrol control system of the present invention in conjunction with the accompanying drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

[0032] Offshore wind farms are widely distributed and the offshore climate environment is relatively harsh. The failure rate is higher than that of land farms, which often makes it difficult to carry out operational inspections of offshore wind farms, and the cost is high. The offshore booster station in the offshore wind farm is responsible for the transmission and distribution of electric energy produced by the entire farm, and is an important part of the operation and manage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com