Cylinder linear motor

A technology of linear motors and cylinders, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of permanent magnets losing magnetism and not being placed on the side of the motor at the same time, so as to improve the magnetic field force, simple structure, The effect of the simple structure of the secondary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

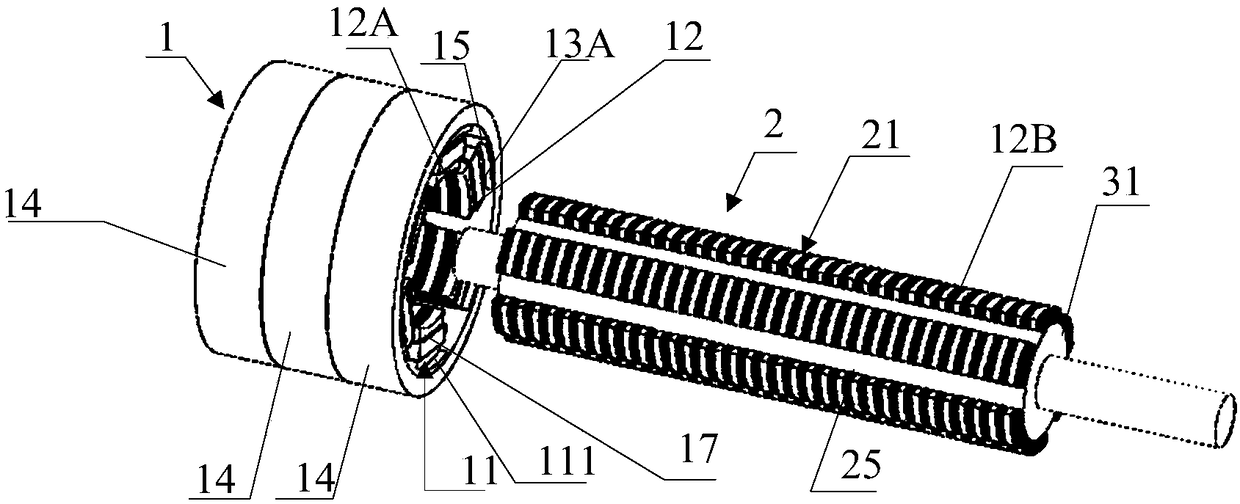

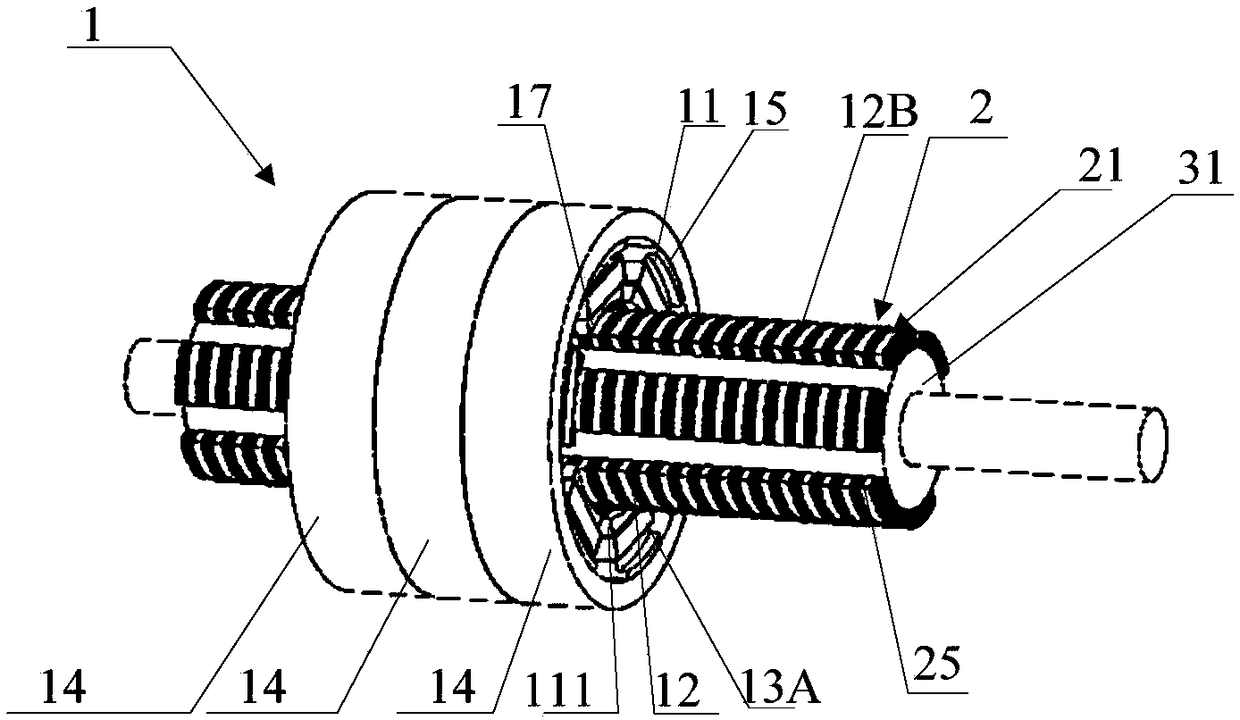

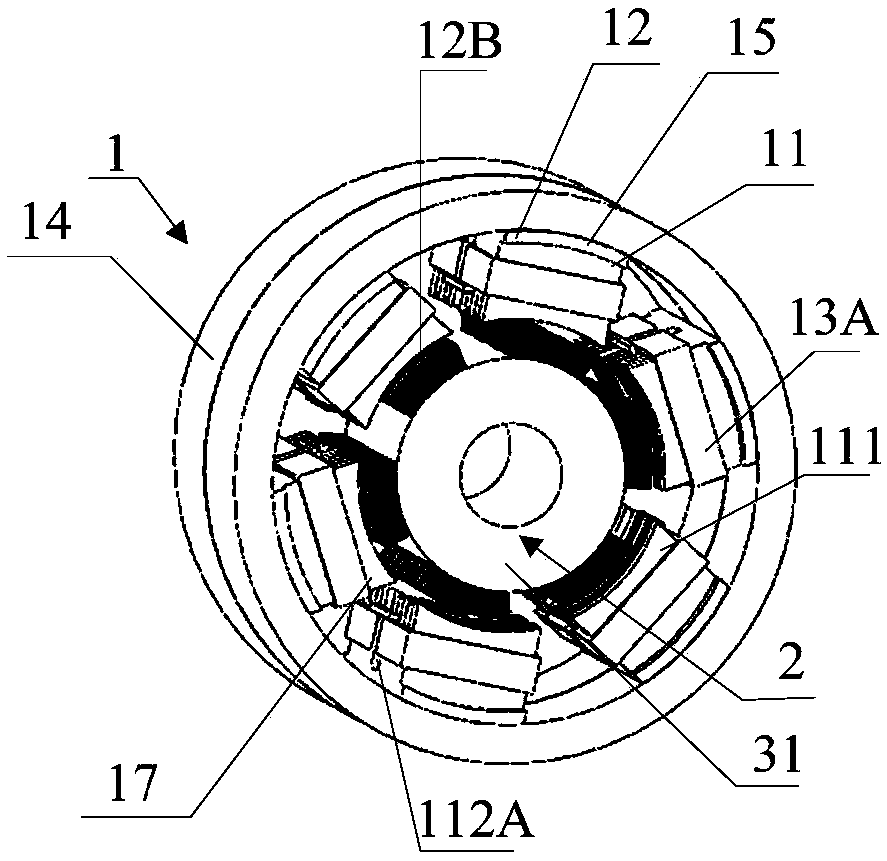

[0048] Such as figure 2 As shown, the present invention provides a cylindrical linear motor, which includes: a primary structure 1, a secondary structure 2, multiple sets of thirteenth salient pole structures 11, multiple third permanent magnets 12A, multiple The fourth permanent magnet 12B, a plurality of first windings 13A and a plurality of second windings 13B, the primary structure 1 and the secondary structure 2 are both cylindrical, and the primary structure 1 is surrounded by the secondary The outer side of the structure 2, the secondary structure 2 is arranged coaxially with the primary structure 1, and a plurality of the fourth permanent magnets 12B are installed on the outer wall of the secondary structure 2; the thirteenth salient pole structure One end of 11 is installed on the inner wall of the primary structure 1, and a plurality of the third permanent magnets 12A, a plurality of first windings 13A and a plurality of second windings 13B are all installed in a pl...

Embodiment 2

[0057] Such as figure 2 and Figure 8 As shown, on the basis of Embodiment 1, the primary structure 2 of this embodiment includes: a plurality of single-phase one-unit primary components 14; wherein, the non-magnetic material acts as a magnetic isolation and fixation for the primary components of each unit The role of connection. The single-phase one-unit primary part 14 is in the shape of a hollow ring, and the inner ring wall of the single-phase one-unit primary part 14 is provided with multiple sets of the thirteenth salient pole structures 11, and multiple sets of the thirteenth salient pole structures 11 are arranged. The salient pole structures 11 are arranged at equal intervals along the circumferential direction on the inner wall of the single-phase one-unit primary part 14 .

[0058] In the process of actual production and application, the number of units of the motor can be changed according to the demand, so the number of units of the actual motor can be set to m...

Embodiment 3

[0063] Such as Figure 12 to Figure 14 As shown, on the basis of Embodiment 1, the plurality of third permanent magnets 12A and the plurality of fourth permanent magnets 12B in this embodiment are all magnetized in the radial direction.

[0064] In order to make the magnetic density in the air gap close to a sine wave, the magnetization directions of each third permanent magnet 12A and each fourth permanent magnet 12B are not completely the same, but they are all magnetized along the radial direction, and each third permanent magnet 12A and each fourth permanent magnet 12B are magnetized in the radial direction. The schematic diagram of magnetization direction of four permanent magnets 12B is as Figure 12 As shown, the lower side of the leftmost third permanent magnet 12A in the figure can be N-level, the upper side of the leftmost third permanent magnet 12A in the figure can be S-level, and the remaining third permanent magnets 12A are arranged in the same way The bottom side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com