Application method of tundish for vacuum ingot casting

A tundish and ingot casting technology, used in foundry equipment, casting melt containers, mechanical cleaning, etc., can solve the problems of short residence time, uneven load bearing of tundish, unreasonable temperature distribution, etc., and achieve uniform load bearing and stable casting. , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

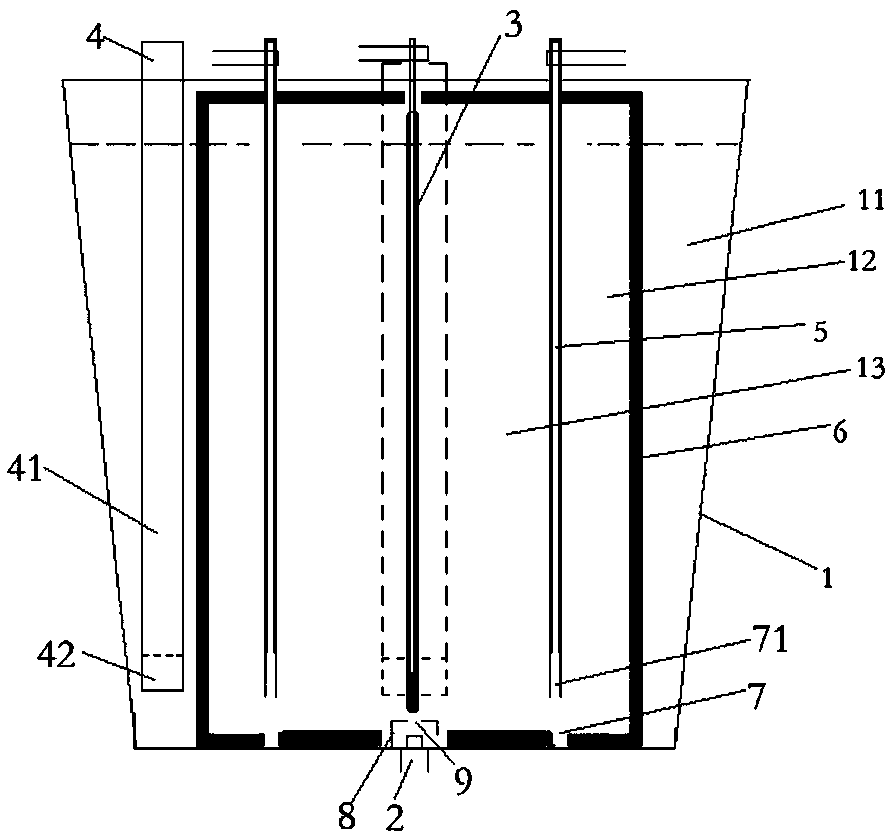

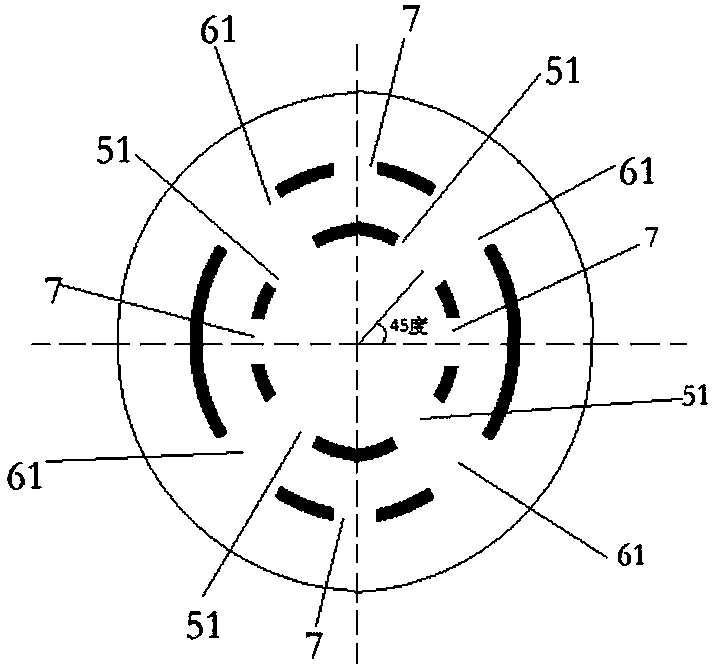

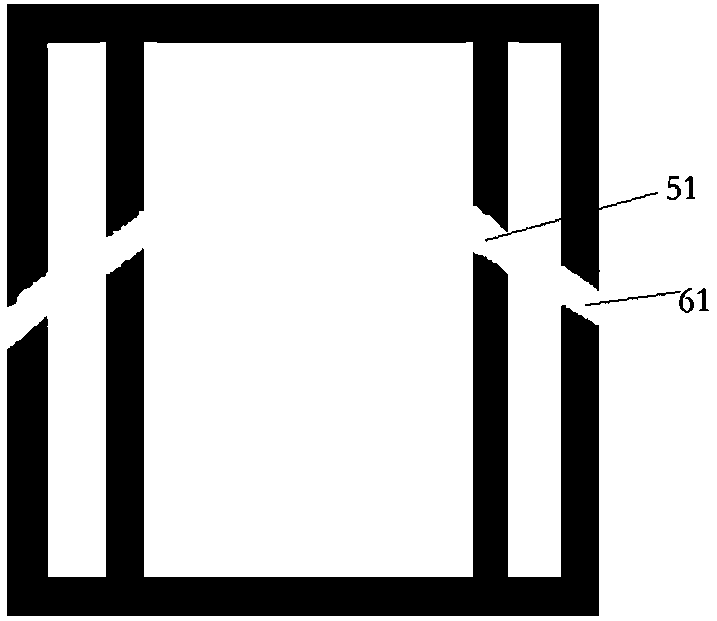

[0017] refer to figure 1 , 2 , 3, 4;

[0018] figure 2 The relative positional relationship of the steel discharge port 7 of the inner and outer slag retaining weirs, the inner steel passage 51 and the outer steel passage 61 is shown.

[0019] Before pouring the molten steel, the stopper device 3 is lowered to block the nozzle 2, the gate 71 is lowered, and the steel discharge port 7 is blocked; steel is poured, and the molten steel enters the tundish outer chamber 11 through the steel pouring inlet 4, the pouring channel 41 and the steel discharge channel 42, The molten steel gradually rises in the outer cavity 11 of the tundish, and the upward flow field causes the slag to float up; when the liquid steel level rises to the lower 1 / 2 height of the outer steel passage 61, the gate 71 is lifted to open the slag retaining weir 6 of the outer layer. The steel discharge port 7, the molten steel enters the middle cavity 12 of the tundish through the steel discharge port 7 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com