Reclaimed rubber aftertreatment system and treatment method

A technology of reclaimed rubber and rubber granules, which is applied in packaging and other directions, can solve the problems of easy bonding of regenerated rubber products, difficulty in realizing full automation, oxidation performance, etc., and achieve better cooling and isolation effects, high degree of automation, and uniform vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

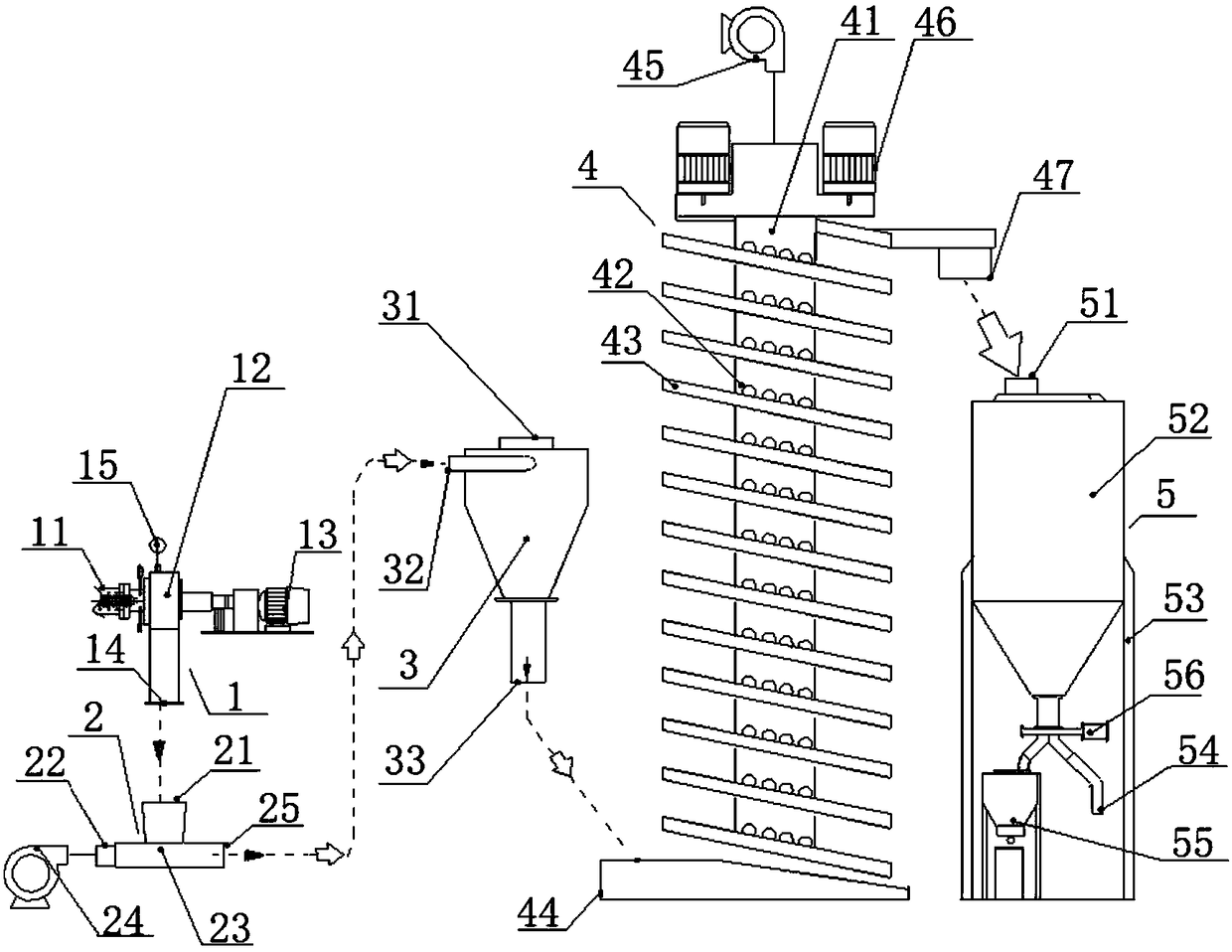

[0040] The regenerated rubber post-processing system of this embodiment includes a granulation device 1, a feeding device 2, a separation device 3, a cooling device 4 and a packaging device 5 arranged in sequence according to the process, wherein: the granulation device 1 cuts granules through its Blanking opening 14 is communicated with the feed opening 21 of feeding device 2, and described feeding device 2 is communicated with the feeding channel 32 of separating device 3 by its discharge port 25, and described separating device 3 is communicated with cooling by its discharging channel 33. The feed channel 44 of the device 4 communicates, and the cooling device 4 communicates with the feeding port 51 of the silo of the packaging device 5 through its cooled discharge opening 47 .

[0041] In the regenerated rubber post-processing system of this embodiment, in specific use, the granulation device 1 can be a granulator, and the rubber granules pass through the feeding device 2 a...

Embodiment 2

[0043] The regenerated rubber post-treatment system of the present embodiment, basic structure is the same as embodiment 1, and the improvement is: as figure 1 As shown, the granulator 1 includes an extruder 11 and a granulator 12. A water spray mechanism 15 is passed above the granulator 12. The water spray mechanism 15 can be a water spray pipe. One end of the granulator 12 passes through a joint The shaft is fixedly connected with the motor 13, and the other end communicates with the outlet of the extruder 11. With the use of the water spray mechanism 15, the water spray can cool down the granular regenerated rubber produced by cutting and form a water film on its surface, effectively preventing Bonded together and isolated from the air, preventing its performance from being oxidized by the air to reduce its performance, it has a double effect.

Embodiment 3

[0045] The regenerated rubber post-processing system of this embodiment has the same basic structure as that of Embodiment 2, and the improvement is that: the water spray mechanism 15 is a spray nozzle connected to a water source, and the water spray is even, the thickness of the "water film" is uniform, and the cooling and isolation effects are better. Preferably, the motor 13 is a variable frequency motor, and the motor speed is adjusted according to the particle size and feeding speed to improve its versatility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com