Glue injecting assembly used on injecting device as well as injection molding machine and injection molding method

An injection device and injection technology, which are applied to injection components, injection molding machines and injection molding fields, can solve problems such as increased manufacturing costs and waste of plastic raw materials, and achieve the effects of reducing flow time, saving raw materials, and fast filling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0051] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

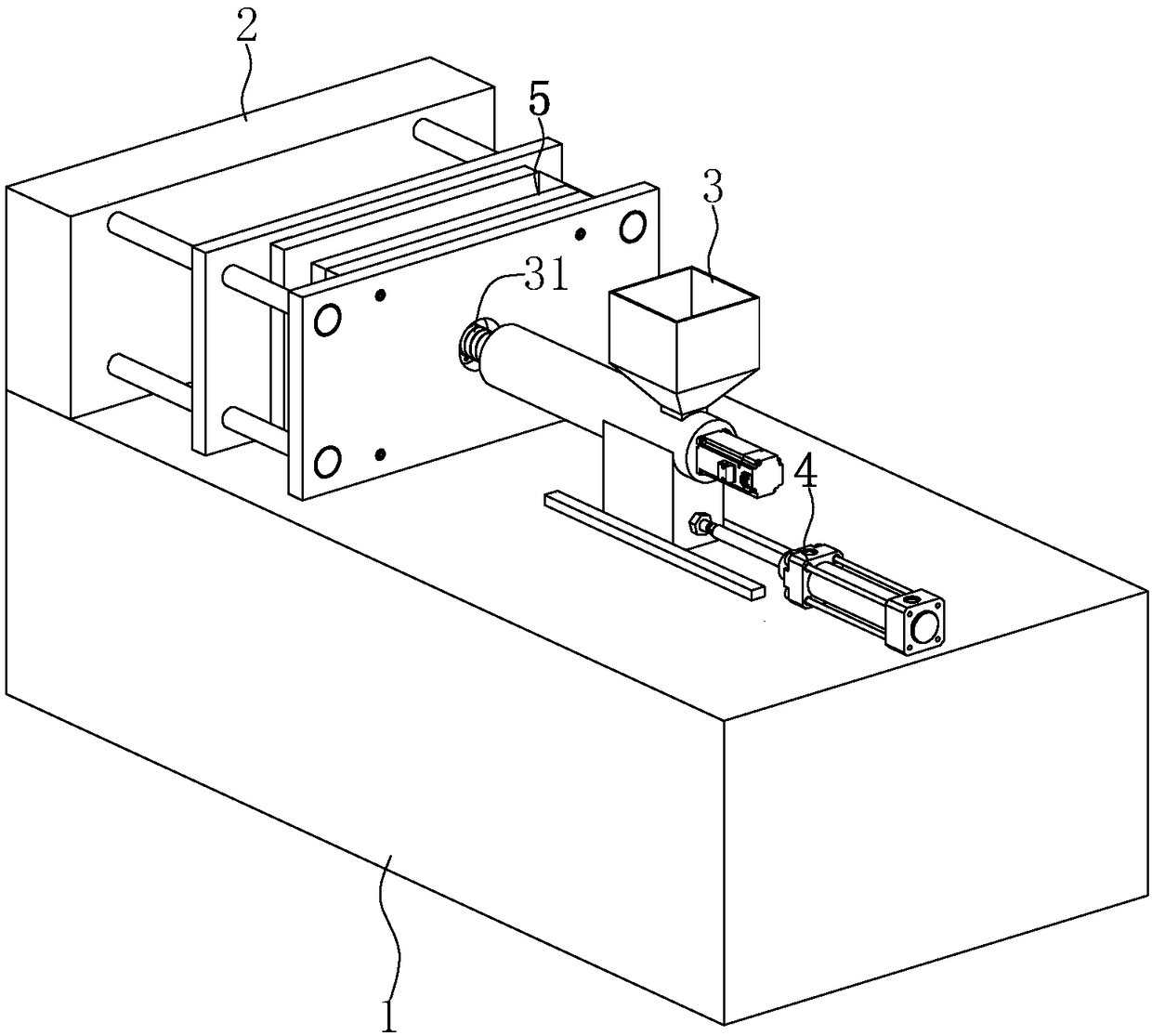

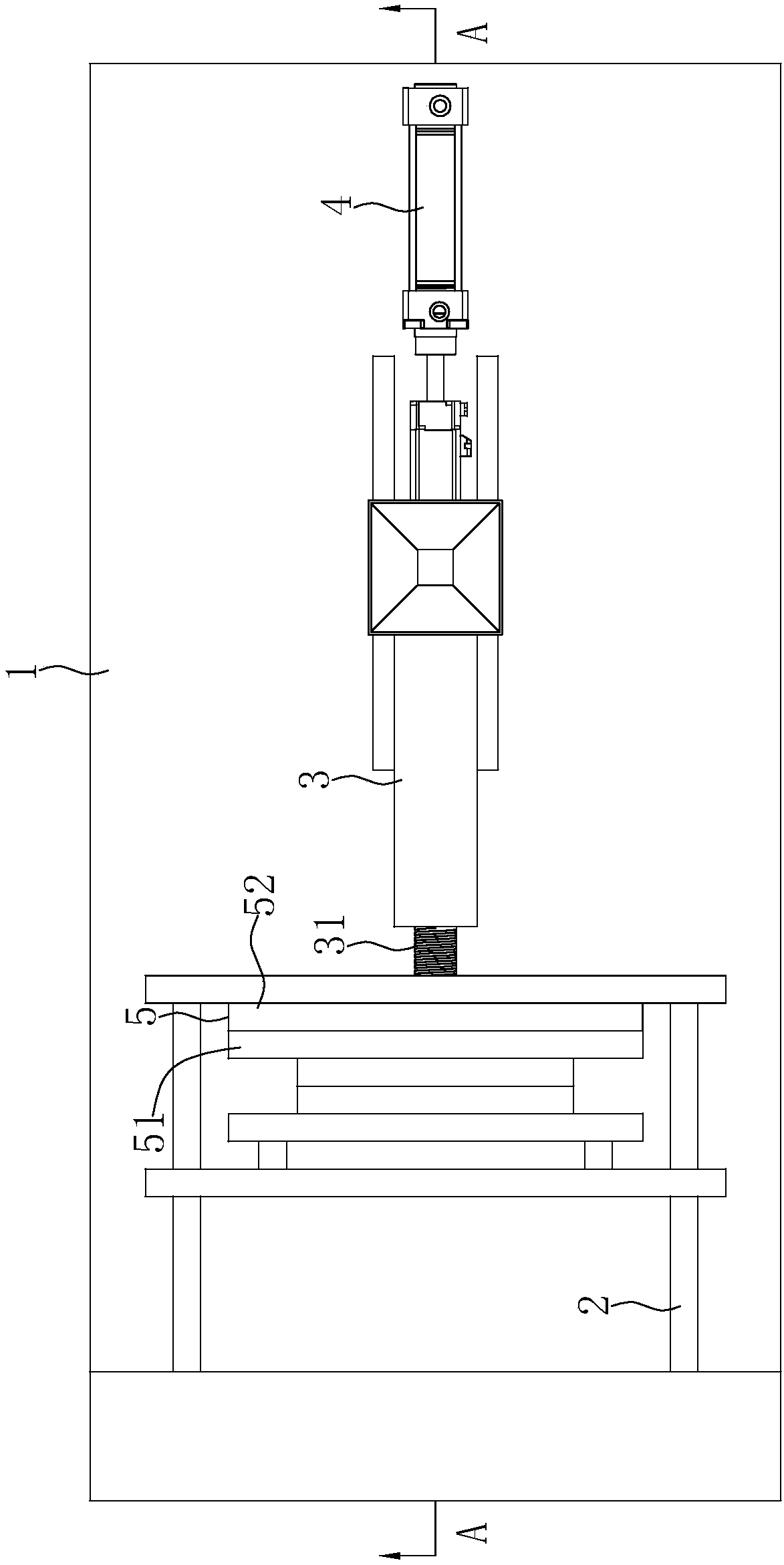

[0052] This embodiment relates to an injection molding machine, such as figure 2 As shown, it mainly includes: a body 1 , a mold clamping device 2 , an injection device 3 and a driving device 4 .

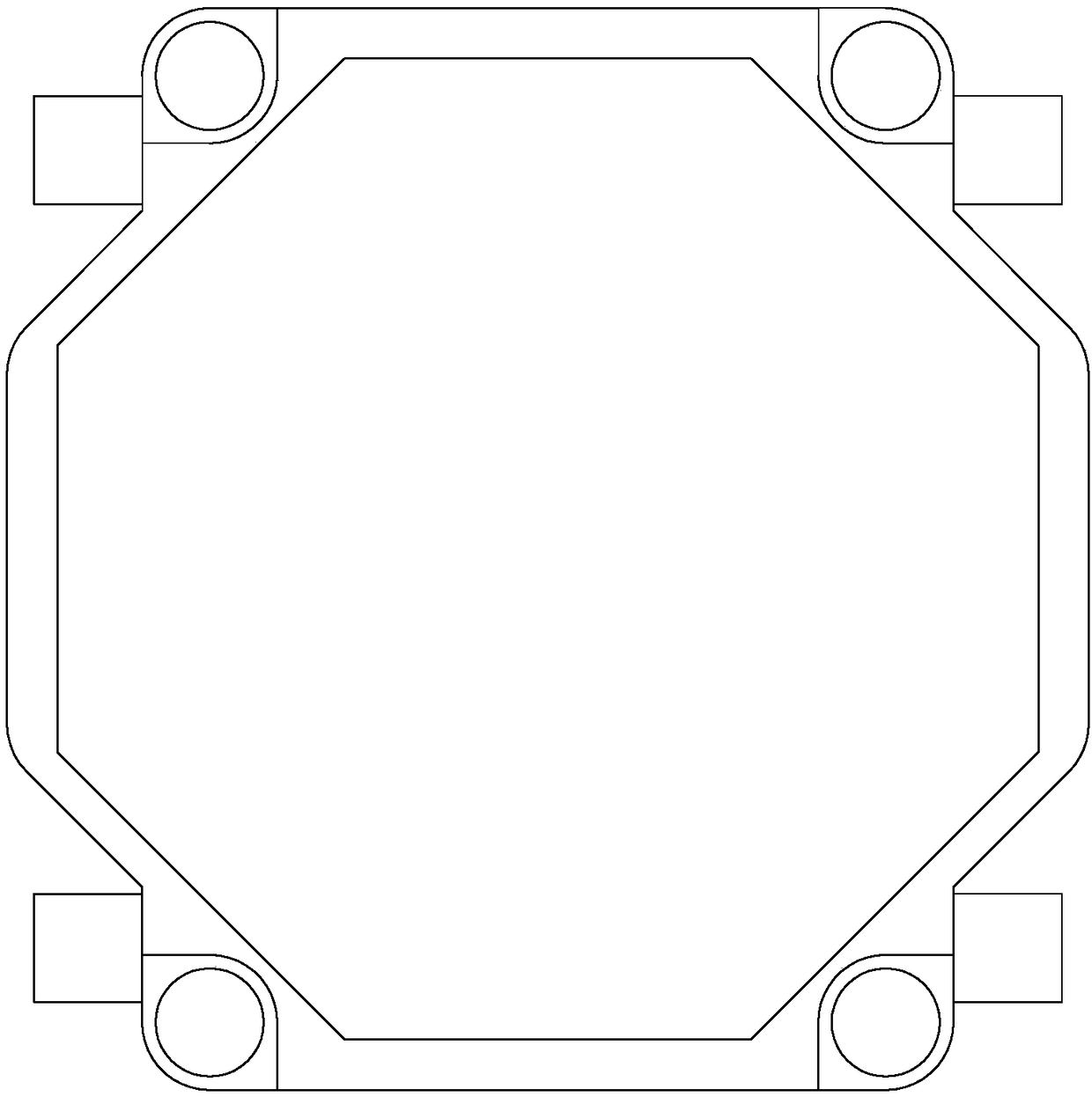

[0053] combine figure 1 As shown, the mold clamping device 2 is arranged on the fuselage 1, and the mold clamping device 2 is used to install the injection mold 5 and drive the injection mold 5 to open and close the mold. The injection device 3 is arranged on the body 1 and is provided with a plastic injection a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap