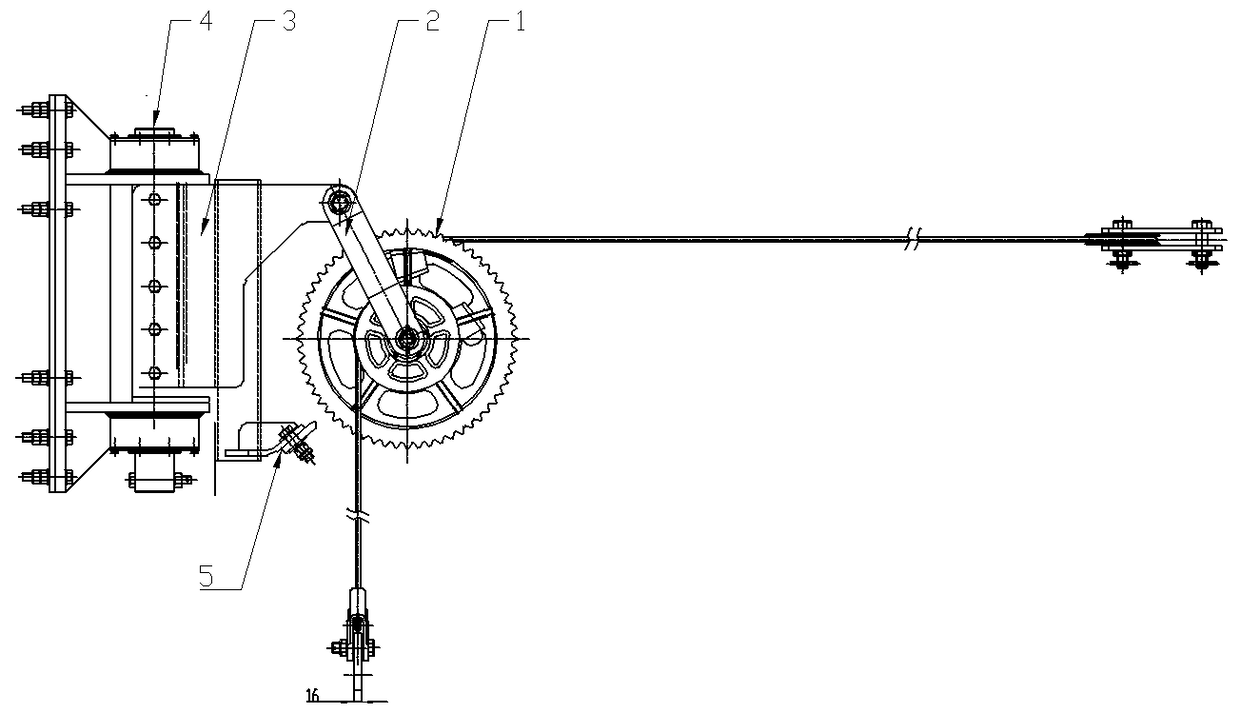

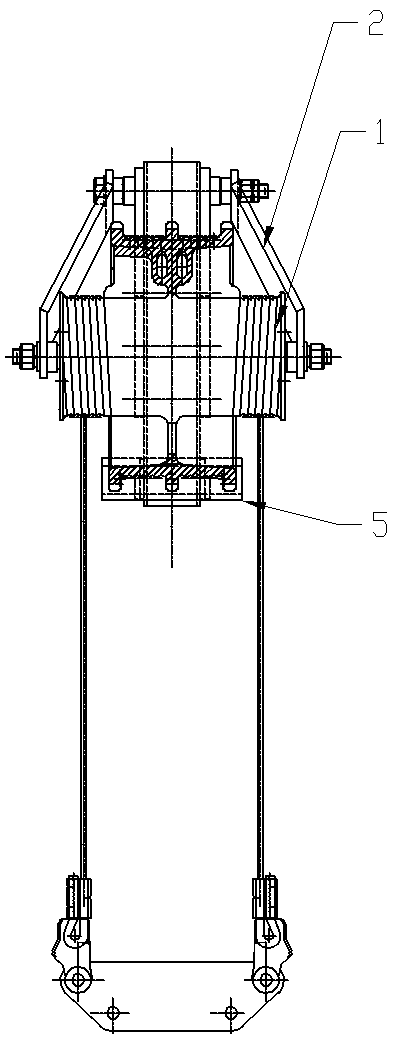

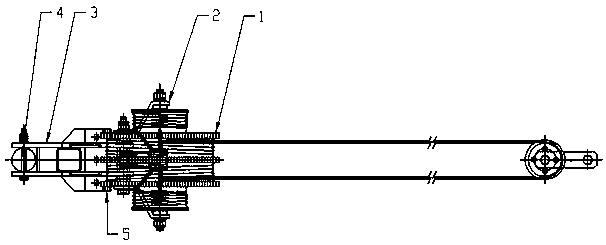

Double-winding-rope heavy load vertical tooth ratchet wheel compensation device used for overhead line system compensation anchorage

A catenary compensation and compensation device technology, applied in the direction of overhead lines, etc., can solve the problems that cannot meet the use of sections with limited space, ordinary ratchets cannot realize inverse ratio transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

[0031] The electrified high-speed railway catenary design system is designed for constant tension compensation. An anchoring device for compensation is installed at the end of each anchor section. At present, the ratchet compensation device is used in the design. It has a compact structure, high compensation efficiency and has a braking function. The product is more mature.

[0032] The adaptability of electrified railway catenary to train speed also depends on the tension and power supply capacity of the conductor. The higher the speed, the greater the tension. When the tension of the conductor is greater than 30kN, the terminal anchoring device does not meet the technical requirements, so a heavy-duty cable must be designed. Type ratchet compensation device.

[0033] In the busy route of cargo transportation, in order to improve the efficiency of transportation capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com