Coating with wall-surface effect of simulated yellow mud cracks and preparation method of coating

A mud and crack technology, which is applied to the coating and its preparation field of imitating yellow mud crack wall effect, can solve the problems of uneven crack effect, difficult construction, low strength, etc., and achieves clear and natural crack texture, good market prospect, Good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

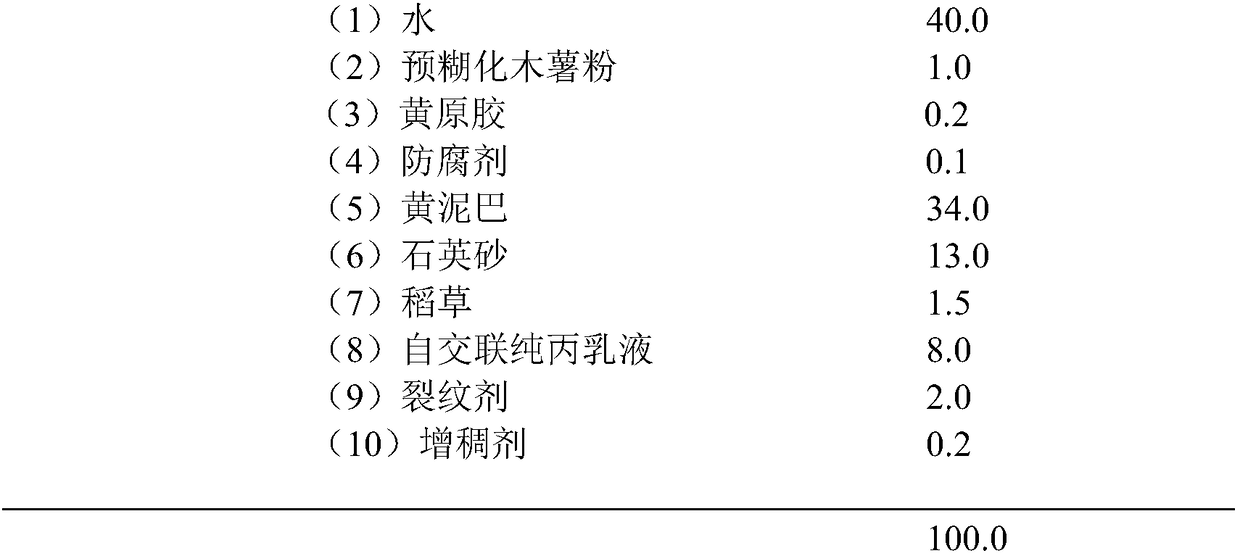

Embodiment 1

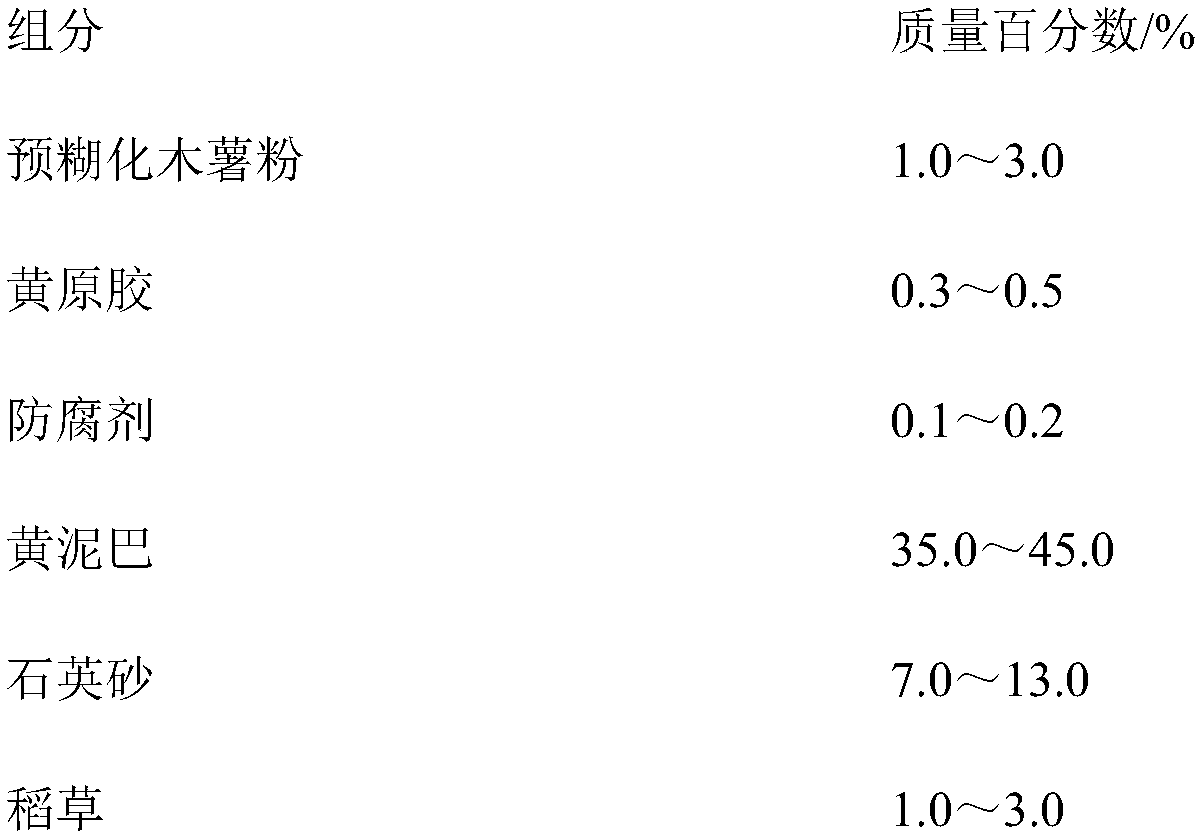

[0024] composition:

[0025]

[0026] Put water into the paint tank first, add pre-gelatinized cassava flour, xanthan gum and preservatives in the form of dust under stirring, and disperse at a high speed of 1800 rpm / min for 15-20 minutes, so that it can be fully dissolved into a uniform and transparent glue , add yellow mud, quartz sand, straw, mix and stir evenly, add self-crosslinking pure acrylic emulsion, cracking agent and disperse evenly at high speed at 1800rpm / min. Then add a thickener to adjust the viscosity, and pack after passing the test.

Embodiment 2

[0028] composition:

[0029]

[0030]

[0031] The preparation method of the coating with the imitation yellow mud crack wall effect in Example 2 is the same as that in Example 1.

Embodiment 3

[0033] composition:

[0034]

[0035] The preparation method of the coating with the imitation yellow mud crack wall surface effect in embodiment 3 is the same as that in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com