Nano-fiber melt-blowing equipment

A nanofiber and meltblown technology, applied in the field of ultra-thin material production equipment, can solve the problems of polluting the environment, affecting production quality, harming physical health, etc., and achieving the effect of scientific and reasonable structure, convenient and efficient heat dissipation, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

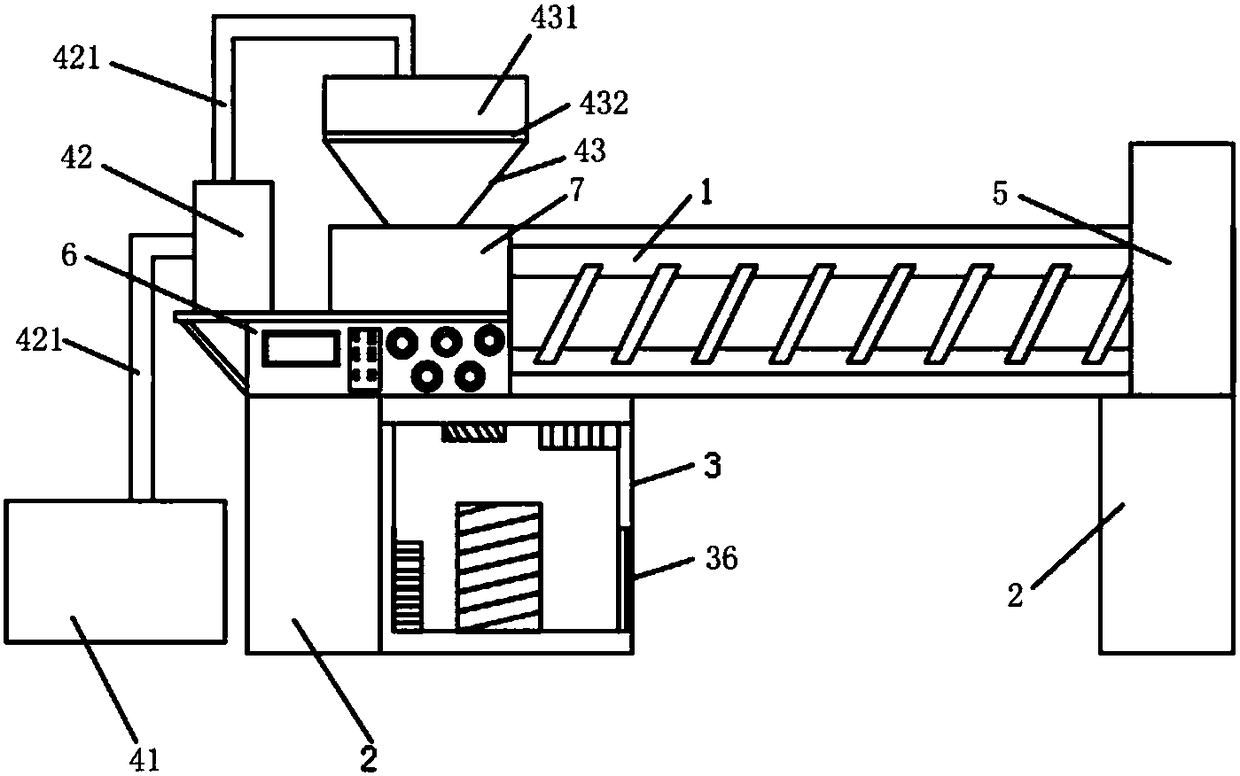

[0021] Such as figure 1 As shown, the nanofiber melt-blown equipment of the present invention includes a melt-blown machine body 1, a support frame 2 of a quadrilateral frame structure that supports the melt-blown machine body 1, and in the support frame 2, below the melt-blown machine body 1 The outer side of the control box 3 and the support frame 2 close to the feed port of the melt blown machine body 1 is provided with a feeding device 4, and the outer cover at the discharge port of the melt blown machine body 1 is used to prevent the waste generated during the melt blown process from polluting the working environment , the protective cover 5 that damages the health of the staff and the control panel 6 that is arranged on the front side of the melt blown machine body 1 .

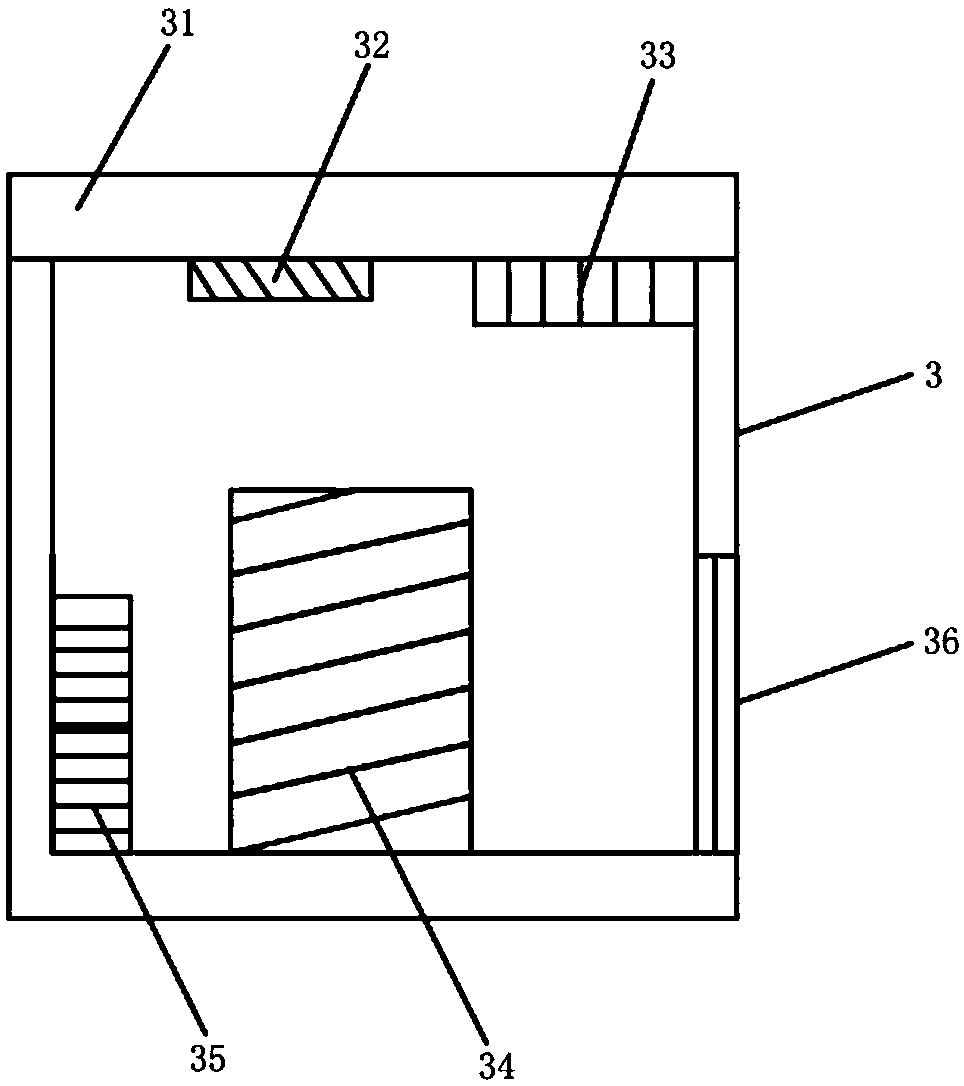

[0022] The top surface of the control box 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com