A continuous vacuum diffusion furnace

A technology of vacuum diffusion and furnace door, which is applied in the direction of diffusion/doping, polycrystalline material growth, crystal growth, etc., and can solve the problems of limited expansion of furnace capacity, improvement of efficiency, unfavorable process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that specific embodiments are only detailed elaborations of the present invention, and its purpose is to enable those skilled in the art to better understand and implement the present invention. regarded as a limitation of the present invention.

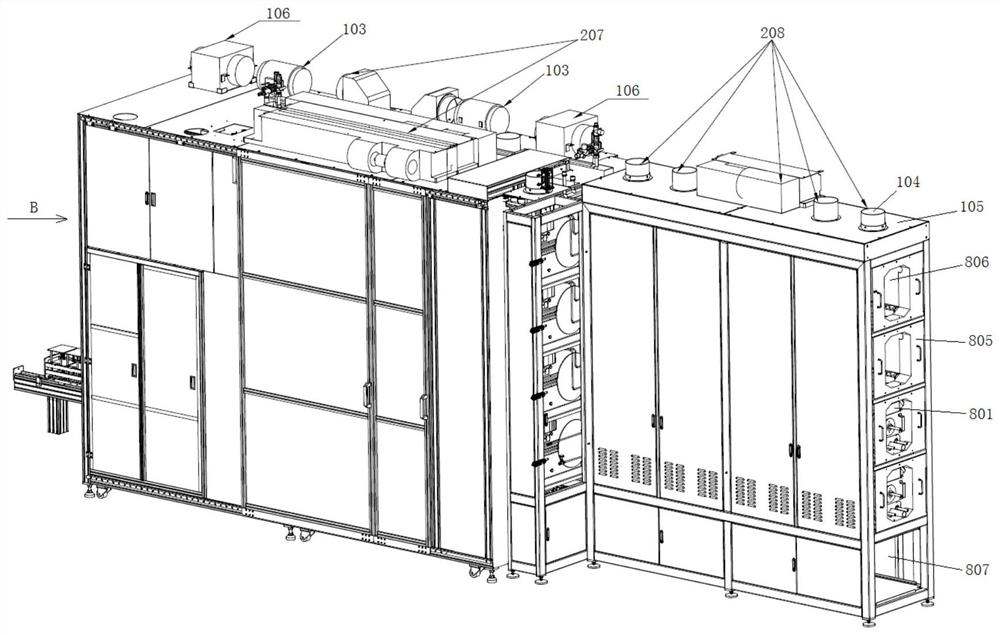

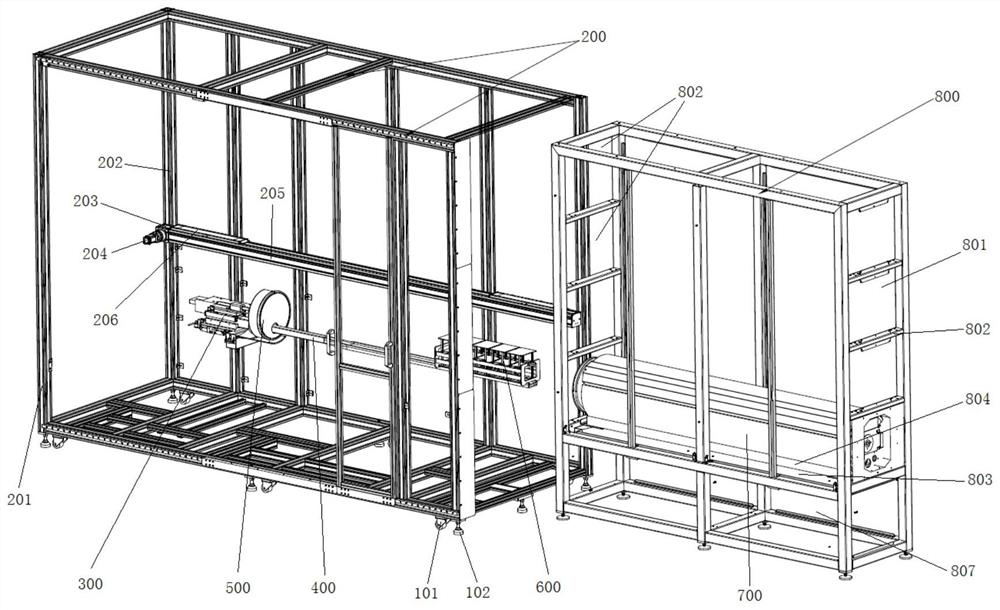

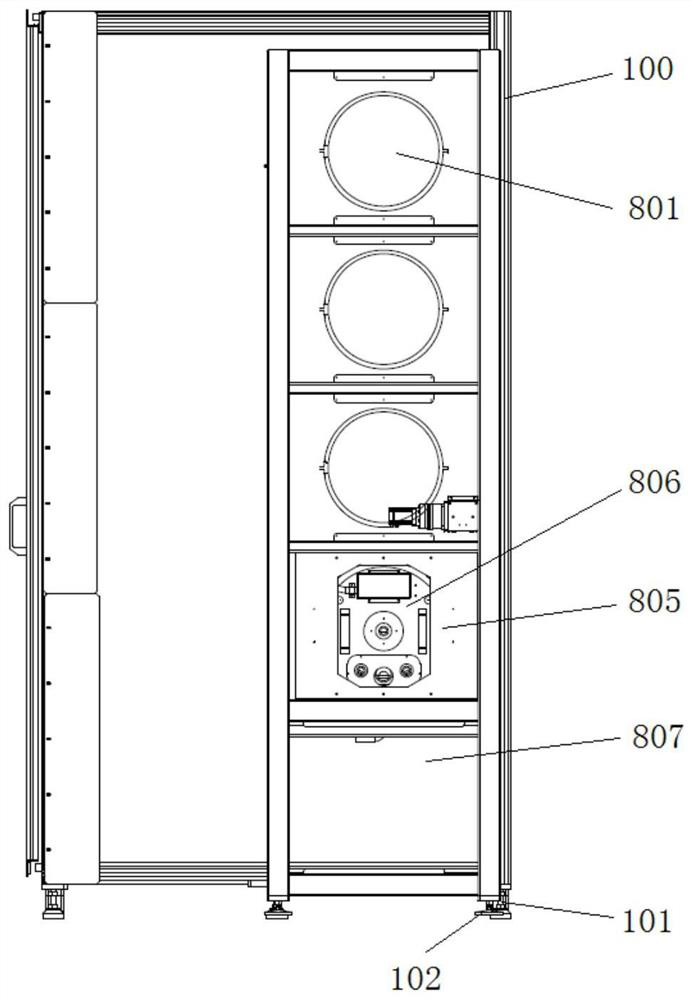

[0047] figure 1 and figure 2 It shows the overall appearance structure of the present invention and the matching structure of a set of reaction furnace and boat moving system. As shown in the figure, the present invention provides a continuous vacuum diffusion furnace, including a feeding part and a reaction furnace part, wherein the feeding part is as figure 1 and 2 As shown in the middle left half, the part of the reactor is as follows figure 1 and 2 As shown in the middle right half, the feeding part includes a feeding frame 100 and a boat moving mechanism. The boat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com