Large-gradient indoor ski resort trail and antiskid making method

A ski resort, high-slope technology, applied in the directions of roads, roads, pavements, etc., can solve problems such as surface concrete cracks, and achieve the effect of reasonable structure, controllable cost, and good anti-slip ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

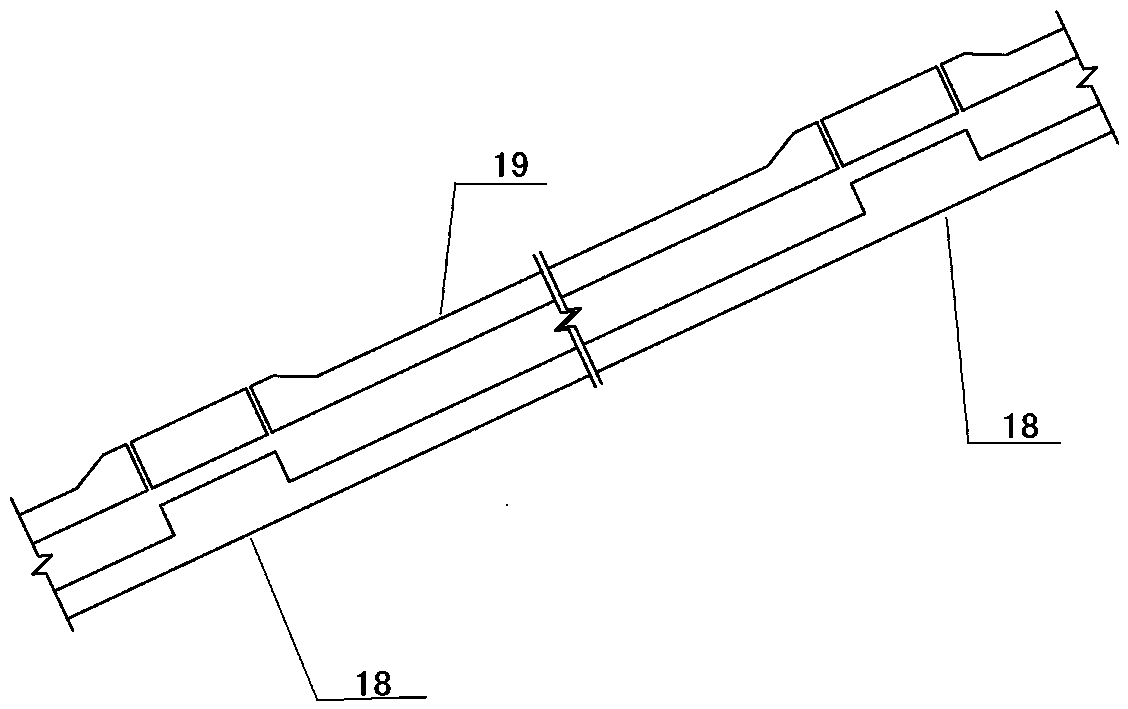

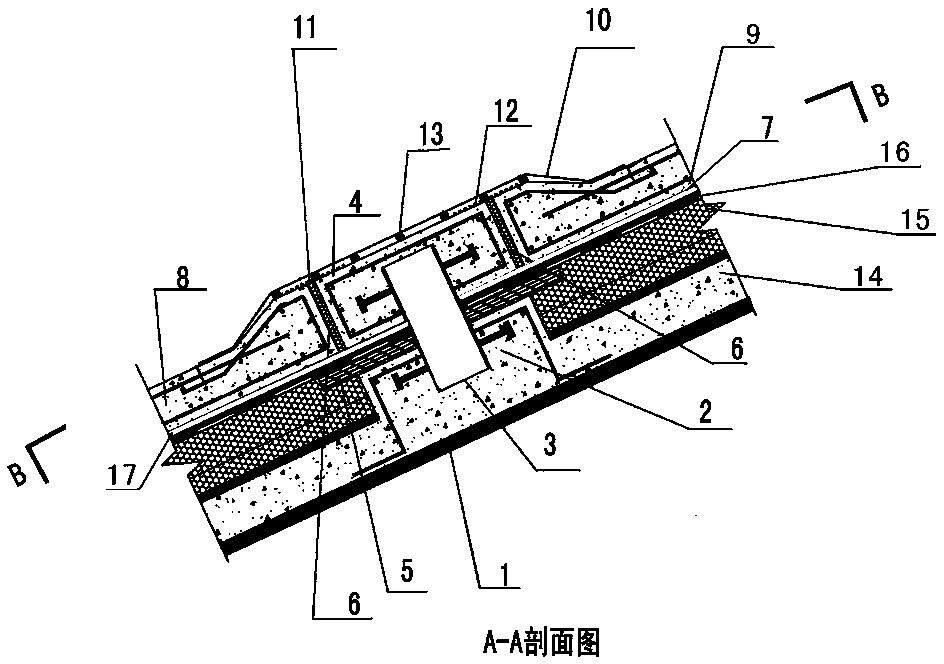

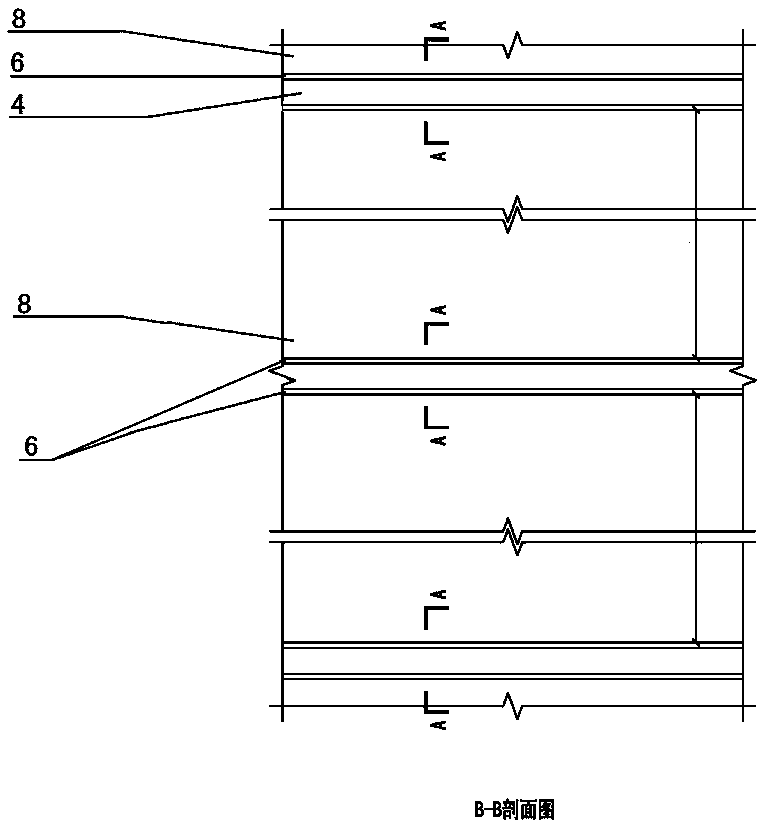

[0038] Such as figure 1 , figure 2 , image 3 As shown, one aspect of the present invention provides a large-slope indoor ski slope. The ski run is arranged on the base floor 1 and is continuously distributed along the base floor 1. The ski run includes several continuously arranged unit ski runs. The unit ski run includes two sections of the first ski run 18 and a second snow run 19 arranged between the two sections of the first snow run 18 . A heat medium circulation pipeline may also be arranged in the base floor 1 .

[0039] The unit snow track is a segmented structure, and the joints of the first snow track 18 and the second snow track 19 are all disconnected and have deformation seams, and fillers 6 (which can be extruded board isolation strips, such as : Ordinary extruded board isolation strip and / or high-strength extruded board isolation strip), the surface of the deformation joint is painted with polyurethane waterproof additional layer 11 for preventing snow or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com