Karst landform based hydropower station diversion tunnel plugging construction method

A construction method and technology of diversion tunnels, applied in hydropower stations, hydroelectric power generation, water conservancy projects, etc., can solve the problems of narrow construction surface and difficult sealing, and achieve high safety, low construction cost and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

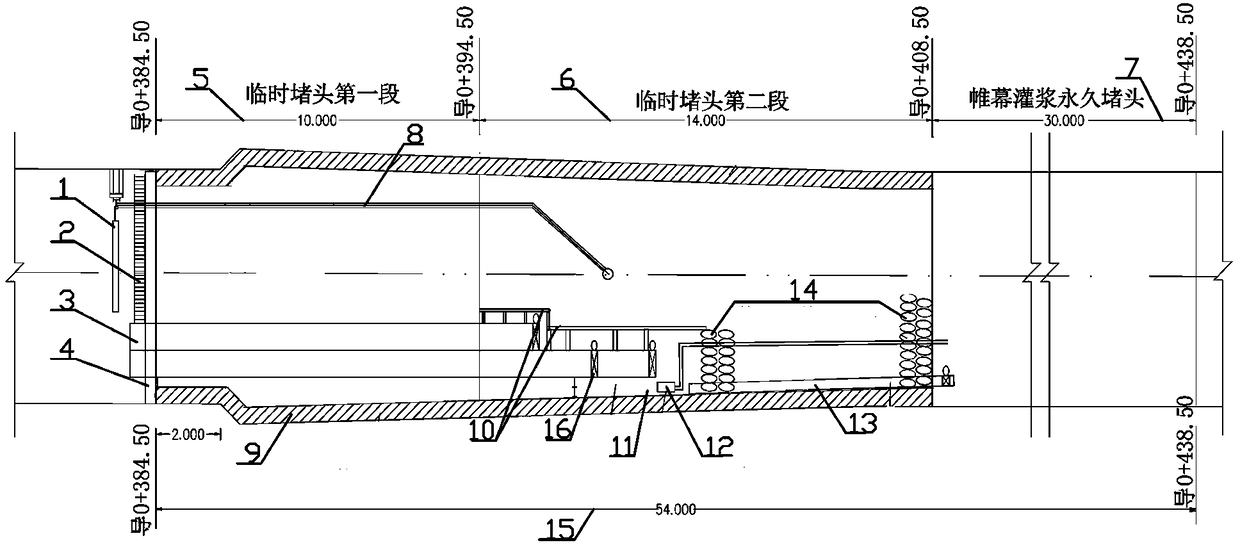

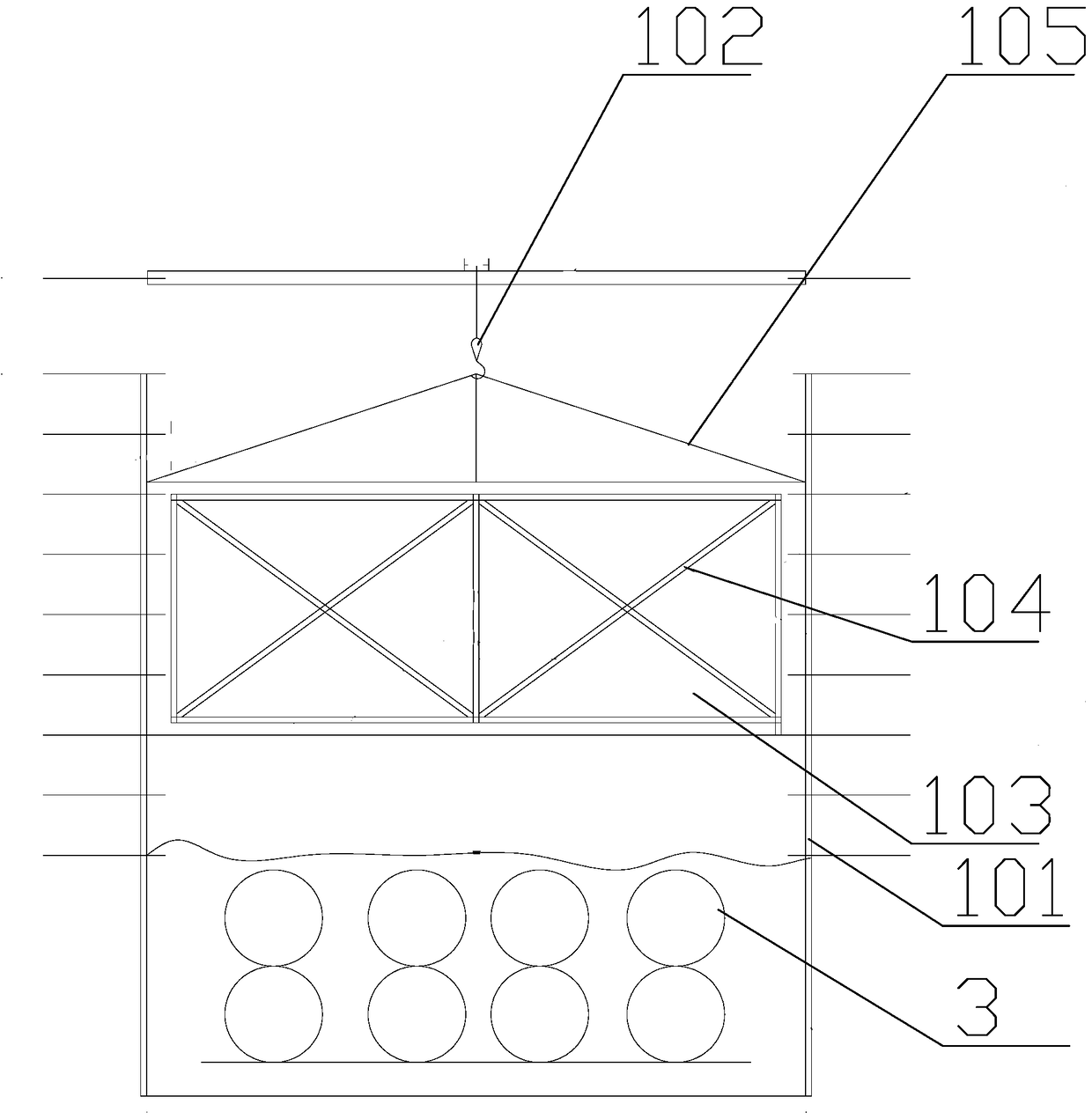

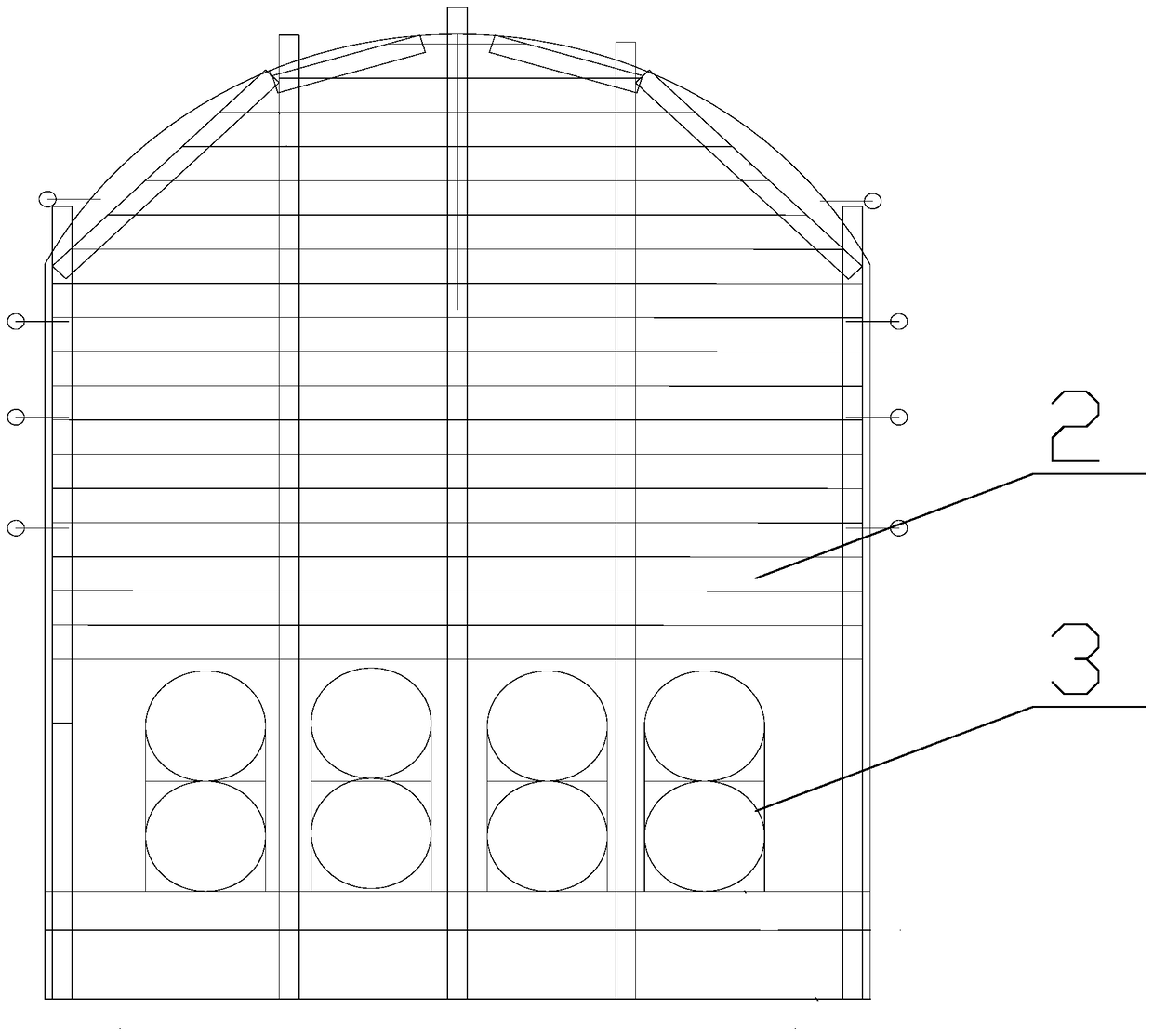

[0062] see Figure 1-3 , a construction method for plugging diversion tunnels of hydropower stations based on karst landforms, which includes the following steps:

[0063] S1: Design diversion tunnel plugging scheme

[0064] Facing the severe situation of prominent safety hazards in diversion tunnel closure, short construction period, and difficult construction, after in-depth analysis of the overall stability of the diversion tunnel and the change law of flow and velocity in the tunnel, the "clogging in the tunnel is the main, Based on the principle of supplementary anti-seepage outside the tunnel, it was decided to adopt the plugging scheme of temporary plug plus permanent plug. Temporary plug is the most critical part of the entire plugging work, and the construction plan of temporary plug is focused on. The temporary plug section is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com