A special-shaped prefabricated prestressed wall connection structure and assembly method

A connection structure and prestressing technology, applied to walls, building components, building structures, etc., to achieve the effect of increasing construction speed, reducing production costs, and improving mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

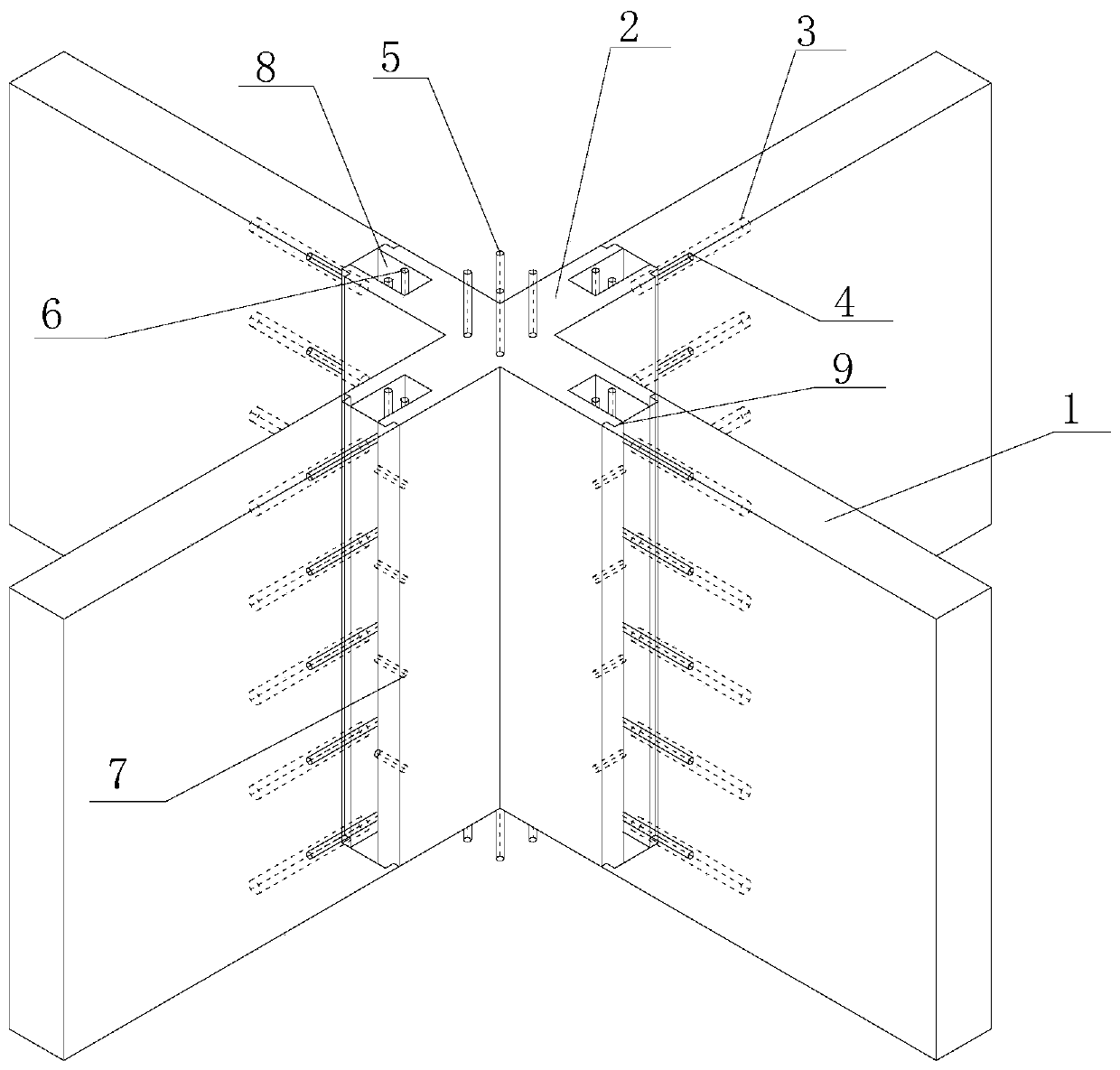

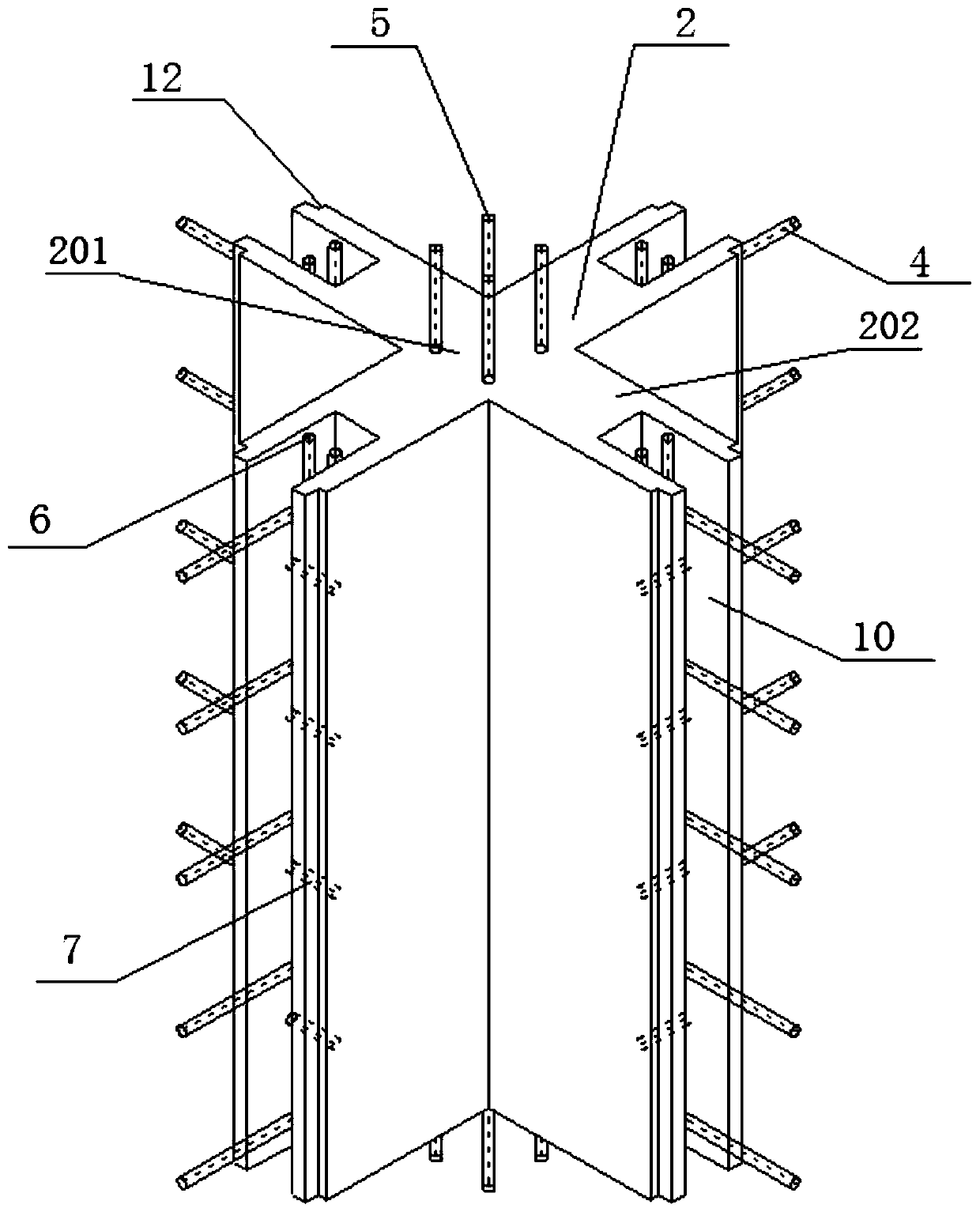

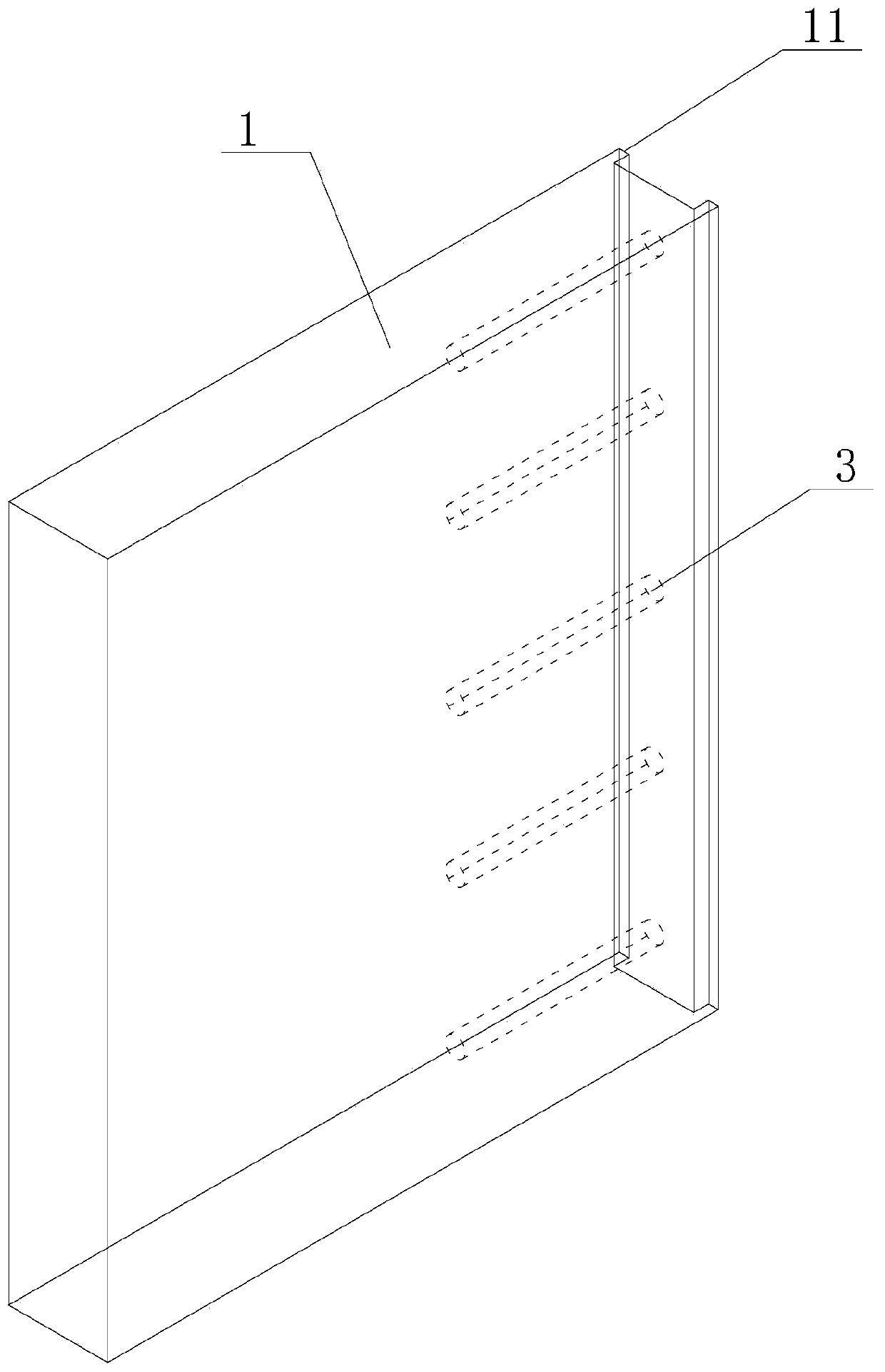

[0036] As shown in the figure, the present invention discloses a special-shaped prefabricated prestressed wall connection structure, including a shear wall panel 1 and a prestressed wall 2, and the prestressed wall 2 includes a base body 201 and is distributed around the base body 201 The connecting body 202, the connecting body 202 is provided with a longitudinal groove 10, and the longitudinal groove 10 passes through the top surface, the bottom surface of the connecting body 202 and the side away from the base body 201; the shear wall panel One side of 1 is connected to the longitudinal groove 10, so that the longitudinal groove 10 forms a longitudinal well 8; the prestressed steel bars 5 penetrating the top and bottom surfaces of the matrix 201 are distributed in the matrix 201, Transverse shear reinforcement bars 7 crossing the longitudinal groove 10 are pre-embedded in the longitudinal groove 10, and a pre-embedded steel bar 4 is arranged between the shear wall panel 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com