Swing cylinder drive structure for industrial carrying manipulators

A transmission structure and swing cylinder technology, applied in the field of manipulators, can solve problems such as high sealing requirements, difficult processing, and complex structures, and achieve the effects of good sealing, small size, and simplified manipulator structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

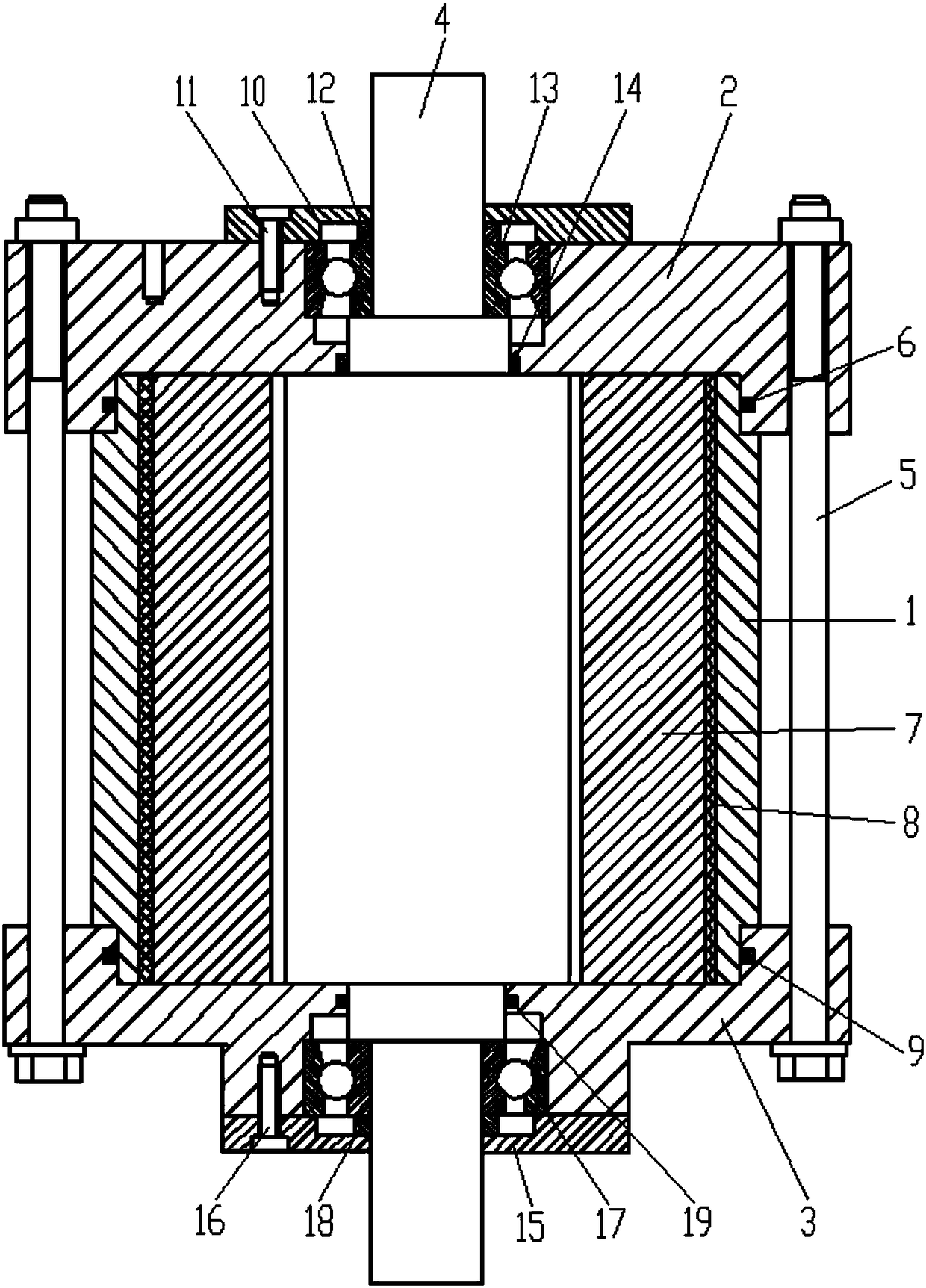

[0013] Attached below figure 1 Embodiments of the present invention are described.

[0014] Swing cylinder transmission structure for industrial handling manipulator, such as figure 1 As shown, it includes a swing cylinder cylinder 1, the front end of the swing cylinder cylinder 1 is sealed and connected with a swing cylinder front end cover 2, and a front sealing ring I6 is provided at the contact between the swing cylinder front end cover 2 and the front end of the swing cylinder cylinder 1, The rear end of the swing cylinder barrel 1 is sealed and connected with a swing cylinder rear end cover 3 , and a rear sealing ring I9 is provided at the contact between the swing cylinder rear end cover 3 and the rear end of the swing cylinder barrel 1 .

[0015] An output shaft 4 is supported in the cylinder barrel 1 of the swing cylinder, and the front end of the output shaft 4 is supported in the front end cover 2 of the swing cylinder through a front bearing 13 and extends outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com