A molten salt reactor core

A molten salt reactor and core technology, applied in the field of molten salt reactor core, can solve the problems of affecting heat transfer and neutron characteristics, breakage of corner fracture components, low fuel utilization value, etc., so as to reduce the irradiation fluence rate , reduce the deformation stress, and facilitate the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

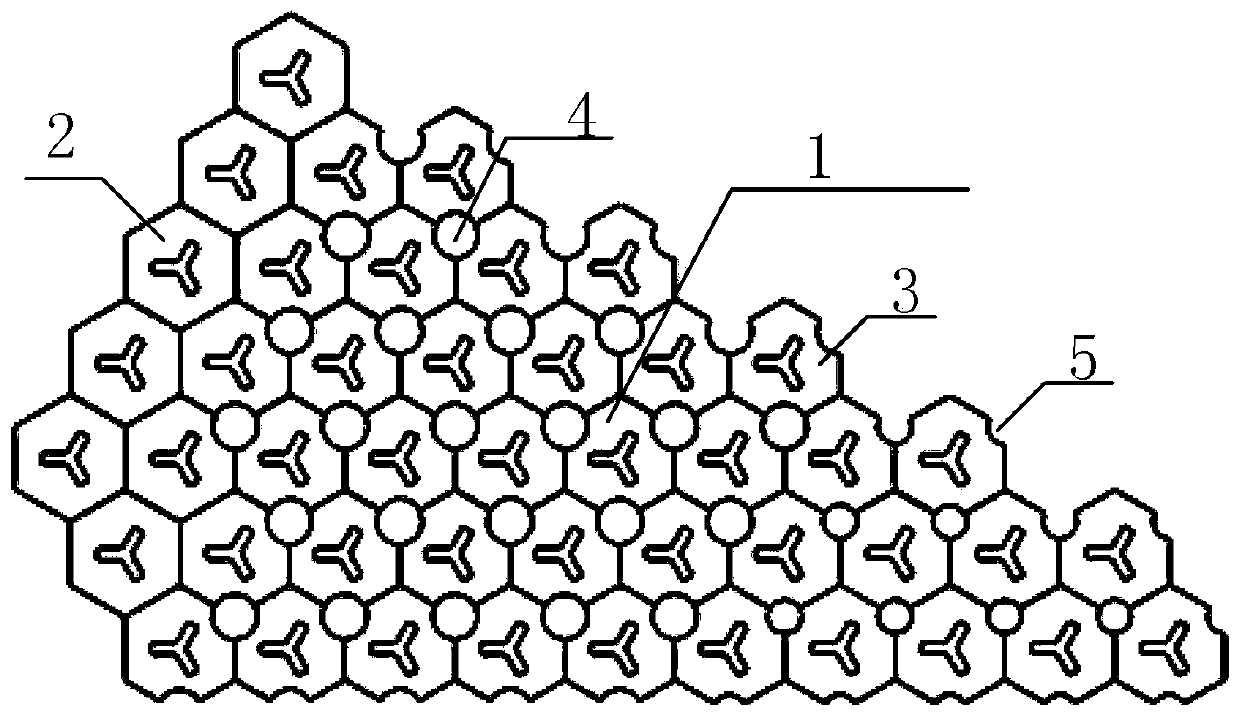

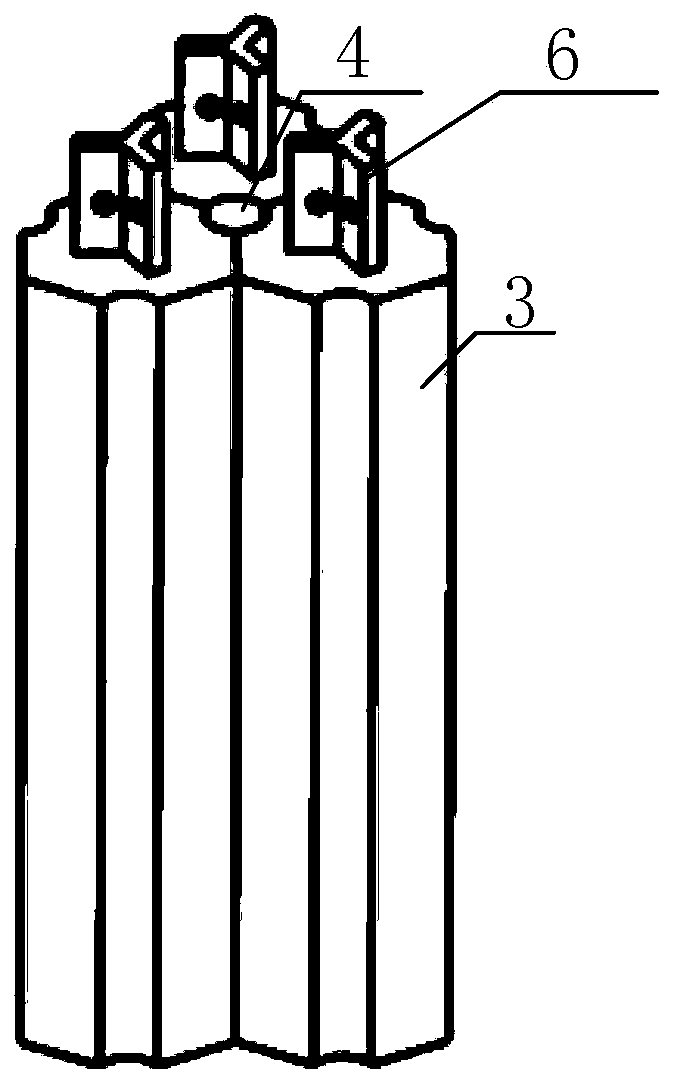

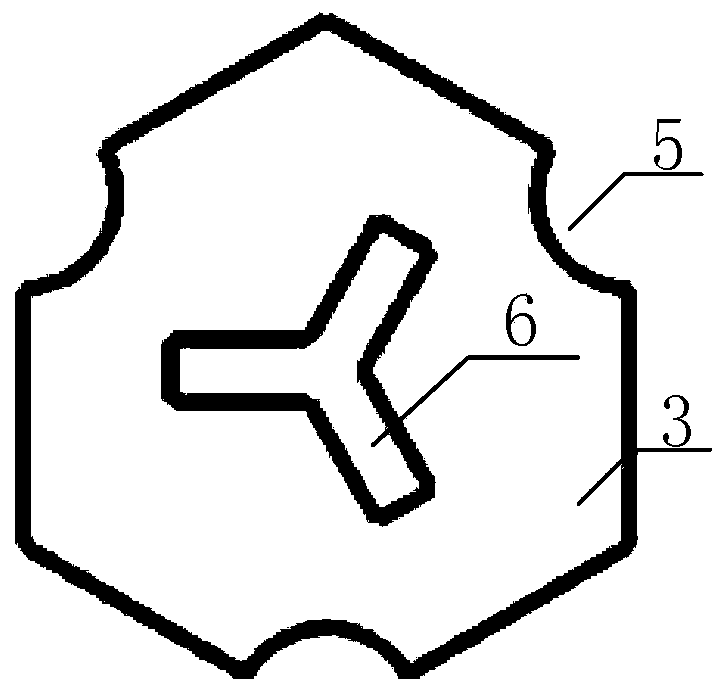

[0076] The top view of the molten salt reactor core in this embodiment is shown in figure 1 , which includes an active area 1 and a reflective layer 2, the reflective layer 2 covers the active area 1, and the active area 1 is assembled from an array of fuel assemblies 3;

[0077] Wherein, the fuel assembly 3 is a chamfered regular hexagonal prism, the chamfered positions of the three fuel assemblies 3 are opposite, and the gap 5 forms a molten salt channel 4; the volume of the molten salt channel 4 accounts for 5% of the volume of the active area 1; the active area 1 is divided into a central area and an edge area, the volume ratio of the central area to the edge area is 1 / 14, and the volume of the single molten salt channel 4 in the central area accounts for 40% of the volume of the single molten salt channel 4 in the edge area.

[0078] In this embodiment, the assembly of the reflective layer 2 is used in conjunction with the fuel assembly 3 in the active area 1, and the ass...

Embodiment 2

[0097] The assembly of the fuel assembly 3 and the reflection layer 2 of the molten salt reactor core of this embodiment is a regular quadrangular prism, wherein the structure of the fuel assembly 3 is as follows Figure 17 shown. The volume of the molten salt channel 4 accounts for 6% of the volume of the active area 1 . The side edges of the regular quadrangular prism are cut by the outer arc surface, and the length of the bottom surface of the cut cuboid is 2 cm. The distance across sides of the cuboid is 20cm, the height of a single cuboid is 1m, and there are 5 layers in total, and the thickness of the reflective layer 2 is 30cm. The arrangement, engagement and fixation of the components of the fuel assembly 3 and the reflective layer 2 in this embodiment are similar to those in the first embodiment.

Embodiment 3

[0099] The assembly of the fuel assembly 3 and the reflection layer 2 of the molten salt reactor core of this embodiment is a regular quadrangular prism, wherein the structure of the fuel assembly 3 is as follows Figure 18 As shown, the side edges of the cuboid are cut by the inner arc surface, and the side length of the bottom surface of the cut regular prism is 5.5 cm. The volume of the molten salt channel 4 accounts for 6% of the volume of the active area 1 . The distance across sides of the regular quadrangular prism is 20cm, the height of a single cuboid is 1m, and there are 5 layers in total, and the thickness of the reflective layer 2 is 30cm. The arrangement, engagement and fixation of the components of the fuel assembly 3 and the reflective layer 2 in this embodiment are similar to those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com