Fluid-cooled heat sink and embedded fluid-cooled heat sink type lead-acid storage battery

A lead-acid battery, liquid cooling technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve the problems of battery life reduction, voltage attenuation, high cost, improve energy density, improve vibration resistance sex, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further. The embodiments described with reference to the drawings are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

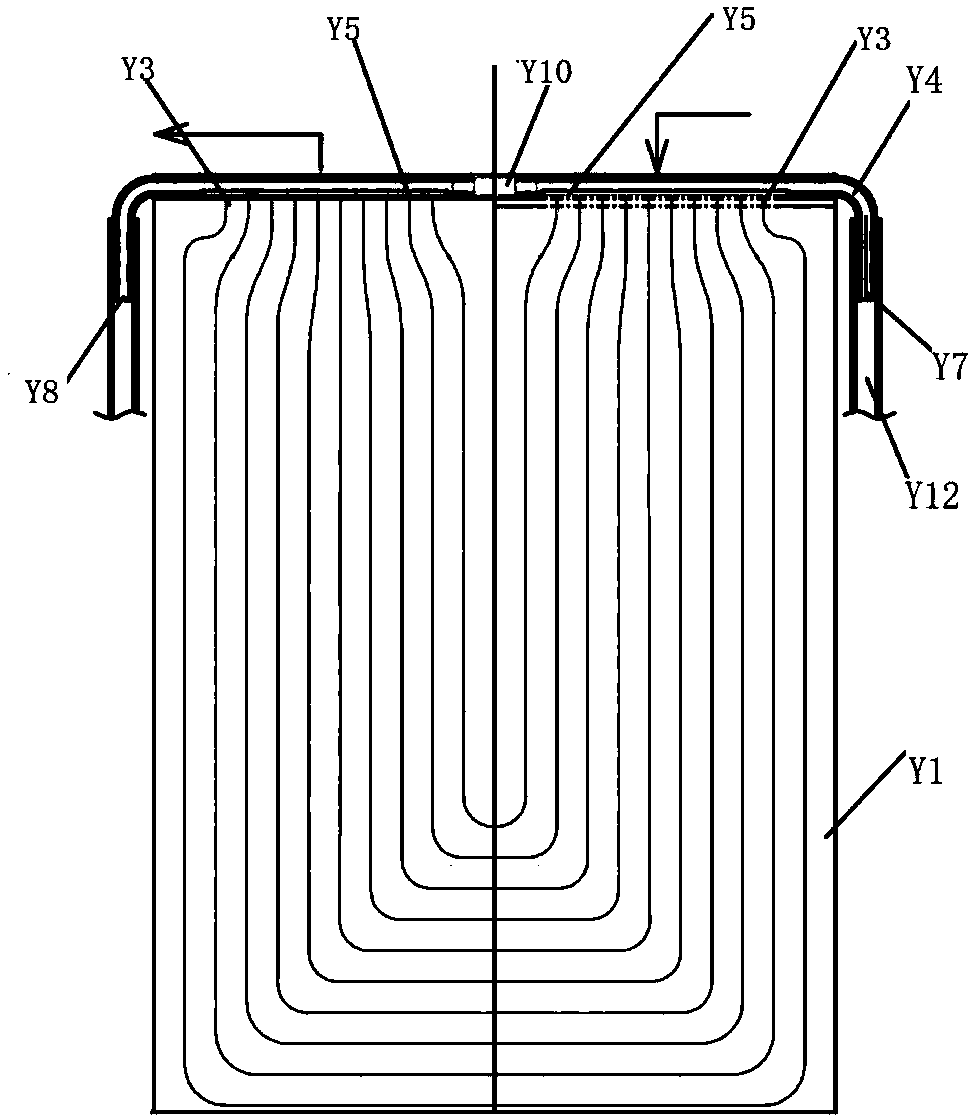

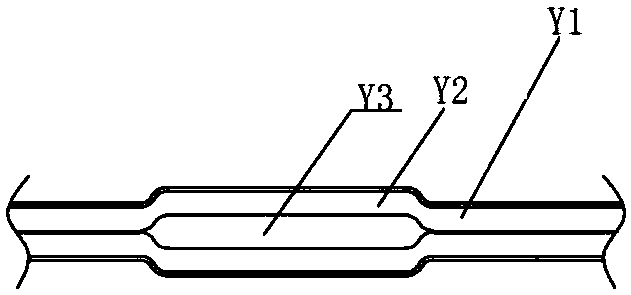

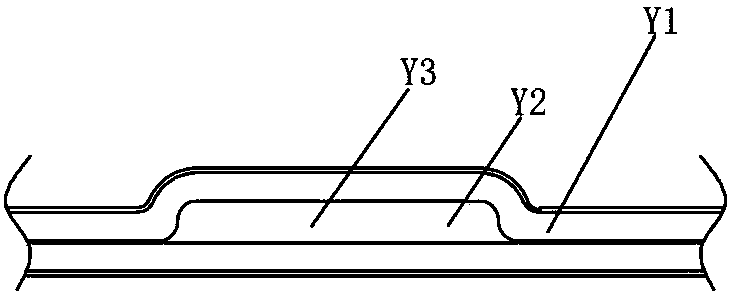

[0038] Such as figure 1 , figure 2 with image 3As shown, in this embodiment, a plurality of through grooves Y2 are punched out by stamping the aluminum sheet Y1. The end and the tail end are respectively arranged at the two ends of the Y1 side of the aluminum sheet, and a semicircle shape is punched out on the Y1 side of the aluminum sheet, and the concave-convex direction of the semicircle is consistent with the concave-convex direction of the through groove Y2; the liquid of this embodiment The cooling fin is formed by bonding two pieces of aluminum sheet Y1 with the above-mentioned structure. Two through grooves Y2 are arranged oppositely and their inner surfaces are gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com