Fine dried noodle cutting device

A noodle cutting and noodle technology, applied in dough forming and cutting equipment, dough processing, baking, etc., can solve the problems of high defective rate of dried noodles, low work efficiency, single function, etc., to ensure the consistency of taste and shorten the work The effect of improving time and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

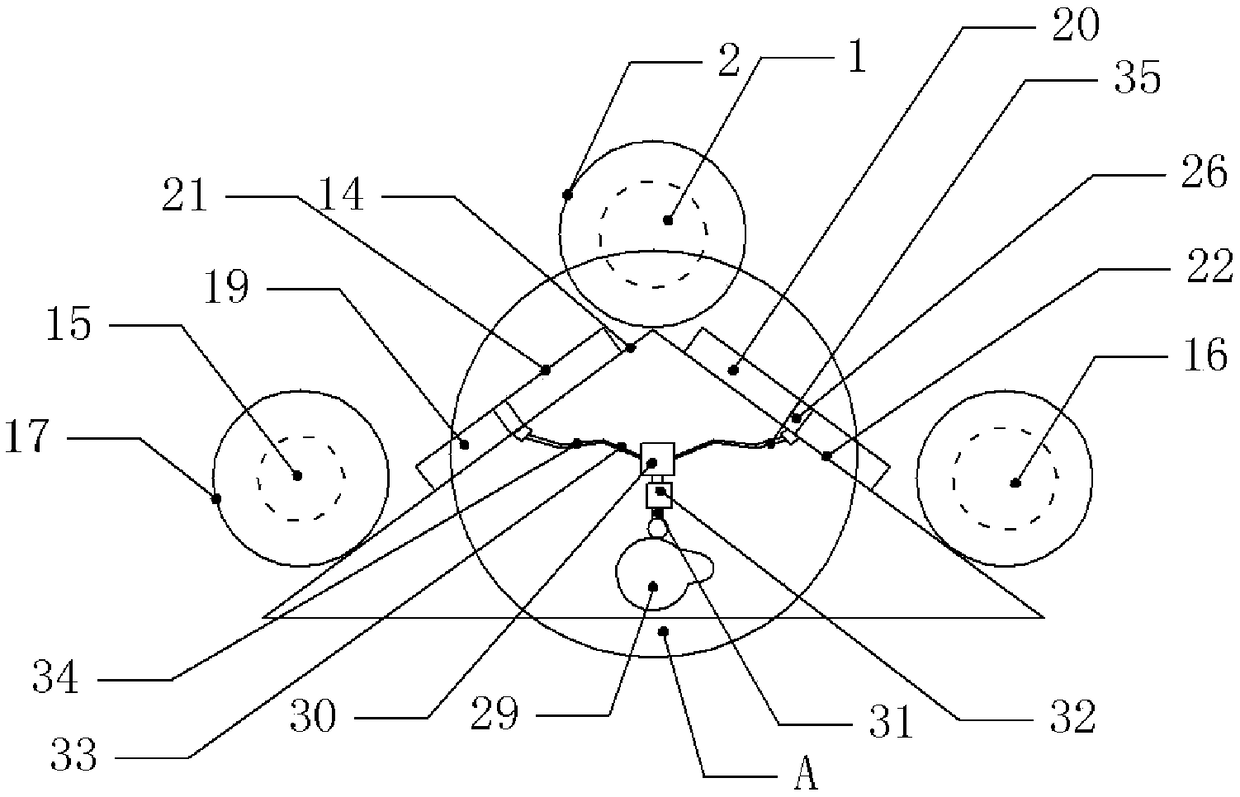

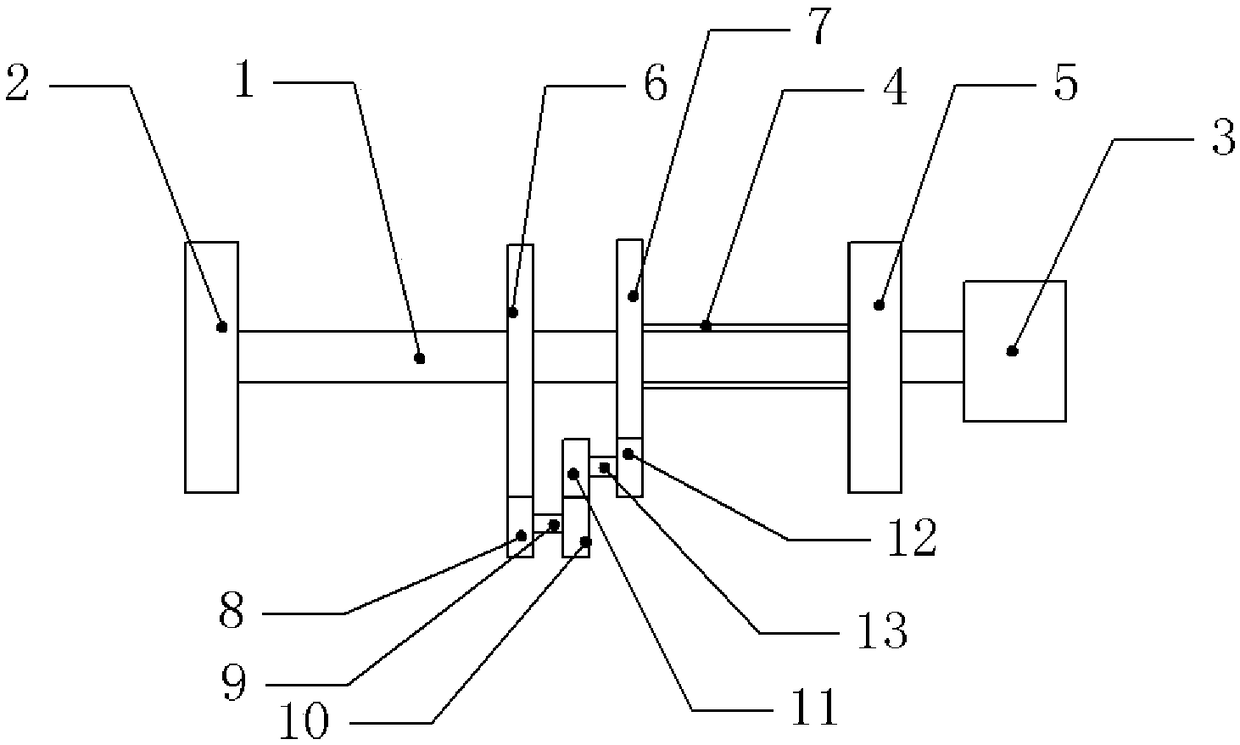

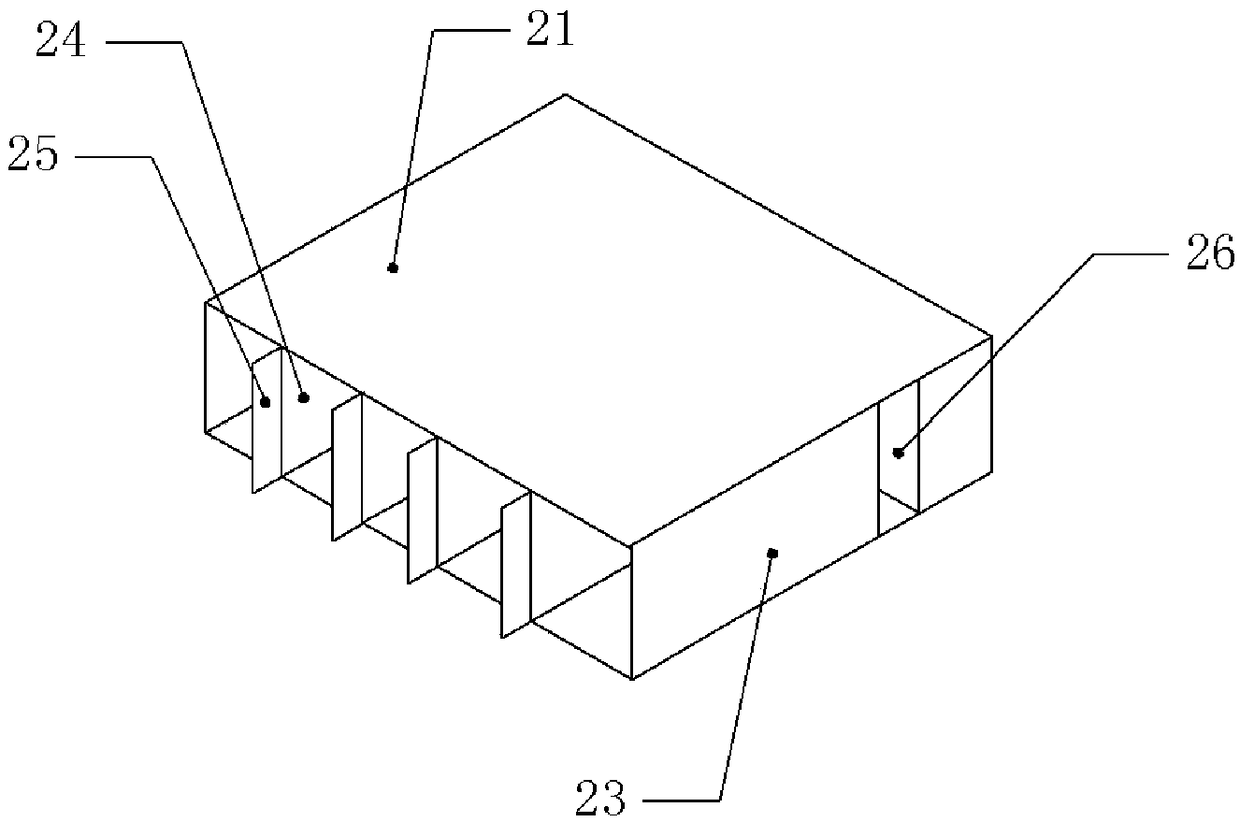

[0024] The reference signs in the accompanying drawings of the description include: rolling roll 1, first baffle plate 2, first motor 3, reverse roller 4, second baffle plate 5, forward gear 6, reverse gear 7, first gear 8. First fixed shaft 9, second gear 10, third gear 11, fourth gear 12, second fixed shaft 13, cutting table 14, forward feed roller 15, reverse feed roller 16, blocking plate 17 , pressing roller 18, reverse cutting part 19, forward cutting part 20, upper plate 21, lower plate 22, side plate 23, partition 24, cutting knife 25, knife feed slot 26, upper channel 27, lower channel 28 , Cam 29, push block 30, connecting rod 31, sleeve 32, push rod 33, pole 34, feed 35.

[0025] Example figure 1 and figure 2 Shown: a noodle cutting device, comprising a frame and a noodle roll 1, one end of the noodle roll 1 is threadedly connected with a first baffle 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com