Door plank polishing machine with automatic dust removing function

A technology of automatic dust removal and grinding machine, applied in the direction of grinding frame, cleaning method using tools, machine tool suitable for grinding the edge of workpiece, etc. To achieve the effect of reducing the degree of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

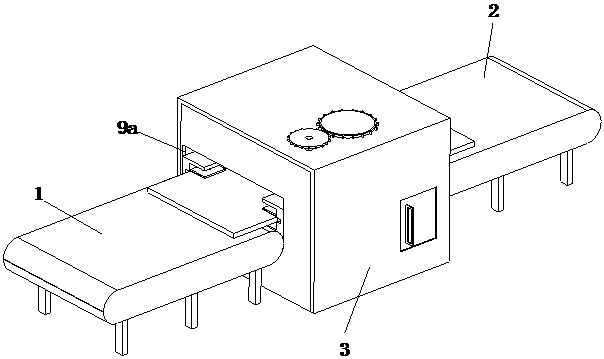

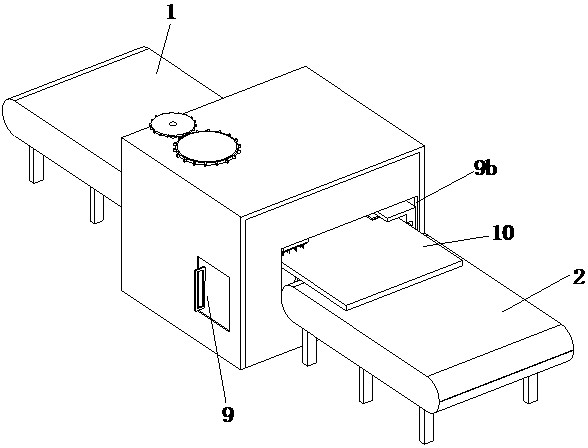

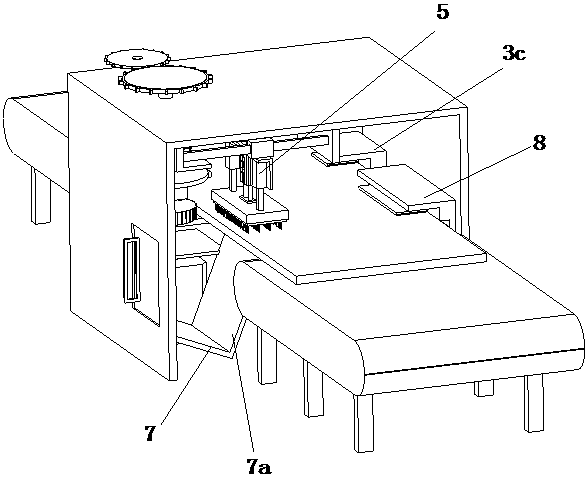

[0025] refer to Figure 1 to Figure 8 The shown door panel grinder with automatic dust removal function includes a feed conveyor belt 1 and a discharge conveyor belt 2, and also includes a dust isolation bin 3, two first positioning devices 3c located symmetrically in the dust isolation bin 3, and a The dust removal device on the top wall of the dust-proof bin 3, the dust-proof bin 3 is erected between the feed conveyor belt 1 and the discharge conveyor belt 2, and the front side of the dust-proof bin 3 and the back side facing the discharge conveyor belt 2 are respectively equipped with The first notch 9a and the second notch 9b through which the door panel 10 can pass, one side in the dust-proof bin 3 is provided with a vertical grinding motor 3a, and the main shaft of the grinding motor 3a is sleeved for grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com