Device for manufacturing easily demolded wood-plastic formwork for building

A technology for wood-plastic formwork and construction, which is applied in the field of production equipment for building formwork, and can solve problems such as not meeting the requirements of building construction, increasing the workload of cleaning formwork, and rough surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

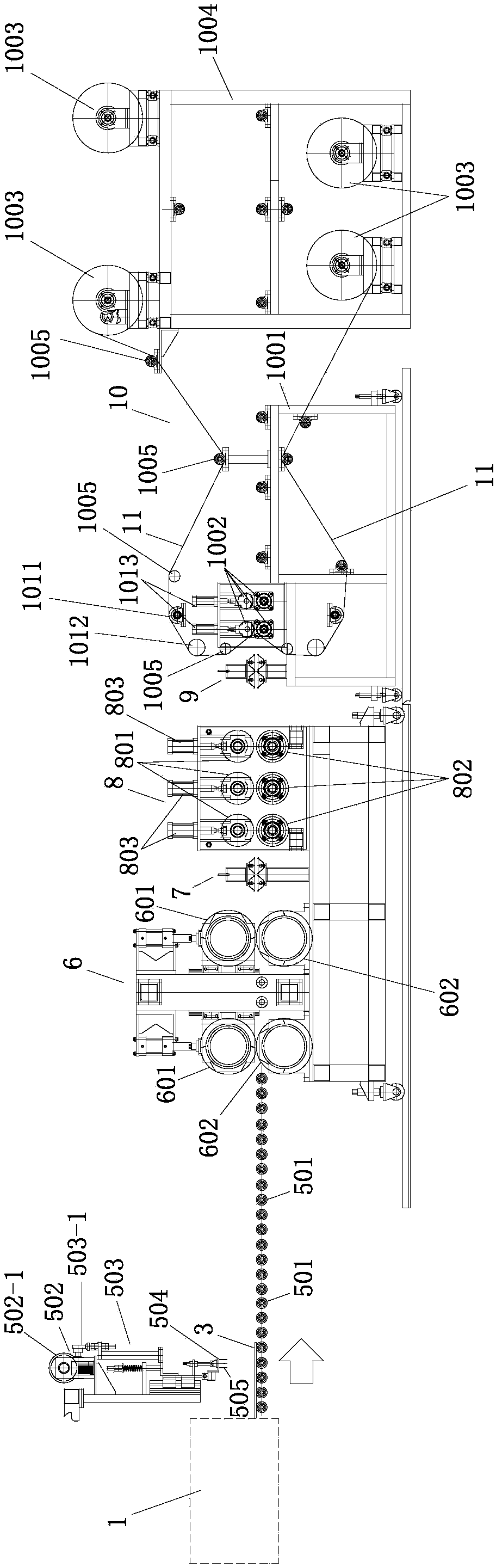

[0038] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

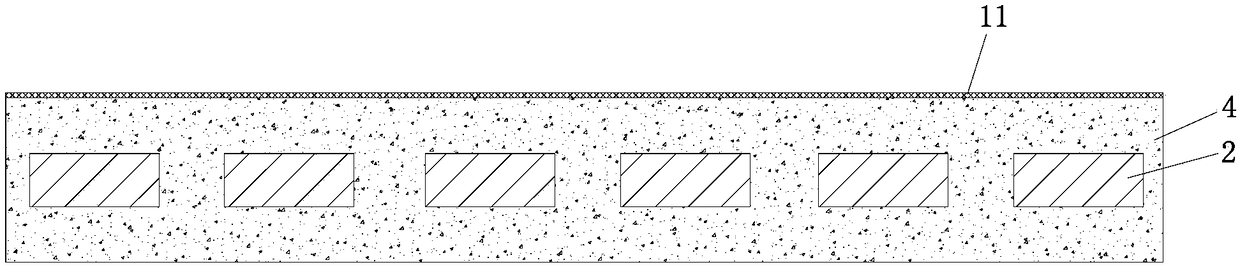

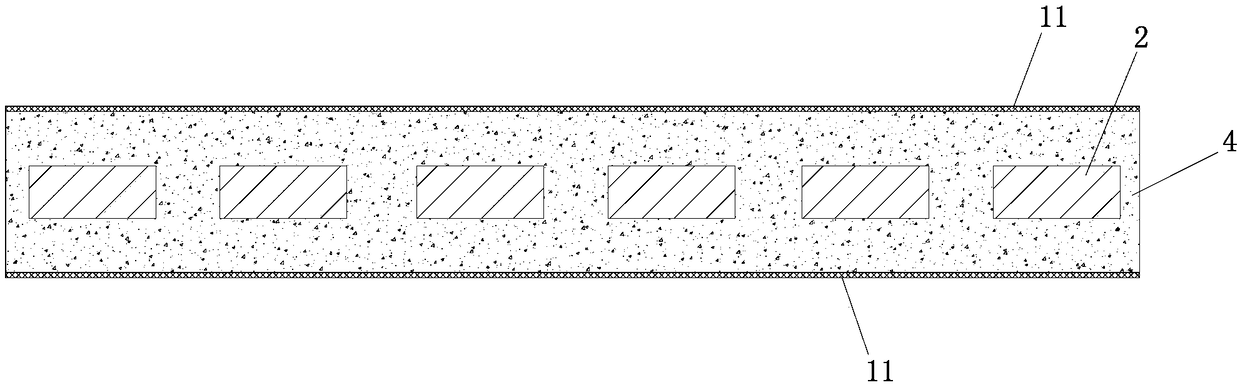

[0039] Such as Figure 1 to Figure 11 Shown: a device for manufacturing wood-plastic formwork for construction that is easy to release from the mold, including a wood-plastic blank plate forming mechanism 1, through the wood-plastic blank plate forming mechanism 1, wooden strips 2 are integrated into a plastic body 4 to form a wood-plastic blank The plate 3 is characterized in that it also includes an acupuncture exhaust mechanism 5, a calendering and leveling four-roller 6, a shallow heating mechanism 7, a finishing and calendering mechanism 8, and a shallow rapid heating mechanism before film application. 9 and film feeding and film sticking mechanism 10;

[0040] The acupuncture exhaust mechanism 5 is arranged between the slab outlet of the wood-plastic blank sheet forming mechanism 1 and the calendering and leveling four-roller 6;

[0041] The acupuncture ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com