Method for degrading antibiotic ciprofloxacin hydrochloride

A technology of ciprofloxacin hydrochloride and antibiotics, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high toxicity and complex components of antibiotic wastewater , large emissions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

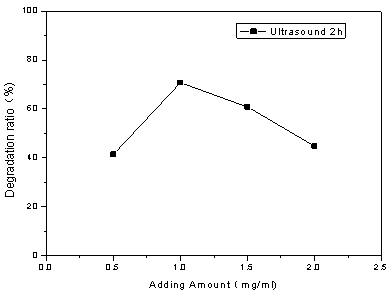

[0025] Embodiment 1: by figure 2 It can be seen that in CaWO 4 Under the presence and ultrasonic conditions, the degradation rate of ciprofloxacin hydrochloride gradually increased with the addition of 0.5 to 1, and then gradually decreased with the addition of 1 to 2, indicating that CaWO 4 Catalyzed ultrasonic degradation of ciprofloxacin hydrochloride and catalyst is the best when the ratio is 1:1.

Embodiment 2

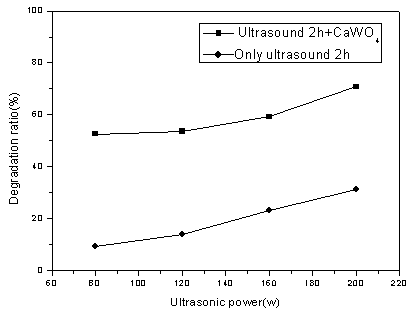

[0026] Example 2: Change the ultrasonic power to study the effect of degrading ciprofloxacin hydrochloride, in the experiment, CaWO 4 The addition amount of ciprofloxacin hydrochloride was 1.0 g / L, the ultrasonic irradiation time was 120 min, the pH of the dye solution was 6, the concentration of ciprofloxacin hydrochloride was 10 mg / L, and the output power of the ultrasonic device was set in the range of 80-200 W . Depend on image 3 It can be seen that when the ultrasonic power gradually increased, the degradation rate of ciprofloxacin hydrochloride also increased significantly.

Embodiment 3

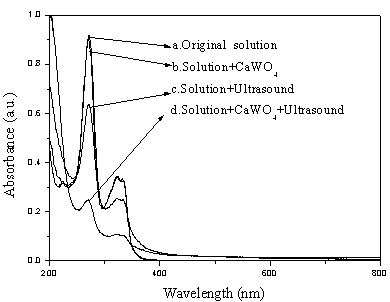

[0027] Example 3: CaWO 4 The experiment on the degradation rate of ciprofloxacin hydrochloride is carried out at the addition of 1 g / L, the ultrasonic irradiation time is 120min, the concentration of ciprofloxacin hydrochloride is 10mg / L, the pH of the solution is 6, the power of the ultrasonic device for 200W. Take 80 mL of 10 mg / L ciprofloxacin hydrochloride solution, add an accurately weighed certain amount of 1 g / L nano-CaWO 4 powder, stirred magnetically for 30 min in the dark. After the suspension was irradiated by ultrasound for 2 hours, the sample was centrifuged and the supernatant was taken. The degradation rate of ciprofloxacin hydrochloride was 70.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com