Device and method capable of quickly and accurately laser cutting three-dimensional chambered-surface glass

A technology of laser cutting and curved glass, applied in the field of optics, can solve problems such as low efficiency, deviation of processing size, pollution of the environment, etc., and achieve the effect of improving efficiency and reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

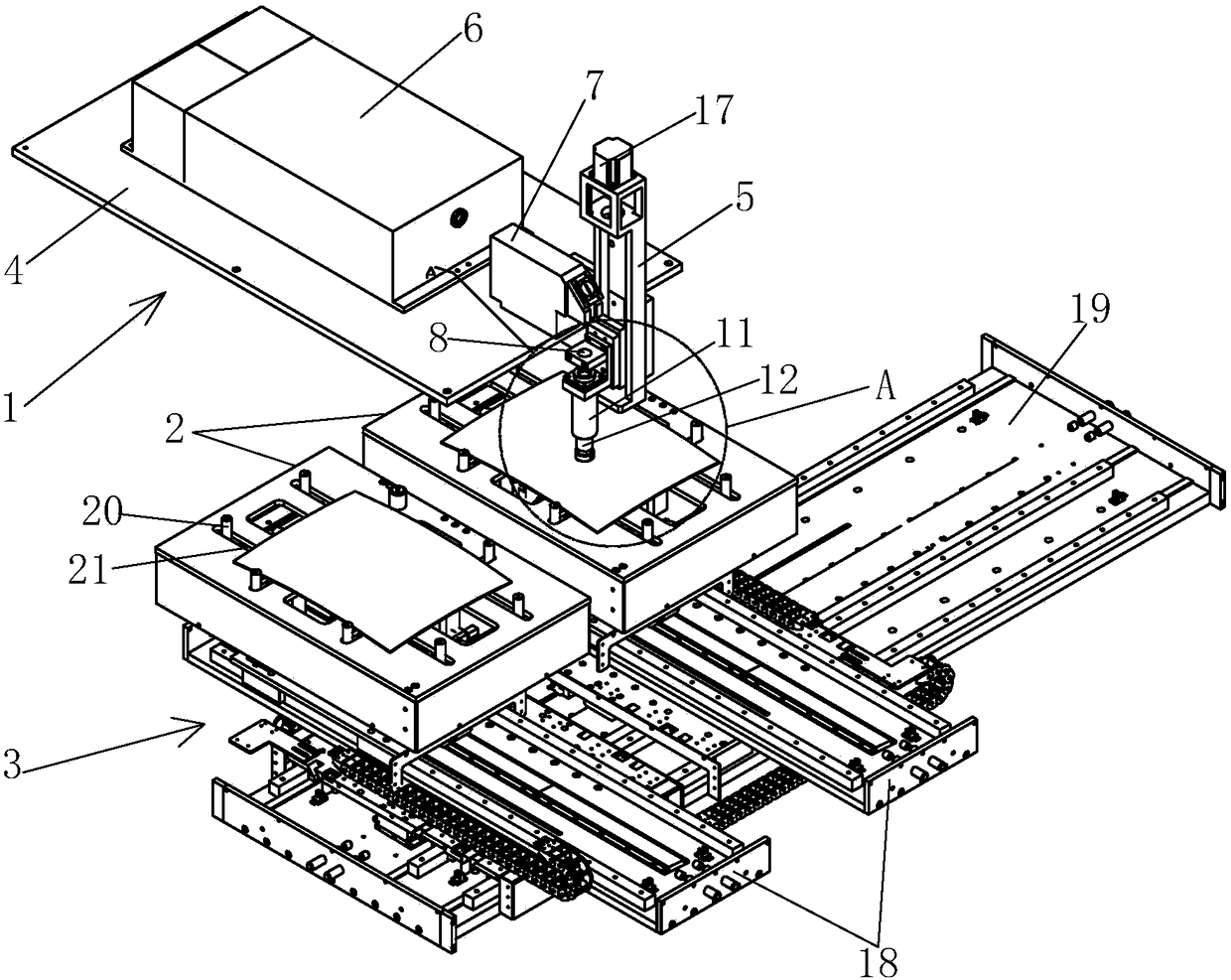

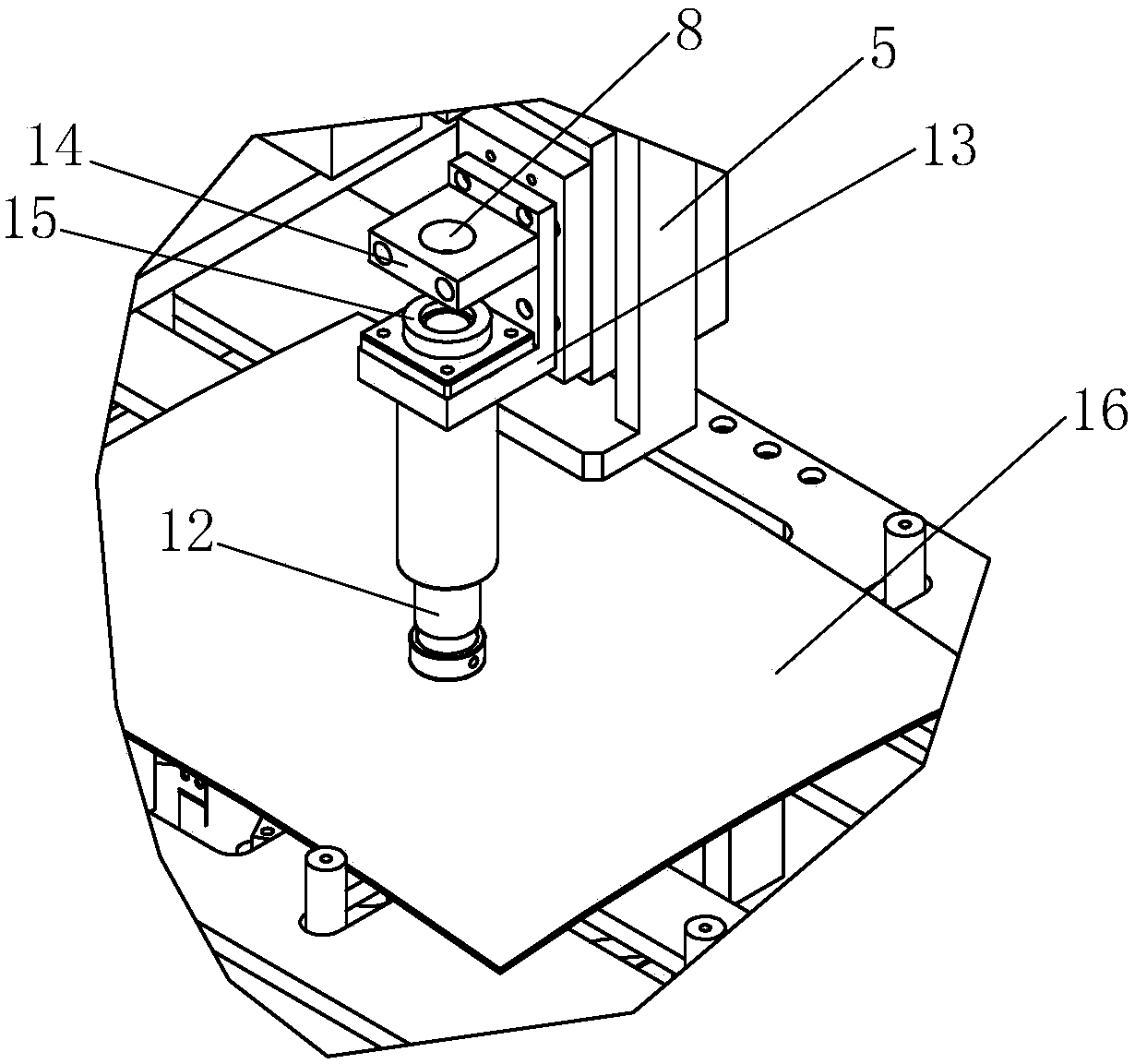

[0029] Embodiment: a device for cutting three-dimensional curved glass quickly and accurately, such as Figure 1-5 As shown, it includes a bracket 1, a placement platform 2 for placing three-dimensional curved glass, a mobile positioning mechanism 3 and a high-speed laser system, wherein the placement platform 2 is arranged on the mobile positioning mechanism 3 and is placed on the mobile positioning mechanism. 3. Move along the X-axis or Y-axis direction under the action of the high-speed laser system. The high-speed laser system is set on the support 1 and the high-speed laser system is located above the placement platform 2; the support includes a horizontal support 4 and a vertical Z-direction support 5.

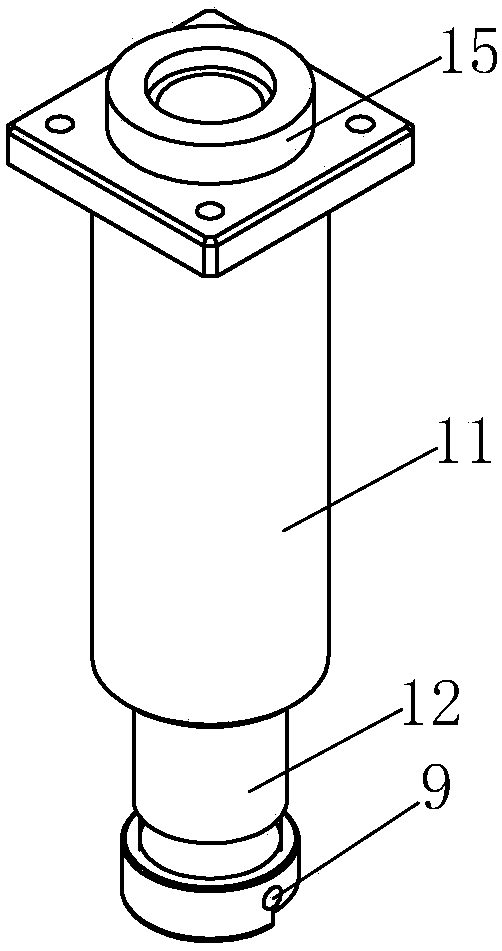

[0030] The high-speed laser system includes a high-speed laser 6, a mirror 7 and a wave plate 8, and a vertically arranged linear bearing 11, a hollow optical shaft 12, a contact head 9, and a focusing mirror 10; the hollow optical shaft 12 and the linear bearing 11 sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com