Bismuth sodium titanate based dielectric film with high energy storage density and its preparation method and application

A high energy storage density, bismuth sodium titanate-based technology, applied to fixed capacitor dielectrics, circuits, capacitors, etc., to achieve good temperature stability, high energy storage density, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

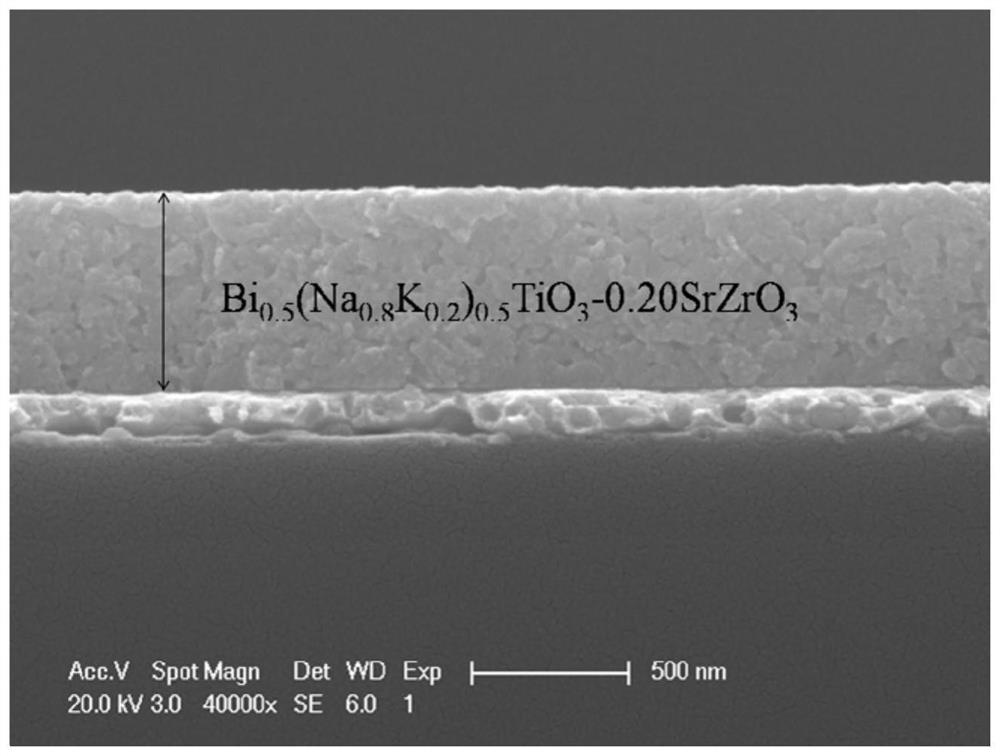

Image

Examples

Embodiment 1

[0043] (1) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , x = 0.05 stoichiometric ratio Weigh sodium acetate, potassium acetate, bismuth nitrate, strontium acetate dissolved in acetic acid, stirred and heated to boiling for 20 to 30 minutes to prepare solution A.

[0044] (2) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , x = 0.05 stoichiometric ratio Weigh tetrabutyl titanate, and weigh a certain amount of acetylacetone, dissolve tetrabutyl titanate in ethylene glycol methyl ether, stir and heat to 50°C, stir for 20-30 minutes Solution B was prepared.

[0045] (3) Mix precursor solution A and precursor solution B, use acetic acid to adjust the concentration of the solution, use ammonia water to adjust the pH of the solution, and stir at 50°C for 300 minutes to prepare Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 precursor solution.

[0046] (4) Pt / Ti / SiO 2 / Si substrate cut to a s...

Embodiment 2

[0053] (1) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , x = 0.10 stoichiometric ratio Weigh sodium acetate, potassium acetate, bismuth nitrate, strontium acetate dissolved in acetic acid, stirred and heated to boiling for 20 to 30 minutes to prepare solution A.

[0054] (2) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , The stoichiometric ratio of x=0.10 Weigh tetrabutyl titanate, and weigh a certain amount of acetylacetone, dissolve tetrabutyl titanate in ethylene glycol methyl ether, stir and heat to 50°C, stir for 20-30 minutes Solution B was prepared.

[0055] (3) Mix precursor solution A and precursor solution B, use acetic acid to adjust the concentration of the solution, use ammonia water to adjust the pH of the solution, and stir at 50°C for 300 minutes to prepare Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 precursor solution.

[0056] (4) Pt / Ti / SiO 2 / Si substrate cut t...

Embodiment 3

[0063] (1) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , x = 0.15 stoichiometric ratio Weigh sodium acetate, potassium acetate, bismuth nitrate, strontium acetate dissolved in acetic acid, stirred and heated to boiling for 20 to 30 minutes to prepare solution A.

[0064] (2) According to the general chemical formula Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 , The stoichiometric ratio of x=0.15 Weigh tetrabutyl titanate, and weigh a certain amount of acetylacetone, dissolve tetrabutyl titanate in ethylene glycol methyl ether, stir and heat to 50°C, stir for 20-30 minutes Solution B was prepared.

[0065] (3) Mix precursor solution A and precursor solution B, use acetic acid to adjust the concentration of the solution, use ammonia water to adjust the pH of the solution, and stir at 50°C for 300 minutes to prepare Bi 0.5 (Na 0.8 K 0.2 ) 0.5 TiO 3 -xSrZrO 3 precursor solution.

[0066] (4) Pt / Ti / SiO 2 / Si substrate cut t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

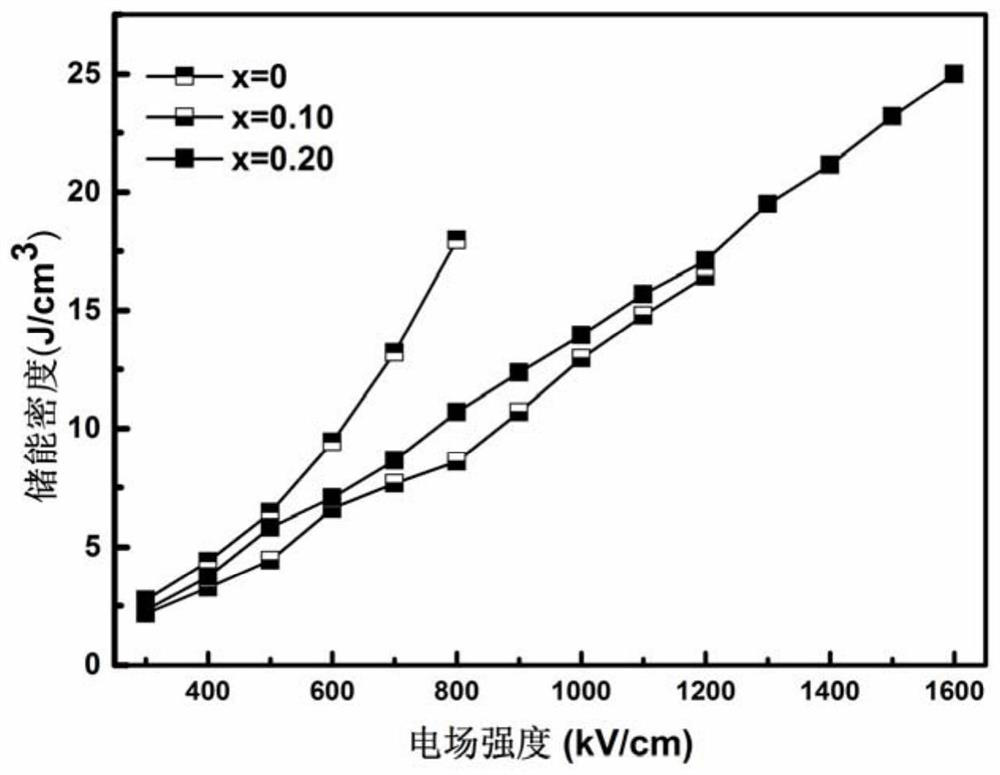

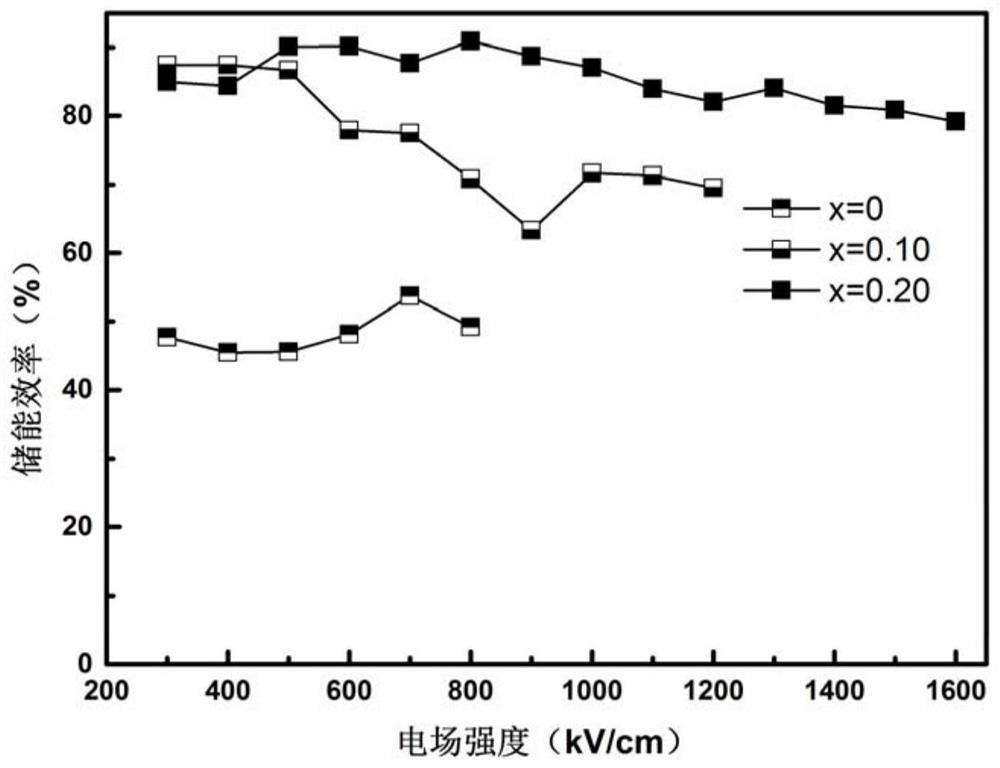

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com