Purging and purifying system inside hydrogen generator

A purification system and generator technology, applied in cells, electrolysis processes, electrolysis components, etc., can solve the problems of complex process pipelines of hydrogen production devices, inability to realize automatic control, and inability to turn on hydrogen production, and reduce production investment. cost, the effect of automation control, simplified process and operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

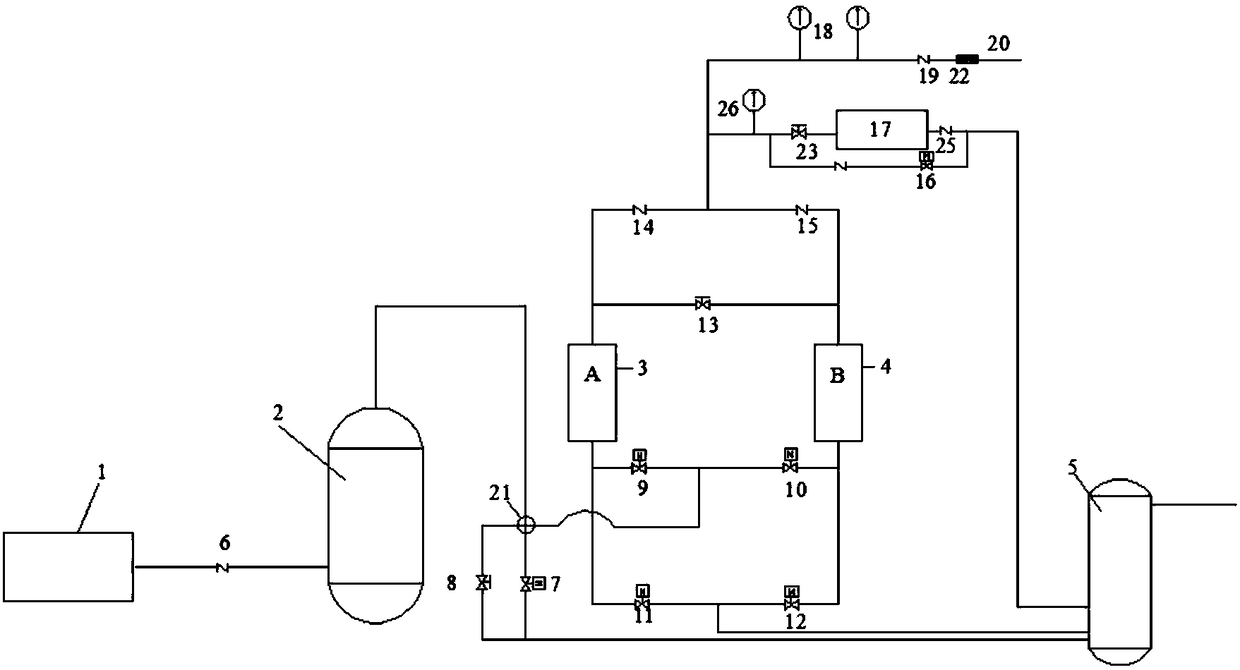

[0030] A purging and purification system inside a hydrogen generator, comprising a hydrogen generator 1, a gas-water separator 2, a liquid seal 5 and a hydrogen purifier connected through pipelines, the hydrogen generator 1 is connected to the Gas-water separator 2 is connected, and described hydrogen purifier comprises purifier A cylinder 3 and purifier B cylinder 4, and the bottom of purifier A cylinder 3 is provided with solenoid valve 2 9, and the bottom of purifier B cylinder 4 is provided with solenoid valve Three 10, solenoid valve two 9 and solenoid valve three 10 are connected in series to form circuit one, and the lower part of purifier A cylinder 3 and purifier B cylinder 4 is also provided with circuit two in parallel with circuit one, and solenoid valve four 11 and Solenoid valve five 12.

[0031] The upper part of the purifier A cylinder 3 and the purifier B cylinder 4 is connected through a pipeline and is provided with a pressure regulating valve 6 13, the puri...

Embodiment 2

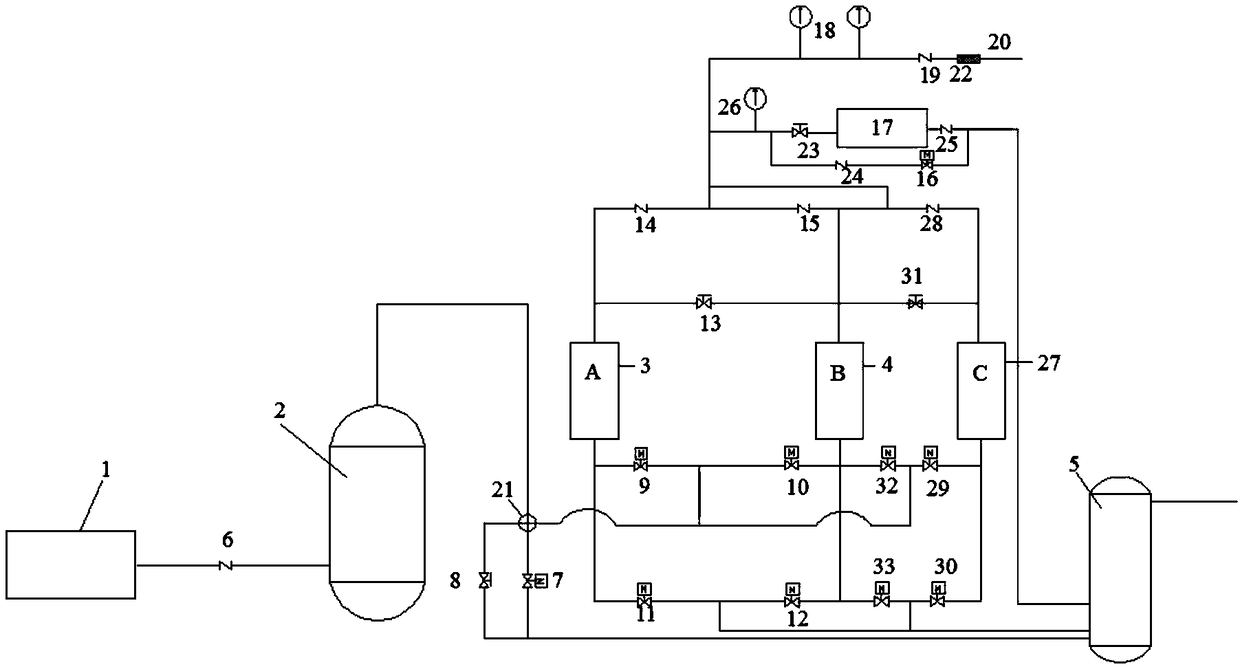

[0042] A purging and purification system inside a hydrogen generator, comprising a hydrogen generator 1, a gas-water separator 2, a liquid seal 5 and a hydrogen purifier connected through pipelines, the hydrogen generator 1 is connected to the The gas-water separator 2 is connected, and the hydrogen purifier includes a purifier A cylinder 3, a purifier B cylinder 4, and a purifier C cylinder 27. The lower part of each purifier cylinder is provided with a circuit 1 through the pipeline. On the circuit 1, a solenoid valve 2 9 and a solenoid valve 3 10 are arranged between the purifier A cylinder 3 and the purifier B cylinder 4. On the circuit 1, the purifier B cylinder 4 Electromagnetic valve seventeen 32 and electromagnetic valve fourteen 29 are also arranged between the remaining purifier C cylinders 27. The lower part of purifier A cylinder 3, purifier B cylinder 4, purifier C cylinder 27 is also provided with circuit 2 in parallel with circuit 1, and circuit 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com