A method for synergistic production of hydrogen by photocatalytic treatment of wastewater

A technology for treating wastewater and photocatalysis, applied in chemical instruments and methods, light water/sewage treatment, hydrogen production, etc., to achieve the effects of easy recycling, improved photocatalytic efficiency, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

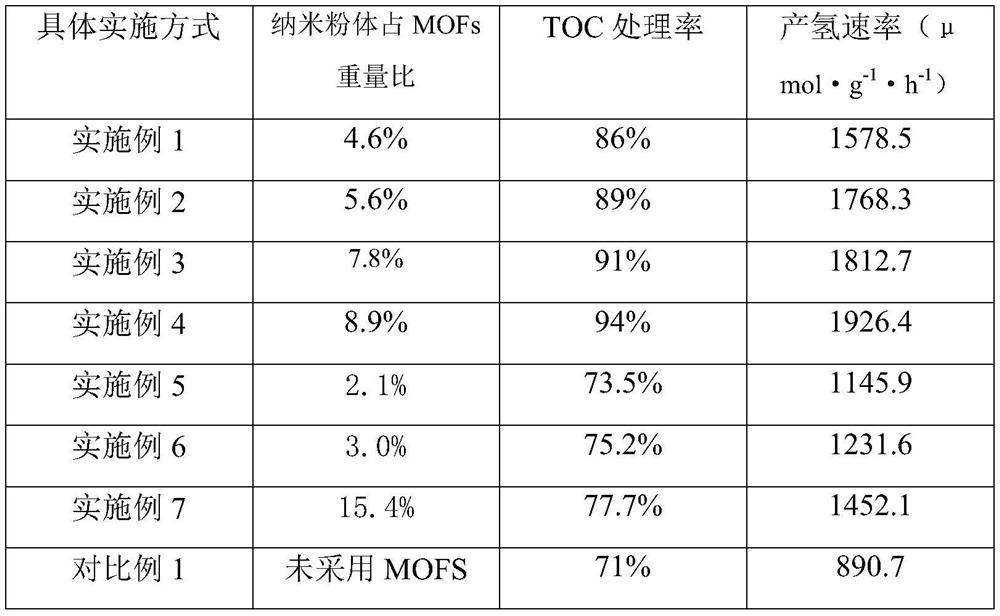

Examples

Embodiment 1

[0023] 1) Add 4 grams of bismuth salt to 1 ml of concentrated nitric acid, add deionized water after preliminary stirring, and after stirring evenly, add dropwise to the ammonium chloride solution with a concentration of 2 mol%, and stir while adding , to form a uniform suspension, adjust the pH of the solution to be neutral with 25% sodium hydroxide, then put it into a stainless steel autoclave, and react at a temperature of 200 ° C for 10 minutes. After the reaction, the precipitated product is washed with deionized water After washing and drying at a temperature of 100°C, the BiOCl nanopowder is obtained;

[0024] 2) Disperse the BiOCl nano-powder prepared in step 1) in deionized water to make a dispersion liquid, and immerse MIL-101 into the BiOCl nano-powder dispersion liquid according to the weight ratio of 4.6% loading, keep 7 hours, then take out the MIL-101 loaded with BiOCl nanopowder, and dry it at a temperature of 100°C to obtain a BiOCl / MIL-101 composite material;...

Embodiment 2

[0027] 1) Add 4.5 grams of bismuth salt to 1 ml of concentrated nitric acid, add deionized water after preliminary stirring, and after stirring evenly, add dropwise to 2 mol% ammonium chloride solution, stirring while adding , form a uniform suspension, adjust the pH of the solution to be neutral with 25% sodium hydroxide, then put it into a stainless steel autoclave, and react for 8.5 minutes at a temperature of 220 ° C. After the reaction, the precipitated product is washed with deionized water After washing and drying at a temperature of 100°C, the BiOCl nanopowder is obtained;

[0028] 2) Disperse the BiOCl nano-powder prepared in step 1) in deionized water to make a dispersion liquid, and immerse MIL-100 into the BiOCl nano-powder dispersion liquid according to the weight ratio of 5.6% loading, keep 8 hours, then take out the MIL-100 loaded with BiOCl nanopowder, and dry it at a temperature of 100°C to obtain a BiOCl / MIL-100 composite material;

[0029] 3) Put the prepar...

Embodiment 3

[0031] 1) Add 5.5 grams of bismuth salt to 1.5 milliliters of concentrated nitric acid, add deionized water after preliminary stirring, and after stirring evenly, add dropwise to the ammonium chloride solution with a concentration of 3 mol%, and stir while adding , to form a uniform suspension, adjust the pH of the solution to be neutral with 33% sodium hydroxide, then put it into a stainless steel autoclave, and react at a temperature of 250°C for 13 minutes. After the reaction, the precipitated product is washed with deionized water After washing and drying at a temperature of 110°C, the BiOCl nanopowder is obtained;

[0032] 2) Disperse the BiOCl nano-powder prepared in step 1) in deionized water to make a dispersion liquid, and immerse MIL-53 into the BiOCl nano-powder dispersion liquid according to the weight ratio of 7.8% loading, keep 9 hours, then take out the MIL-53 loaded with BiOCl nanopowder, and dry it at a temperature of 110°C to obtain a BiOCl / MIL-53 composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com