A salt-made porous magnesium-nickel hydrolysis hydrogen production alloy and its preparation method

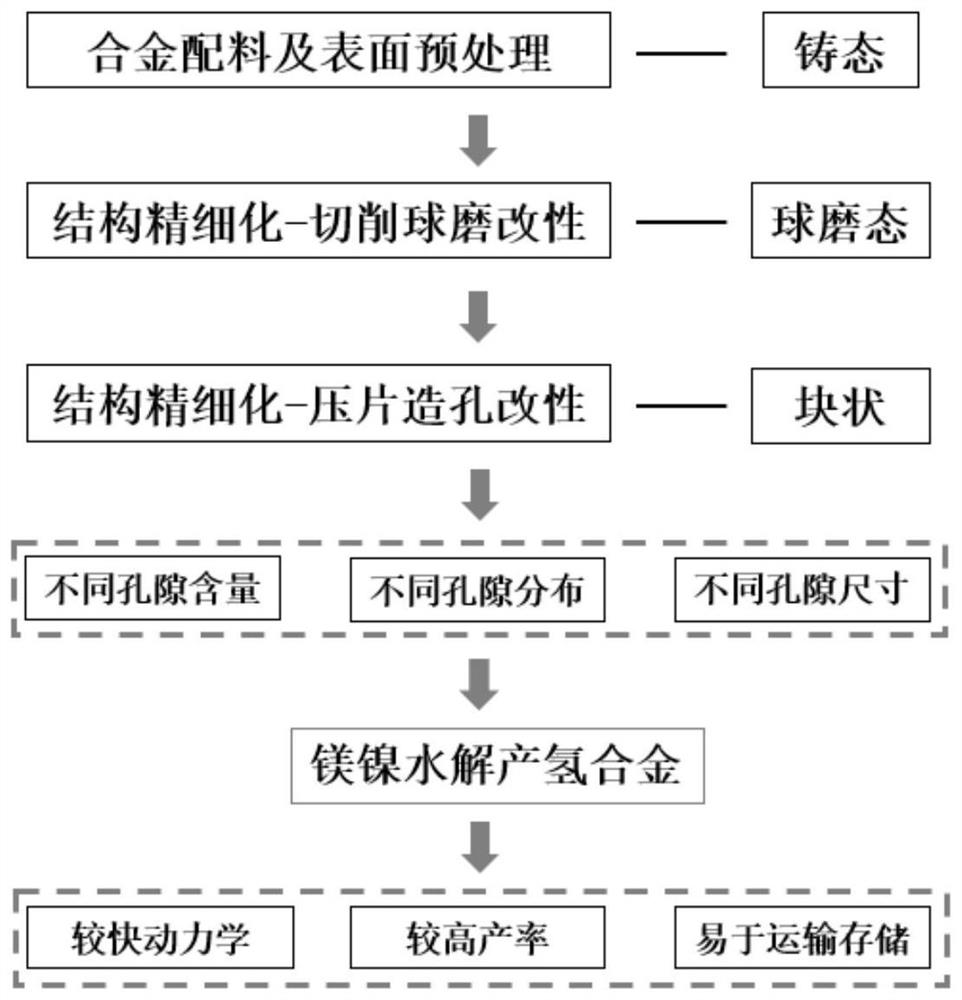

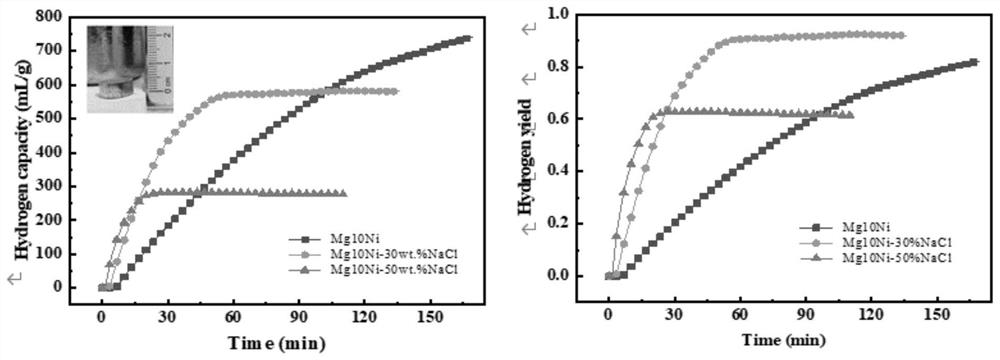

A technology of hydrogen production by hydrolysis and porous magnesium, applied in the production of hydrogen, etc., can solve the problems of harsh pore-forming conditions, complex process flow, high energy consumption, etc., to improve the yield of hydrogen production by hydrolysis, increase the dissolution temperature, and promote mass transfer The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The salt-made porous magnesium-nickel hydrolysis hydrogen production alloy of the present invention is composed of Mg-10wt.% Ni magnesium-rich alloy and salt as a pore-forming agent, wherein the pore-forming salt accounts for 0-50wt.%, and the rest is Mg-10wt.%. Ni alloy.

[0036] Step 1, alloy batching and surface pretreatment: select metal magnesium blocks with a purity of ≥99.8% and a 30% magnesium-nickel master alloy, with a magnesium content of 90wt.% and a nickel content of 10wt.%. Considering burning loss, magnesium Add 2wt.% burning loss; carry out surface pretreatment on the obtained Mg-Ni alloy, the pretreatment method includes but not limited to degreasing, grinding, polishing, etc., to obtain a magnesium alloy with metallic luster and no oxide layer on the surface.

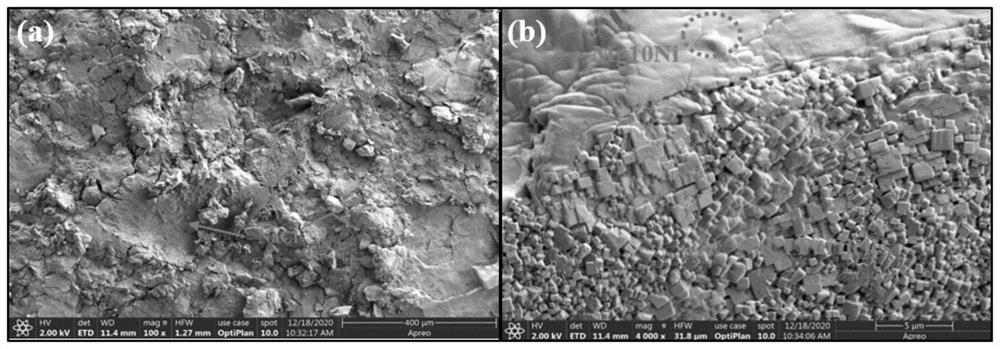

[0037]Step 2, alloy cutting and ball milling modification: cutting the magnesium alloy obtained in step 1 to preliminarily obtain a small-sized magnesium alloy block. Use a high-speed vibrating...

Embodiment 2

[0040] The salt-made porous magnesium-nickel hydrolysis hydrogen production alloy of the present invention is composed of Mg-10wt.% Ni magnesium-rich alloy and salt as a pore-forming agent, wherein the pore-forming salt accounts for 0-50wt.%, and the rest is Mg-10wt.%. Ni alloy.

[0041] Step 1, alloy batching and surface pretreatment: select metal magnesium blocks with a purity of ≥99.8% and a 30% magnesium-nickel master alloy, with a magnesium content of 90wt.% and a nickel content of 10wt.%. Considering the burning loss, magnesium Adding 2wt.% burning loss; performing surface pretreatment on the obtained Mg-Ni alloy, the pretreatment methods include but not limited to degreasing, grinding, polishing, etc., to obtain a magnesium alloy with metallic luster and no oxide layer on the surface.

[0042] Step 2, alloy cutting and ball milling modification: cutting the magnesium alloy obtained in step 1 to preliminarily obtain a small-sized magnesium alloy block. Use a high-speed ...

Embodiment 3

[0045] The salt-made porous magnesium-nickel hydrolysis hydrogen production alloy of the present invention is composed of Mg-10wt.% Ni magnesium-rich alloy and salt as a pore-forming agent, wherein the pore-forming salt accounts for 0-50wt.%, and the rest is Mg-10wt.%. Ni alloy.

[0046] Step 1, alloy batching and surface pretreatment: select metal magnesium blocks with a purity of ≥99.8% and a 30% magnesium-nickel master alloy, with a magnesium content of 90wt.% and a nickel content of 10wt.%. Considering the burning loss, magnesium Adding 2wt.% burning loss; performing surface pretreatment on the obtained Mg-Ni alloy, the pretreatment methods include but not limited to degreasing, grinding, polishing, etc., to obtain a magnesium alloy with metallic luster and no oxide layer on the surface.

[0047] Step 2, alloy cutting and ball milling modification: cutting the magnesium alloy obtained in step 1 to preliminarily obtain a small-sized magnesium alloy block. Use a high-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com