Method for preparing hydrogen from iron scraps and waste sulfuric acid by anaerobic corrosion reaction

A technology of anaerobic corrosion and waste sulfuric acid, which is applied in the production of hydrogen, can solve social and environmental hazards and other problems, and achieve the effects of large hydrogen production, low energy consumption, good economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

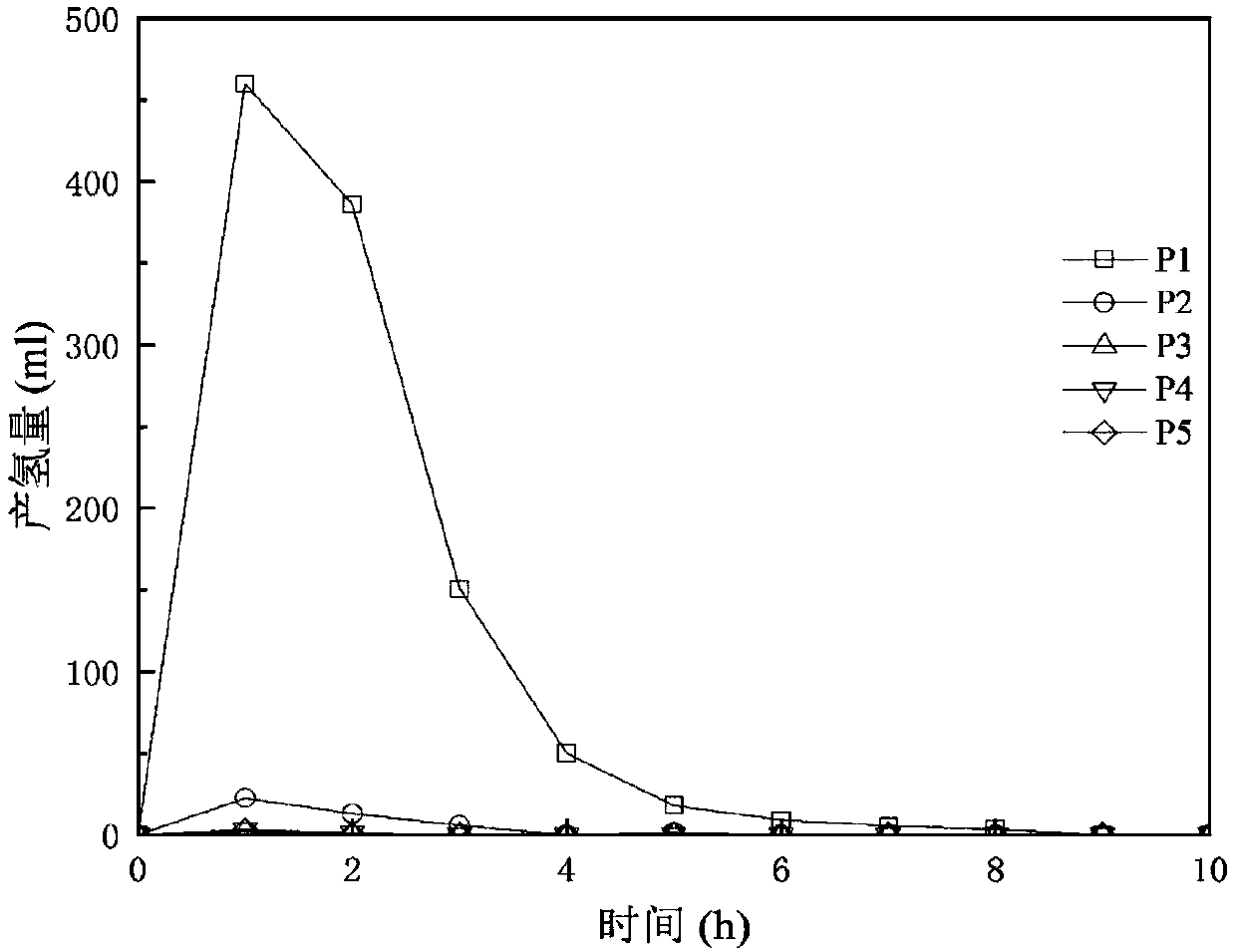

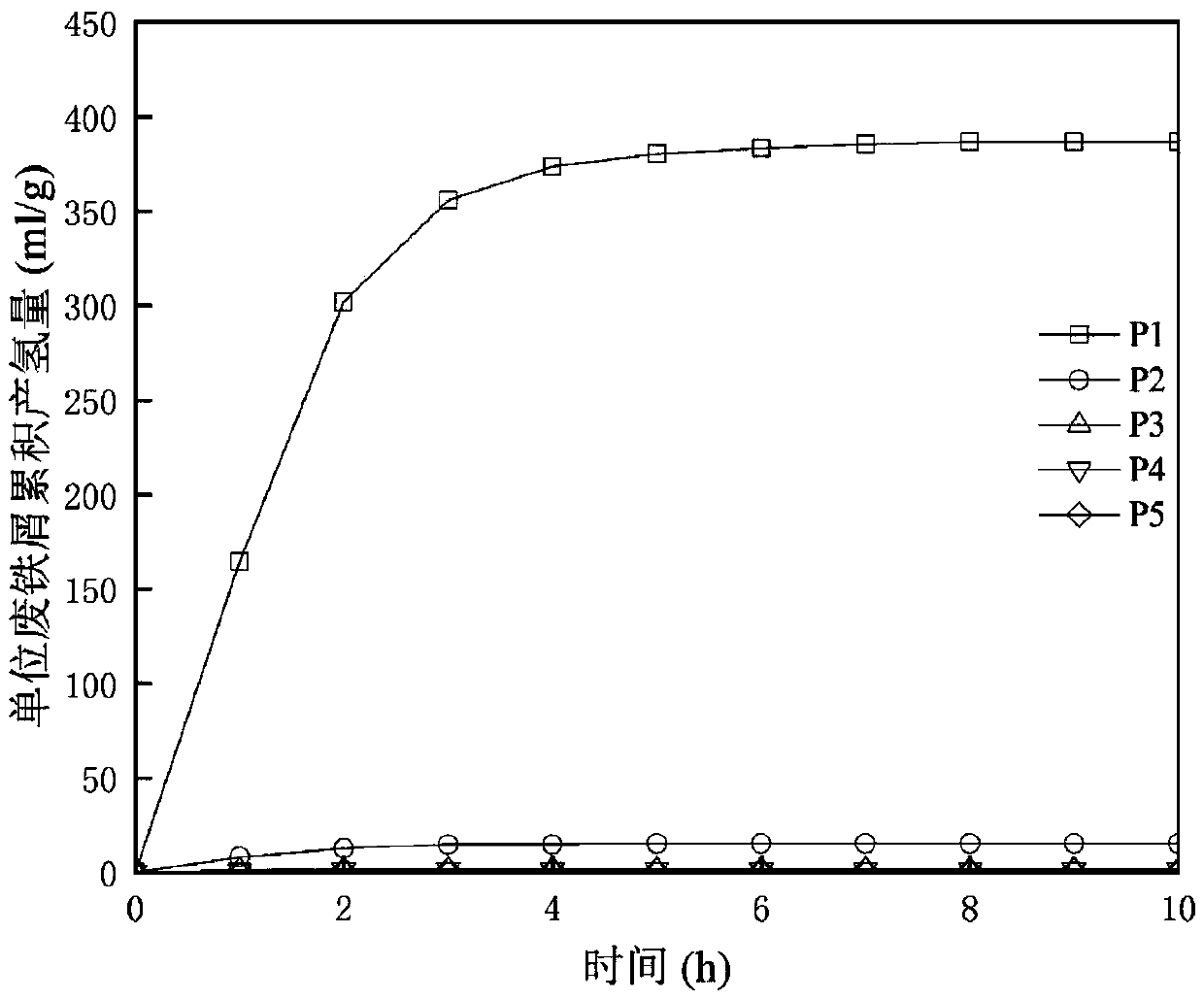

Embodiment 1

[0029] Prepare a spent sulfuric acid solution with a pH of 0 at room temperature, fill 250ml into a 300ml serum bottle, and fill with N 2 5 minutes to ensure the anaerobic environment in the bottle, then add 2.8g of scrap iron chips with a particle size of 2mm, seal it with a rubber stopper, and let it stand at room temperature. The hydrogen production was recorded every hour by the drainage gas collection method, and the hydrogen content was determined by gas chromatography.

Embodiment 2

[0031] Prepare waste sulfuric acid solution with a pH of 2 at room temperature, fill 250ml into a 300ml serum bottle, fill with N 2 5 minutes to ensure the anaerobic environment in the bottle, then add 2.8g of scrap iron chips with a particle size of 2mm, seal it with a rubber stopper, and let it stand at room temperature. The hydrogen production was recorded every hour by the drainage gas collection method, and the hydrogen content was determined by gas chromatography.

Embodiment 3

[0033] Prepare waste sulfuric acid solution with a pH of 4 at room temperature, fill 250ml into a 300ml serum bottle, fill with N 2 5 minutes to ensure the anaerobic environment in the bottle, then add 2.8g of scrap iron chips with a particle size of 2mm, seal it with a rubber stopper, and let it stand at room temperature. The hydrogen production was recorded every hour by the drainage gas collection method, and the hydrogen content was determined by gas chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com