Stirring drill pipe internally provided with core tube

A technology for stirring drill pipes and core pipes, which is applied in the direction of drill pipes, drill pipes, casings, etc., and can solve problems such as poor sealing performance, complicated drill pipe structure and installation, and oil pipe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

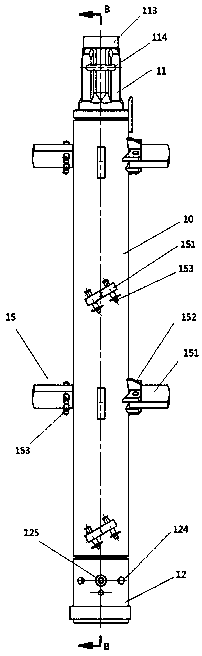

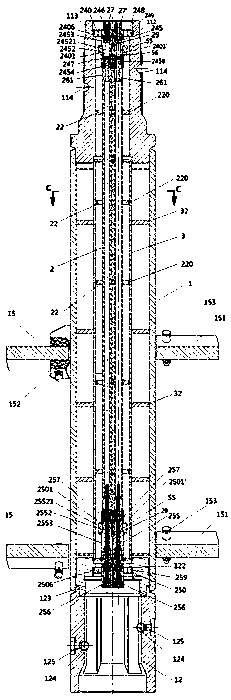

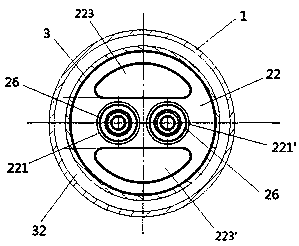

[0050] The agitating drill pipe with a built-in core pipe of the present invention will be further described below in conjunction with the accompanying drawings.

[0051] A stirring drill pipe with a built-in core tube, comprising: a male joint body 11 with a through hole, a female joint socket 12, a hollow drill pipe 1 with multiple sets of stirring wings 15, and a built-in oil pipe assembly 2 arranged in the hollow drill pipe And have the grouting pipe 3 of support 32, upper end retaining ring 248, upper end sealing ring 249, lower end retaining ring 258 and lower end sealing ring 259, wherein:

[0052] The male joint body 11 includes a first stepped step 112 located in the through hole on its upper end surface, a male joint journal 113 located on its upper outer wall, and a first transverse semicircular groove 114 located on the outer wall of its middle; the female joint socket 12 includes a The second stepped step 122, the third stepped step 123, the second transverse semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com