Double-feedback fan blade hub axial extension device and double-feedback fan thereof

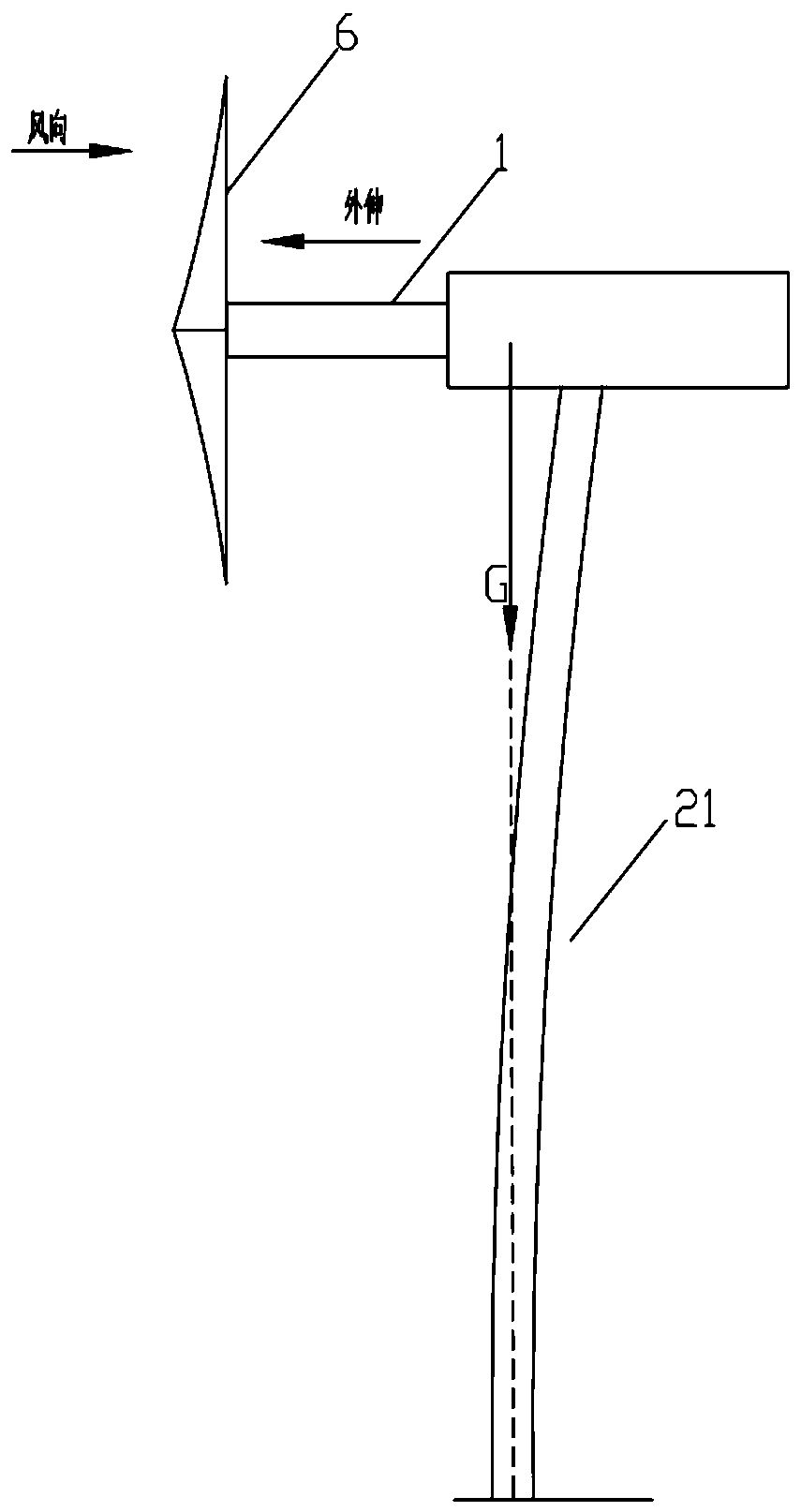

A doubly-fed wind turbine, axial telescopic technology, applied to wind turbines in the same direction as the wind, the configuration of installing/supporting wind turbines, wind turbines, etc., can solve the collapse of the tower 21, accelerated failure of other components of the supporting connection structure, Destruction of bending moment and other problems, to improve the operation safety and service life, to avoid the effect of tower collapse accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

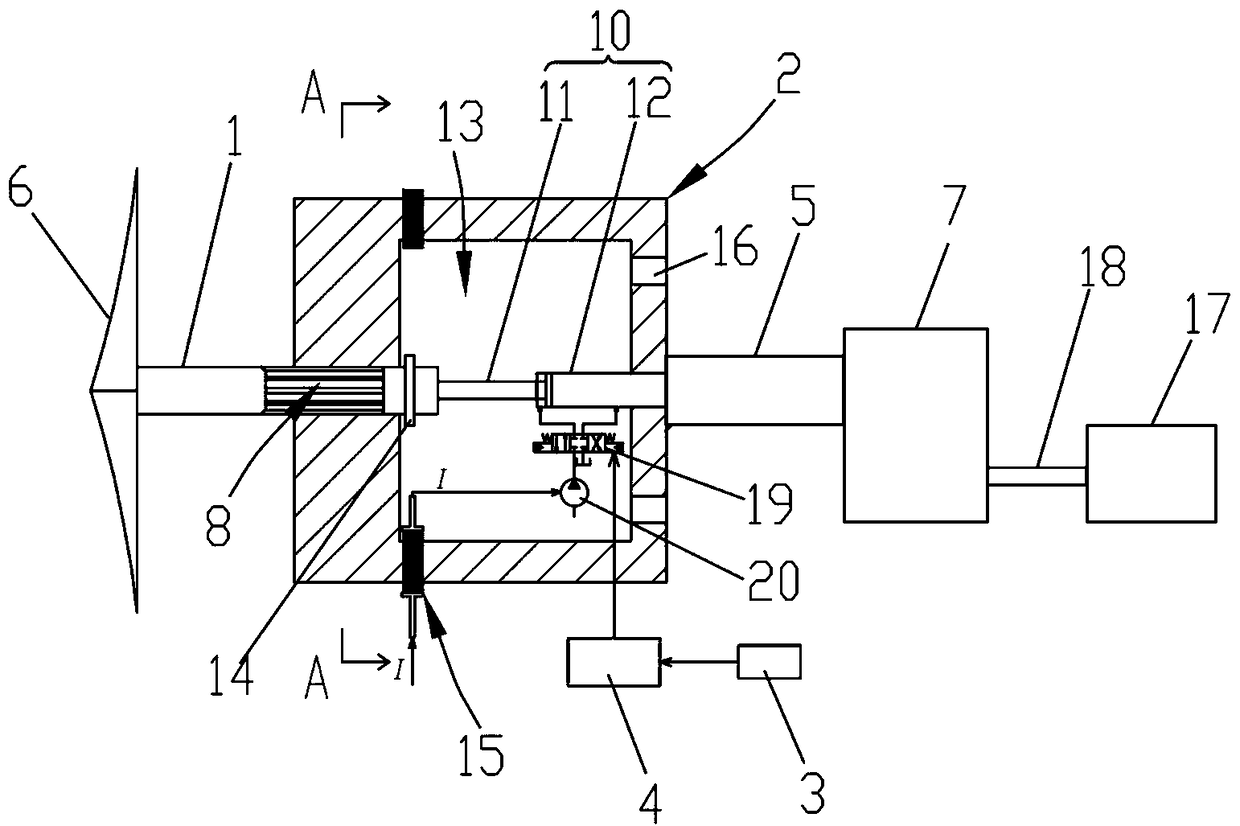

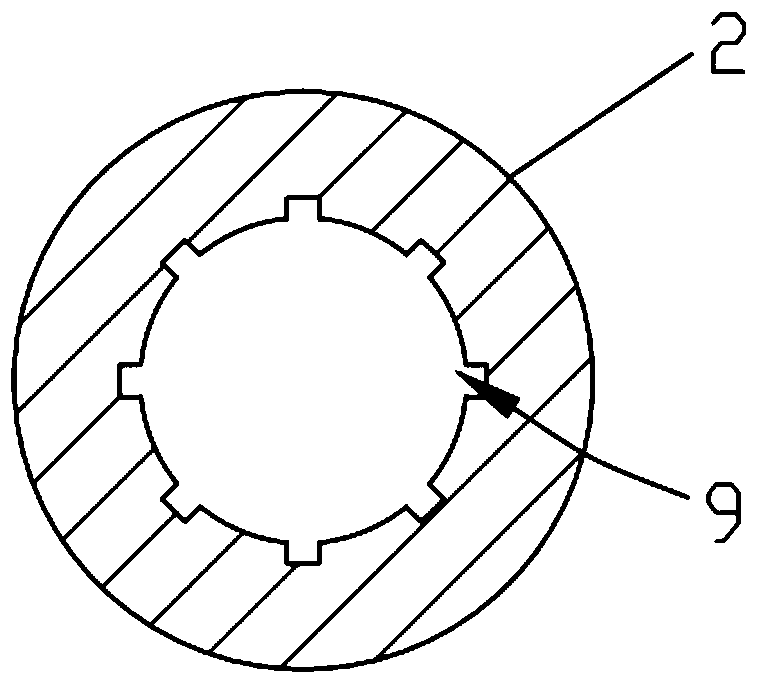

[0026] Such as Figure 1-Figure 3 As shown, the present invention first discloses a double-fed fan blade hub axial expansion device, including a hub shaft 1, a telescopic mechanism, a shaft sleeve 2, a wind speed sensor 3, a controller 4, and an output shaft 5. The telescopic mechanism can be Pneumatic drive, hydraulic drive, rack and pinion, ball screw or similar mechanism that can complete the telescopic function. In this embodiment, the telescopic mechanism is a hydraulic cylinder 10, the piston rod 11 of the hydraulic cylinder 10 is connected to the hub shaft 1, and the hydraulic cylinder The cylinder 12 of 10 is connected with one end of the output shaft 5, that is, when the piston rod 11 rotates, it will not rotate with the cylinder 12. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com