Automated Valve Mechanism for Dewatering Integrated Equipment

A technology for washing water and equipment, applied in the field of automatic valve mechanism, can solve the problems of inability to control and close in time, affecting the working environment, heavy and laborious rotation, etc., and achieves the effect of low production cost, convenient and fast operation, and avoidance of opening and closing work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

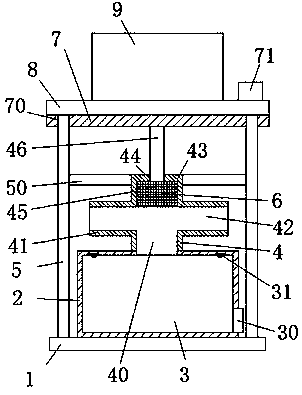

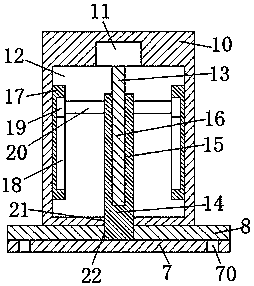

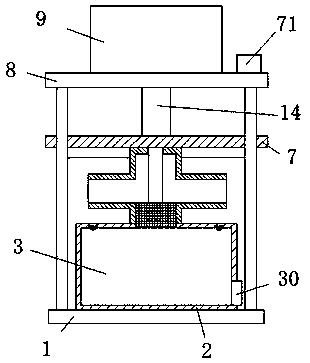

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as Figure 1-Figure 3 As shown, an automatic valve mechanism for an integrated water-washing device of the present invention includes a fixed base 1 and an equipment water tank main body 2 fixedly installed on the fixed base 1, and the fixed base 1 is placed on the The left and right ends of the main body of the equipment water tank 2 are symmetrically provided with polished rods 5 extending upward. The top of the polished rod 5 is fixedly provided with a top support 8, and the middle of the top surface of the top support 8 is fixedly provided with a valve driving body 9. The equipment water tank A water inlet pipe 4 is installed on the top of the main body 2, and a water delivery pipe 41 extending left and right is installed on the top of the water inlet pipe 40. A valve cover 43 is installed on the top of the water delivery pipe 41, and a water delivery hole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com