Vapor chamber cooling device with heat conduction pipe

A technology of a heat sink and a temperature equalizing plate, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of short service life, poor temperature uniformity, and high manufacturing cost, and achieve long service life and good temperature uniformity. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

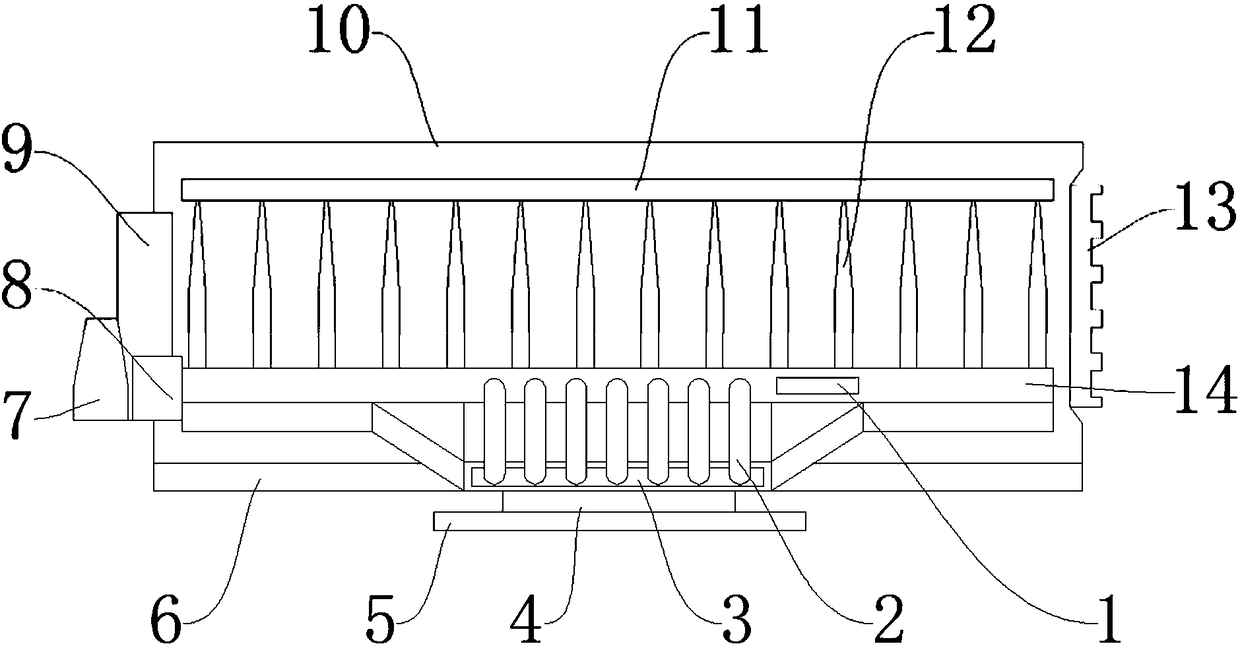

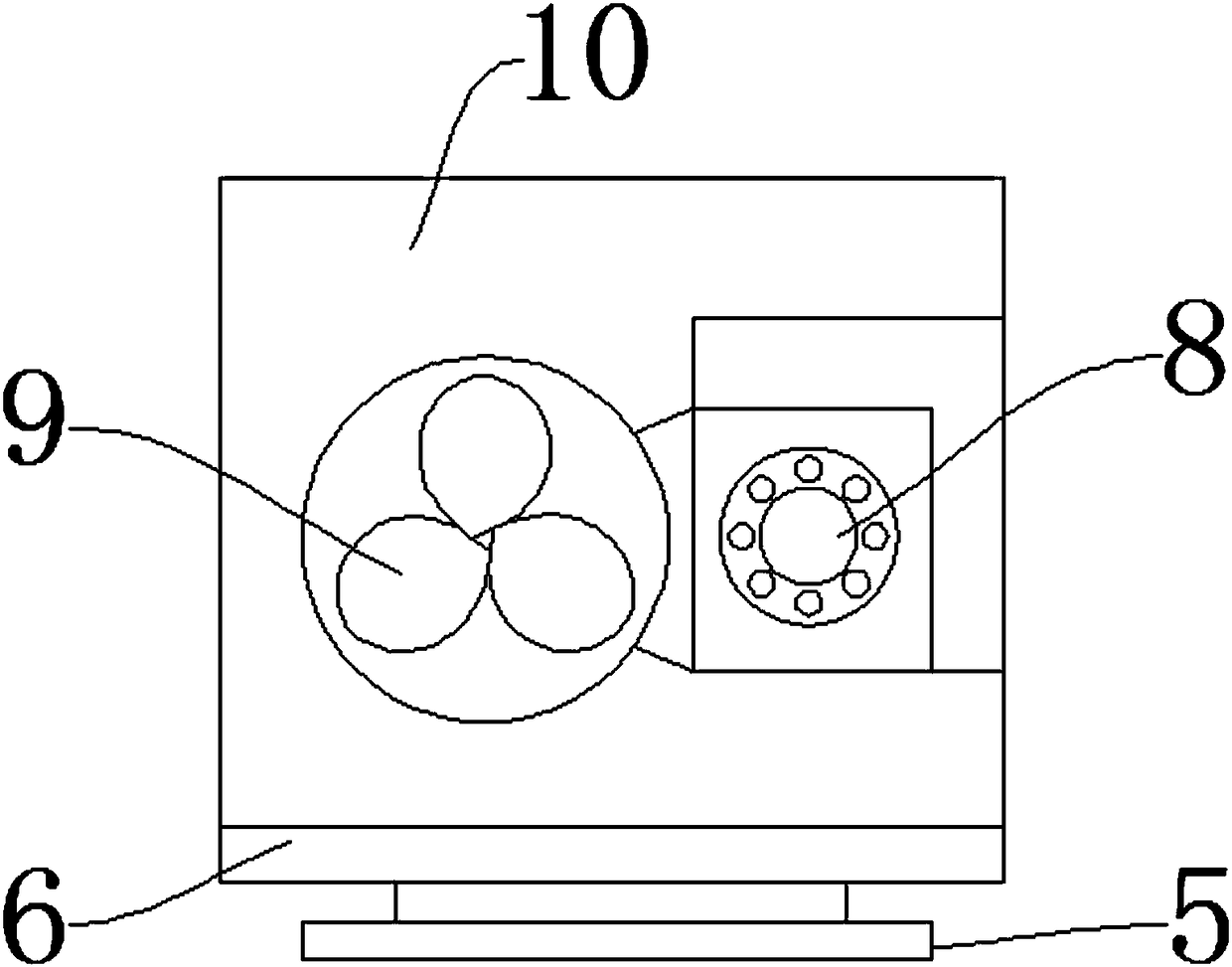

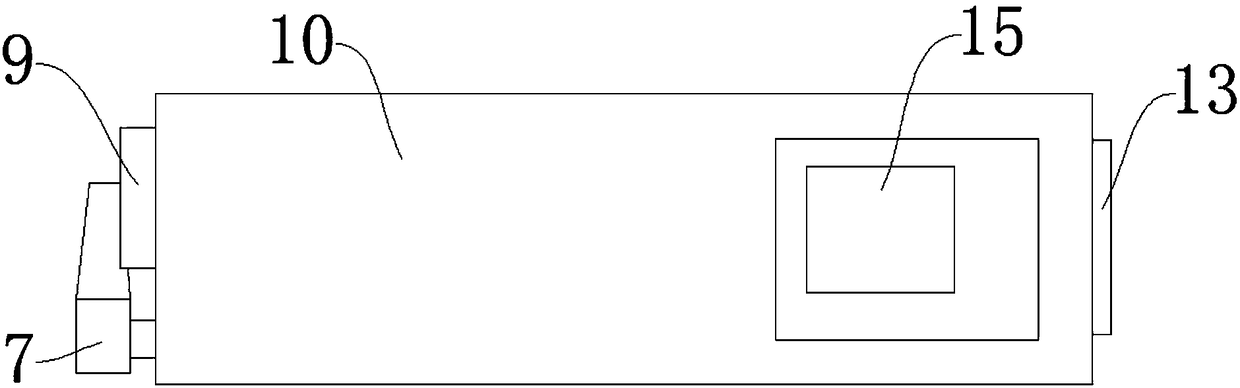

[0020] Such as Figure 1-Figure 3 As shown, a vapor chamber cooling device with a heat pipe includes a temperature sensor 1, a capillary core module 3, heat dissipation fins 12, a vapor chamber 14, and a controller 15, and a heating element 4 is arranged under the capillary core module 3 , the capillary core module 3 is used to increase the contact area with the heating element 4 to increase the heat dissipation speed, the heating element 4 is used to install the capillary core module 3, a support platform 5 is installed under the heating element 4, and the support platform 5 is used to support the heat dissipation element, A heat pipe 2 is arranged above the capillary core module 3, and the heat pipe 2 is used to conduct heat to a vapor chamber 14. The side away from the temperature sensor 1 is provided with a motor 8, the motor 8 is used to drive the fan 9 to rotate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com