Super compression treatment system of nuclear power stations

A processing system and compression processing technology, which is applied in nuclear engineering, radioactive purification, etc., can solve the problems of waste gas and waste leakage, achieve the effects of reducing occupied space, preventing the leakage and diffusion of radioactive substances, and reducing the risk of radiation exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

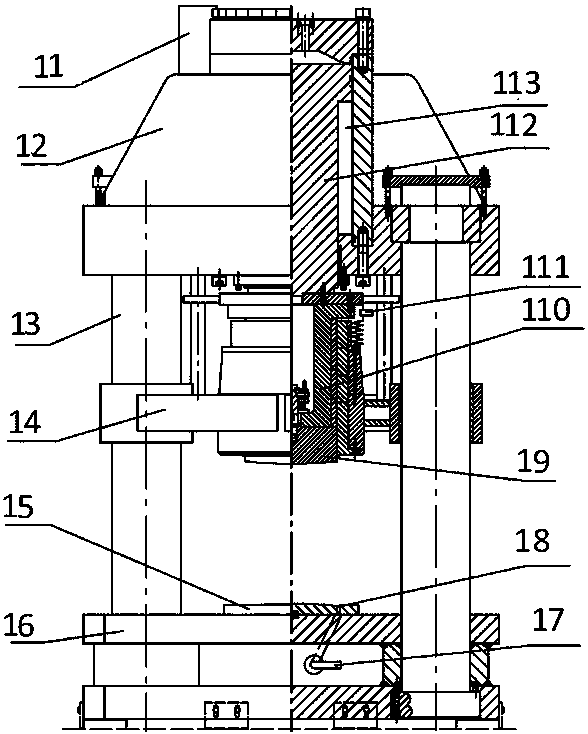

[0027] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

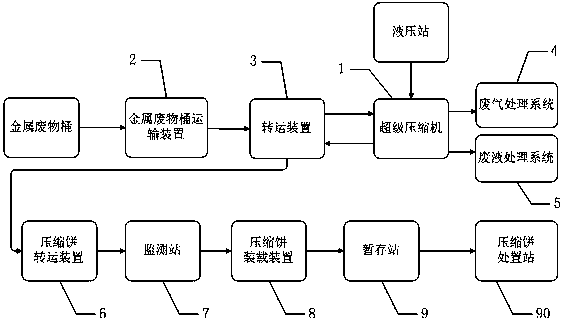

[0028] Embodiments of the present invention provide a nuclear power plant super-compression treatment system, which can use super-compression treatment technology to process scrapped metal waste barrels, such as figure 1 As shown in the system work flow chart, the nuclear power plant metal waste barrel processing system may include:

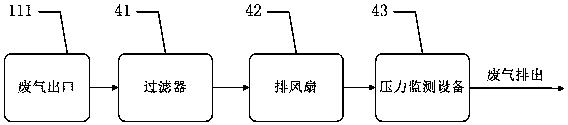

[0029] The metal waste barrels that need to be scrapped are transferred to the transfer device 3 through the metal waste barrel transport device 2; then transferred to the super compressor 1 in the hydraulic station through the transfer device 3; the metal waste barrels are squeezed into metal waste barrels through the super compressor 1 The compressed cake is then transferred to the compressed cake transfer device 6 through the transfer device 3; the super compressor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com