Safe cable

A technology of safe cables and wires, which is applied in the field of transmission, can solve the problems of cables being separated, different, hanging on the ceiling, and some are placed on the floor surface and inside the wall, etc., to improve safety, enhance firmness, The effect of protecting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

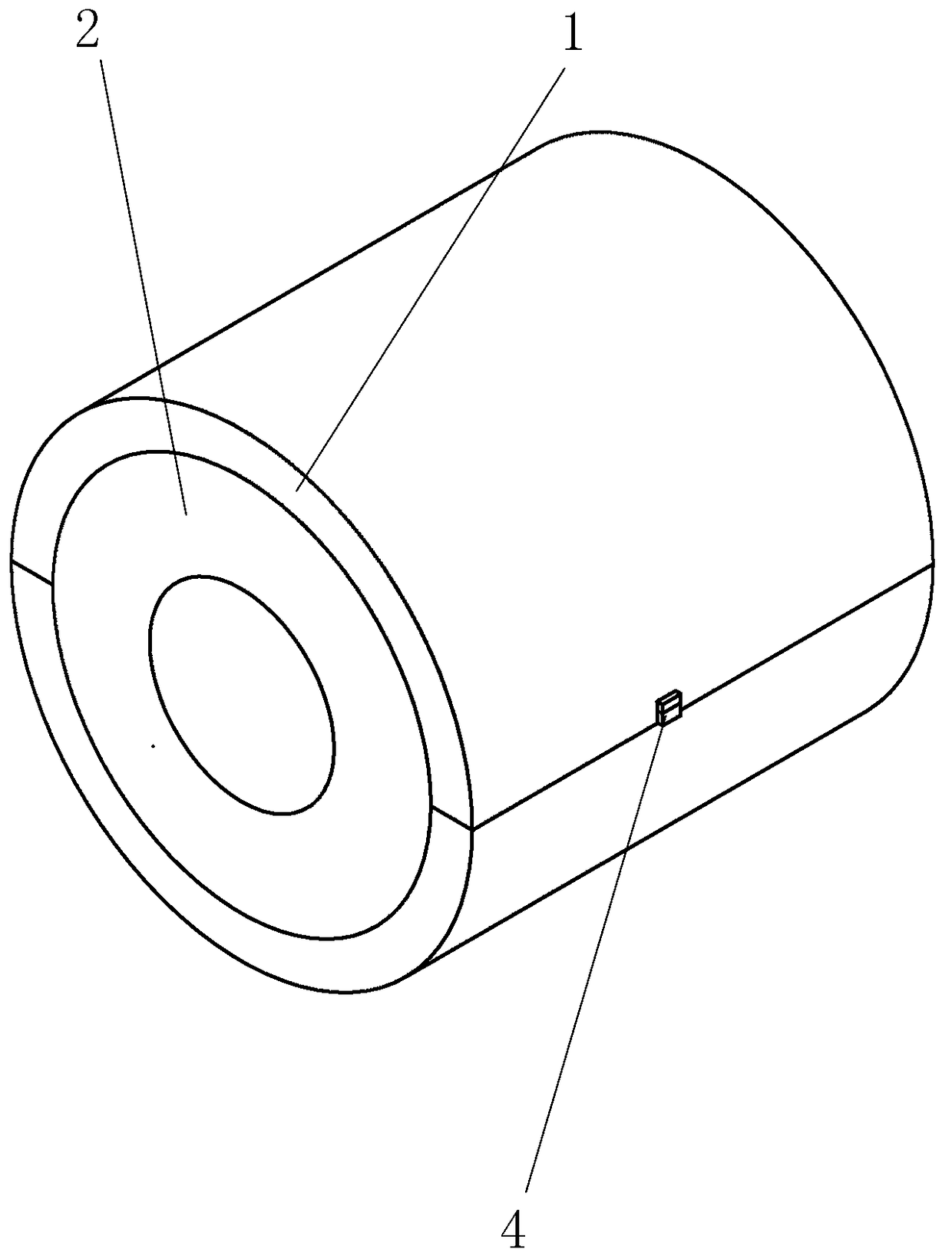

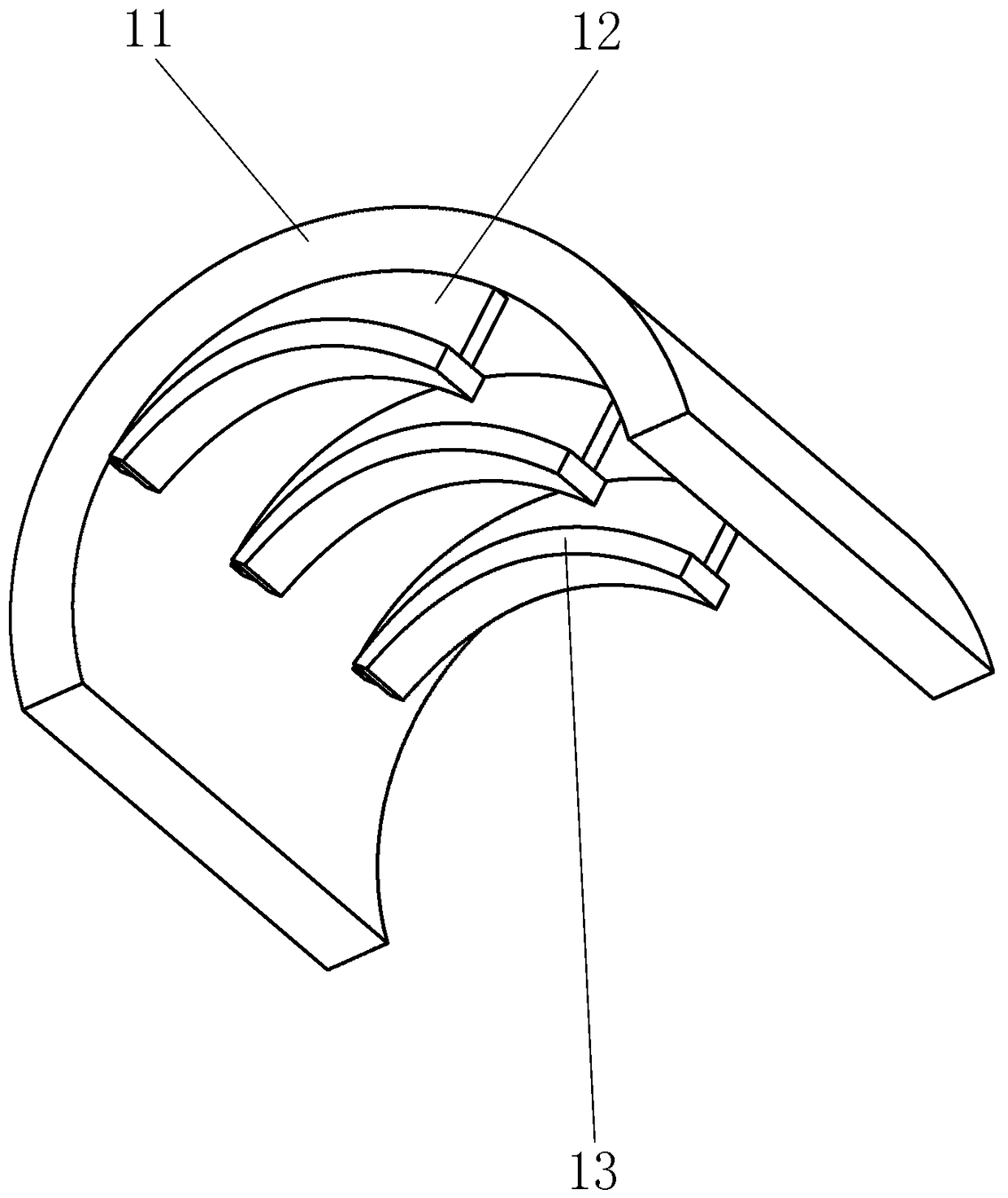

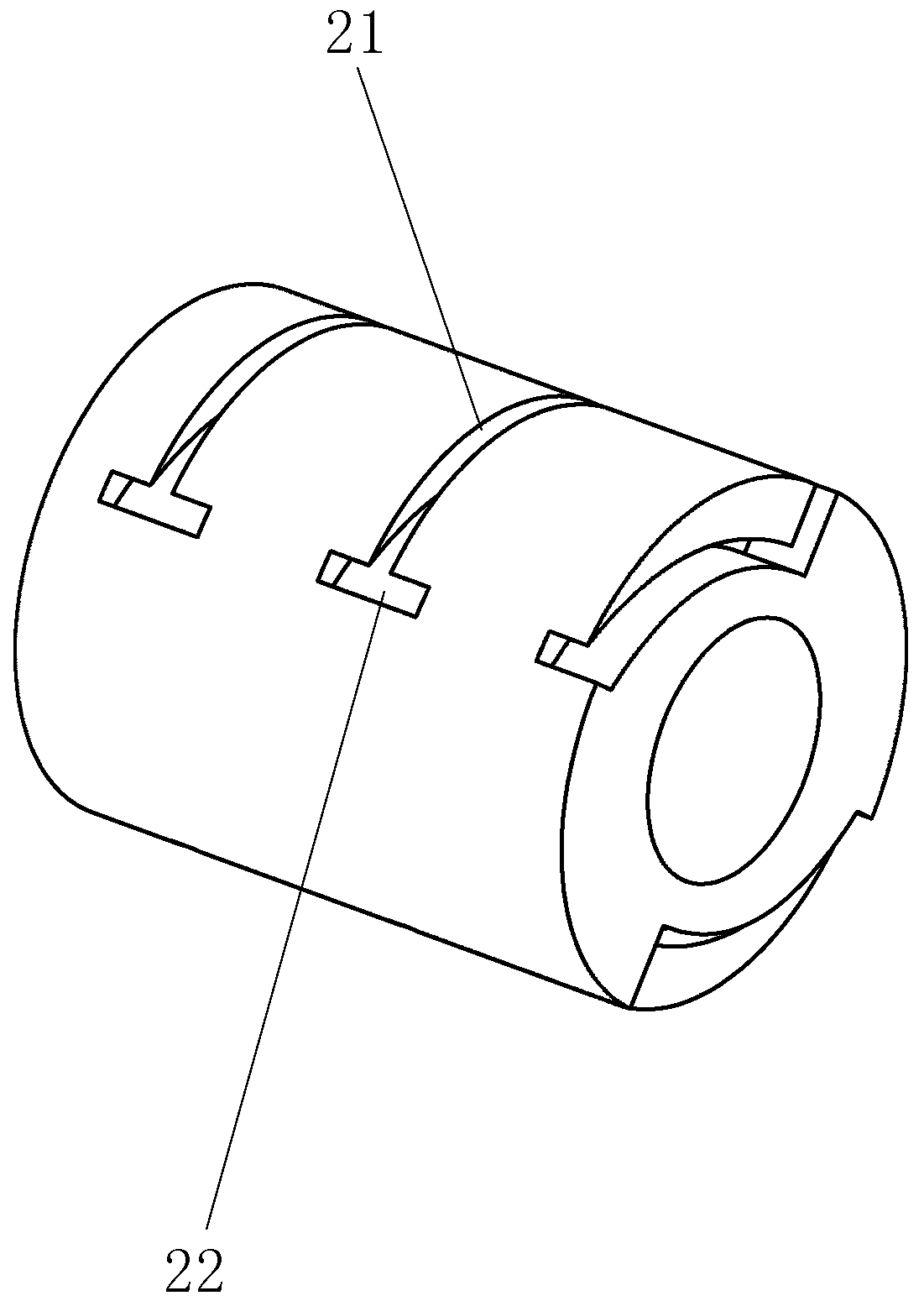

[0027] Example 1, such as figure 1 Shown is a schematic cross-sectional view of the overall structure of the cable, a safety cable, including wires and anti-expansion shells, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the anti-expansion shell includes a slow-change layer 1 and an inner layer 2. The inner layer 2 is a circular straight bar. There is a filling cavity on the inner layer 2. The filling cavity includes a communicating cavity 21 and a gradually deepening cavity 22. The communication cavity 21 is a concave groove whose depth gradually increases along the circumferential wall surface of the inner layer 2, and the gradually deepening cavity 22 is a rectangular groove extending in reverse from the end side of the vertical communication cavity 21, and is filled into the inner layer of the cavity. 2 are arranged at intervals in the axial direction, and the slow-change layer 1 includes an outer arc surface 11 for fitting the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com