An equipment station with fire extinguishing function

A technology of equipment stations and functions, applied in the direction of fire rescue, etc., can solve problems such as property safety impacts, and achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

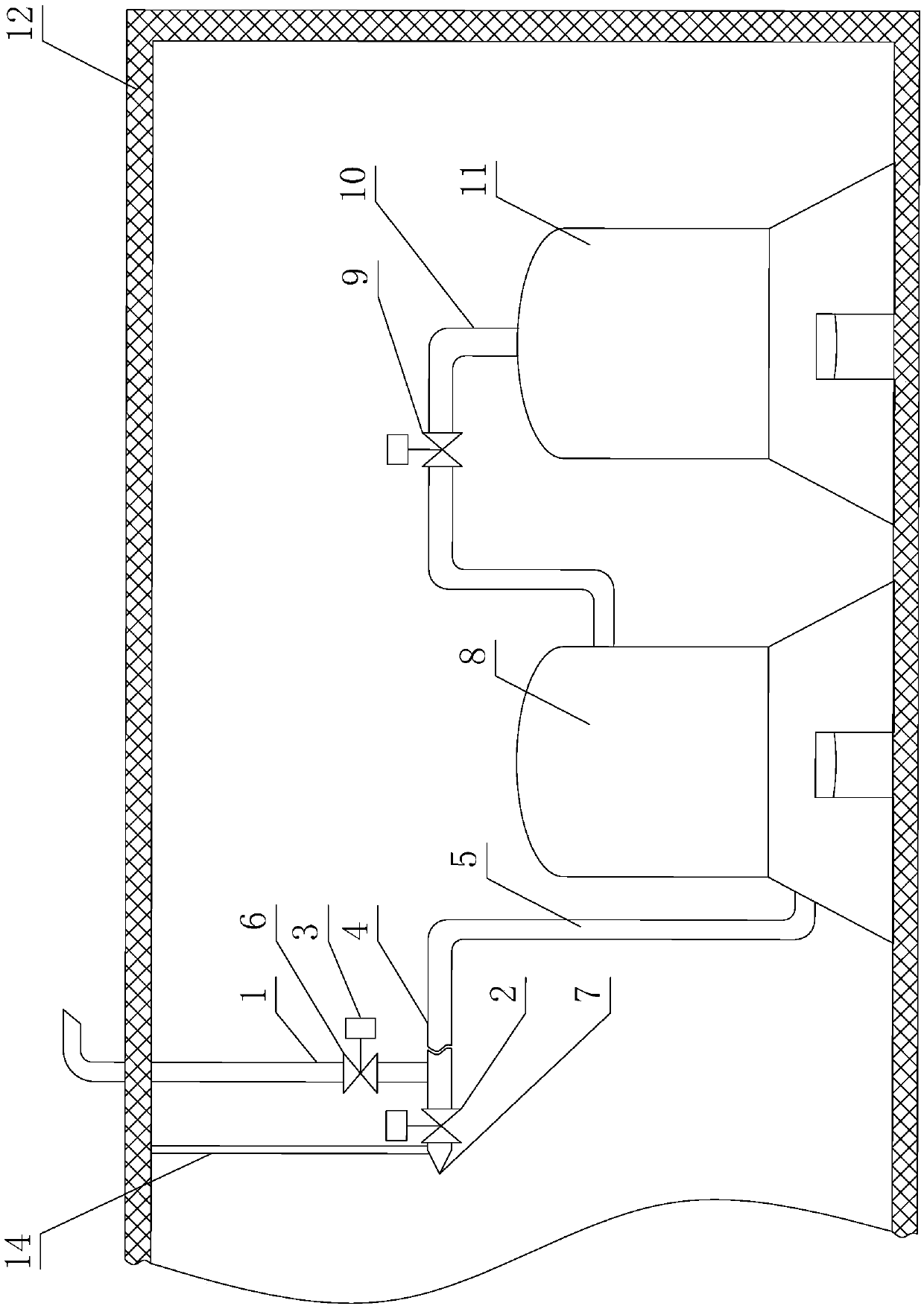

[0039] Such as Figure 1 to Figure 3 As shown, an equipment station with a fire extinguishing function includes a factory building 12 and a dry powder output system installed in the factory building 12. It is characterized in that the dry powder output system includes an air source device 11, a dry powder container 8, an air source pipe 10 and output pipe 5;

[0040] The air source pipe 10 is used as a communication pipe between the air source device 11 and the dry powder container 8, and the first shut-off valve 9 is connected in series on the air source pipe 10;

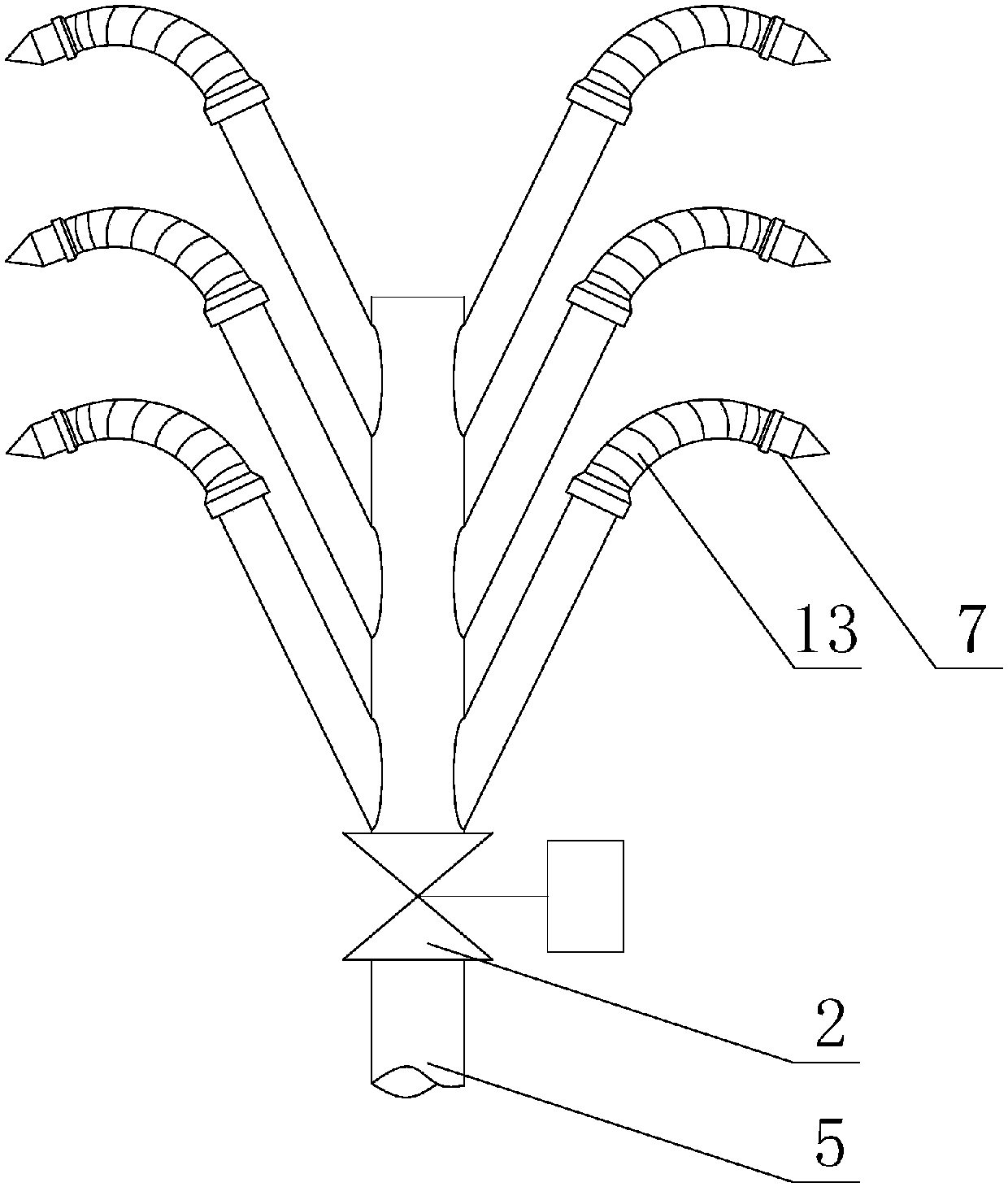

[0041] One end of the outlet pipe 5 is connected to the dry powder container 8, and the other end of the outlet pipe 5 is provided with a nozzle 7;

[0042] It also includes a third cut-off valve 2 connected in series on the output pipe 5;

[0043] Both the first cut-off valve 9 and the third cut-off valve 2 are connected with a drive mechanism 3 for driving each to change the on-off state, and the drive mechanis...

Embodiment 2

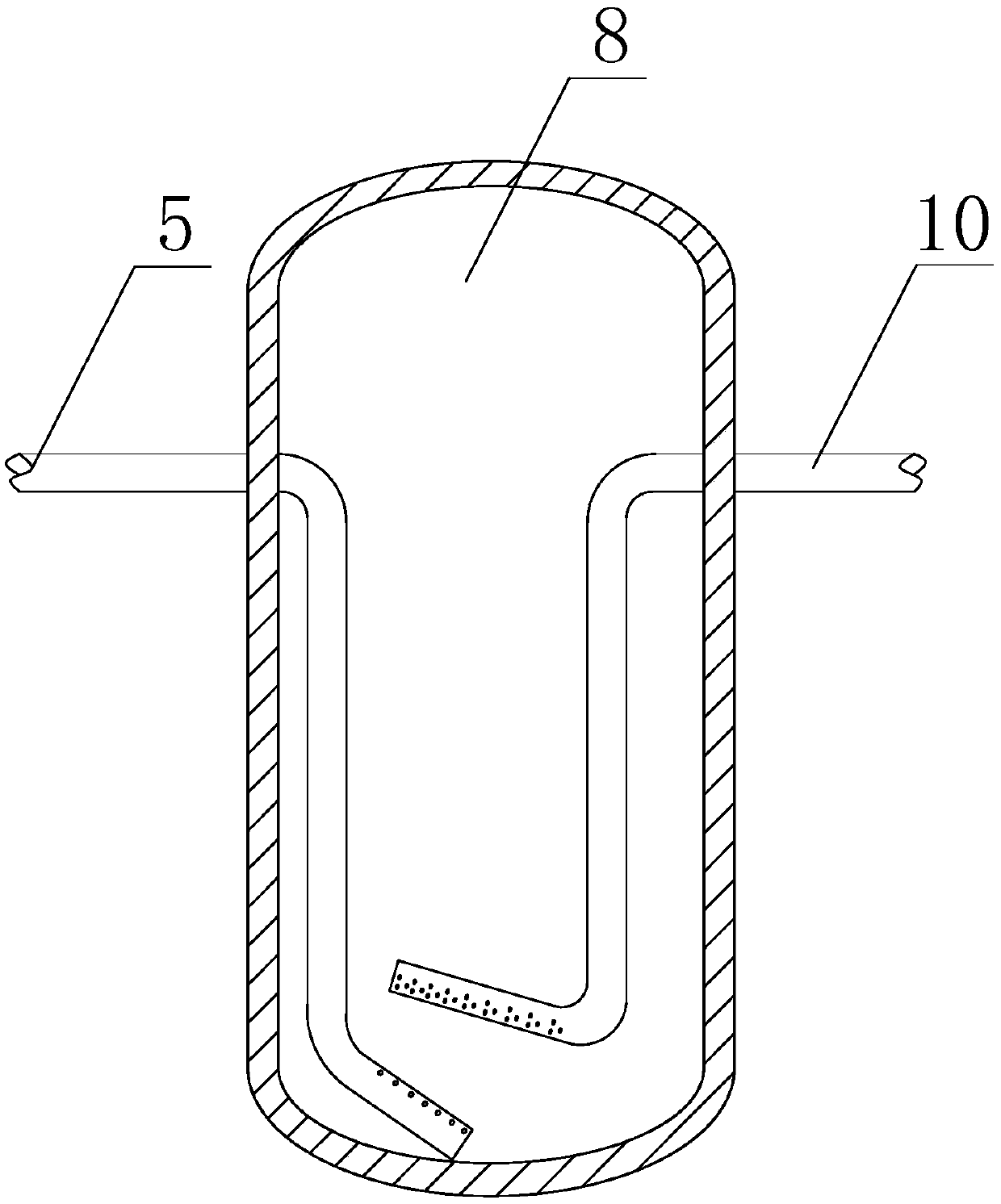

[0048] Such as Figure 1 to Figure 3 As shown, this embodiment is further limited on the basis of Embodiment 1: as the specific outlet form of the gas source pipe 10 and the inlet form of the output pipe 5, the uniform ends of the gas source pipe 10 and the output pipe 5 extend to the dry powder container 8 , and both the air source pipe 10 and the output pipe 5 extend to the pipe section in the dry powder container 8, which is a cantilever pipe section;

[0049] The outlet end of the gas source pipe 10 is located above the inlet end of the output pipe 5, and the outlet end of the gas source pipe 10 and the inlet end of the output pipe 5 are all located at the bottom of the dry powder container 8;

[0050] Both the outlet end of the gas source pipe 10 and the inlet end of the output pipe 5 are provided with a sealing plate;

[0051] The outlet pipe holes of the air source pipe 10 are a plurality of holes provided on the wall of the air source pipe 10 , and the inlet pipe hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com