Automatic steel pipe interior and exterior integrated grinding system

A driving system and steel pipe technology, applied in grinding machines, grinding workpiece supports, grinding driving devices, etc., can solve the problems of inapplicability, low safety and reliability, and low work efficiency, so as to meet production needs and improve grinding. High efficiency and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

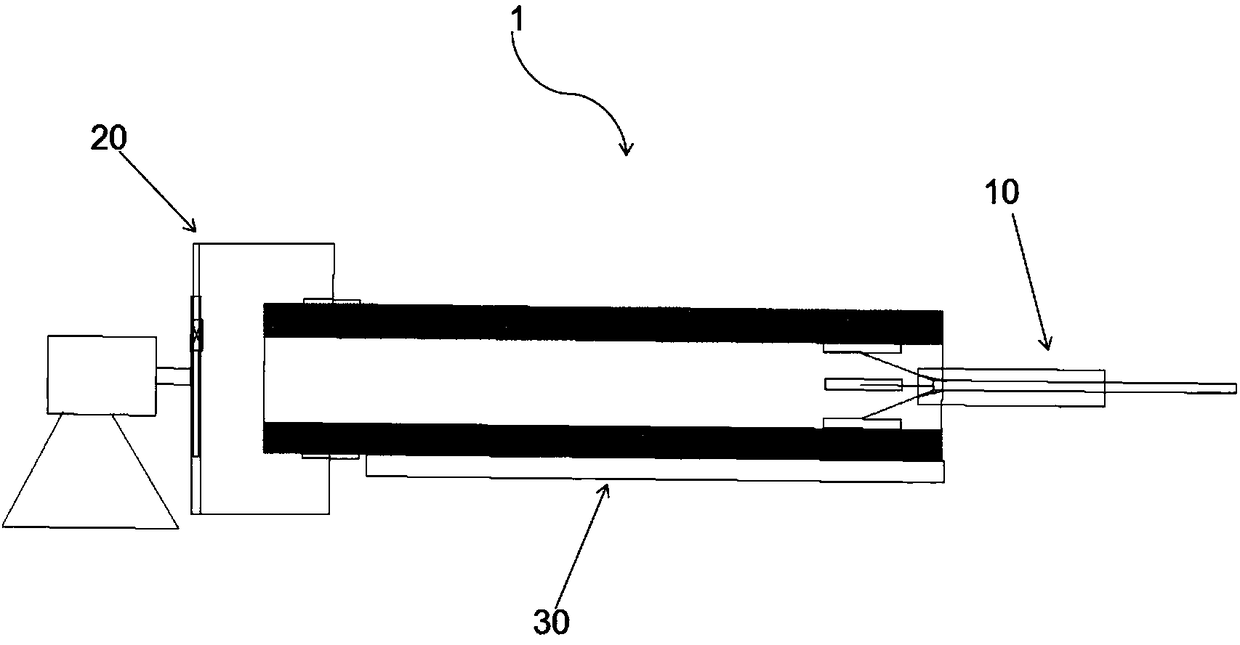

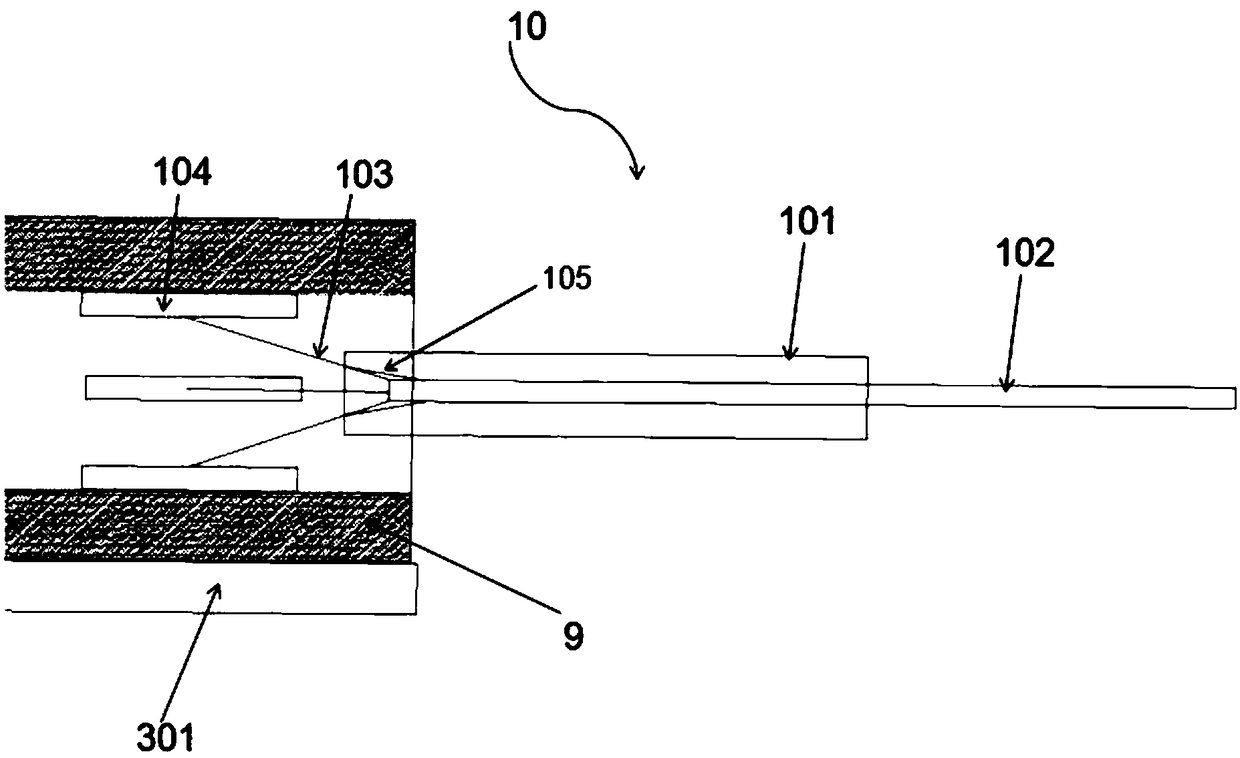

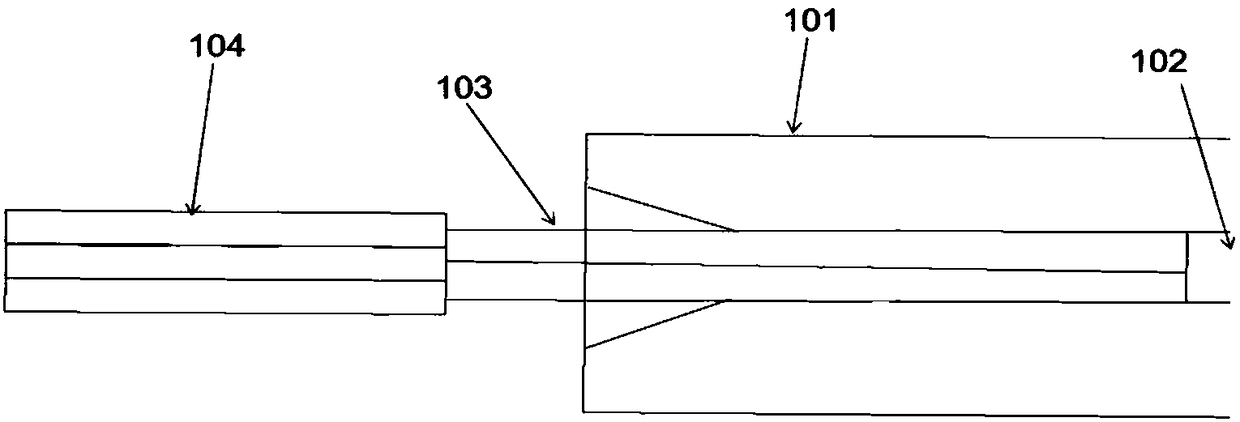

[0026] like figure 1 As shown, a steel pipe internal and external integrated automatic grinding system 1 includes an inner wall grinding device 10, a steel pipe fixing device 20, an outer wall grinding device 30 and a drive system. The steel pipe internal and external integrated automatic grinding system 1 can synchronize the inner wall and the outer wall of the steel pipe 9 Grinding and polishing. like figure 2 As shown, it is a schematic diagram of the structure of the inner wall grinding device 10 in an open state when it is working. The inner wall grinding device 10 includes an outer sleeve 101, an inner sleeve rod 102, and the inner sleeve rod 102 is inserted into the outer sleeve 101 and the two ends are separated from the outer sleeve 101 respectively. Extending from the center, the front end of the inner rod 102 is connected to the ends of a plurality of elastic branches 103, and each elastic branch 103 is provided with a grinding block 104 at the front end.

[0027...

Embodiment 2

[0034] A preferred embodiment of driving the inner wall grinding device 10 is provided. The integrated automatic grinding system for inside and outside of the steel pipe also includes a fixed column 50 on which a fixed bolt 501 is arranged. External thread engagement. The drive motor 402 of the inner wall grinding device drives the entire inner wall grinding device 10 to rotate clockwise, and at the same time makes the inner wall grinding device 10 move forward at a constant speed along the axial direction of the steel pipe relative to the fixing bolt 501, so as to realize the grinding of the inner wall of the entire steel pipe.

Embodiment 3

[0036] The front end of the outer sleeve 101 of the inner wall grinding device 10 in the first embodiment is provided with a V-shaped opening 105 for constraining and controlling the opening angles of the multiple elastic branches 103 . Since the processing technology of the V-shaped opening 105 is relatively complicated, there are also requirements for the wall thickness of the outer sleeve 101. In order to facilitate the production and popularization of the inner wall grinding device 10, alternatives, such as Figure 8 As shown, a V-shaped sleeve 106 is inserted into the front end of the outer sleeve 101 and fixed, instead of the V-shaped opening 105 in the first embodiment. Only the common outer sleeve combined with the V-shaped sleeve 106 is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com