Method for foam investment molding using automatic molding and cutting equipment

A technology of automatic forming and cutting equipment, applied in the field of investment casting, which can solve the problems of vertical transmission device collision, health hazards of processors, and failure to meet the high-precision requirements of investment molds, etc., to reduce resistance wire breakage, improve cutting efficiency, Guaranteed the effect of good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

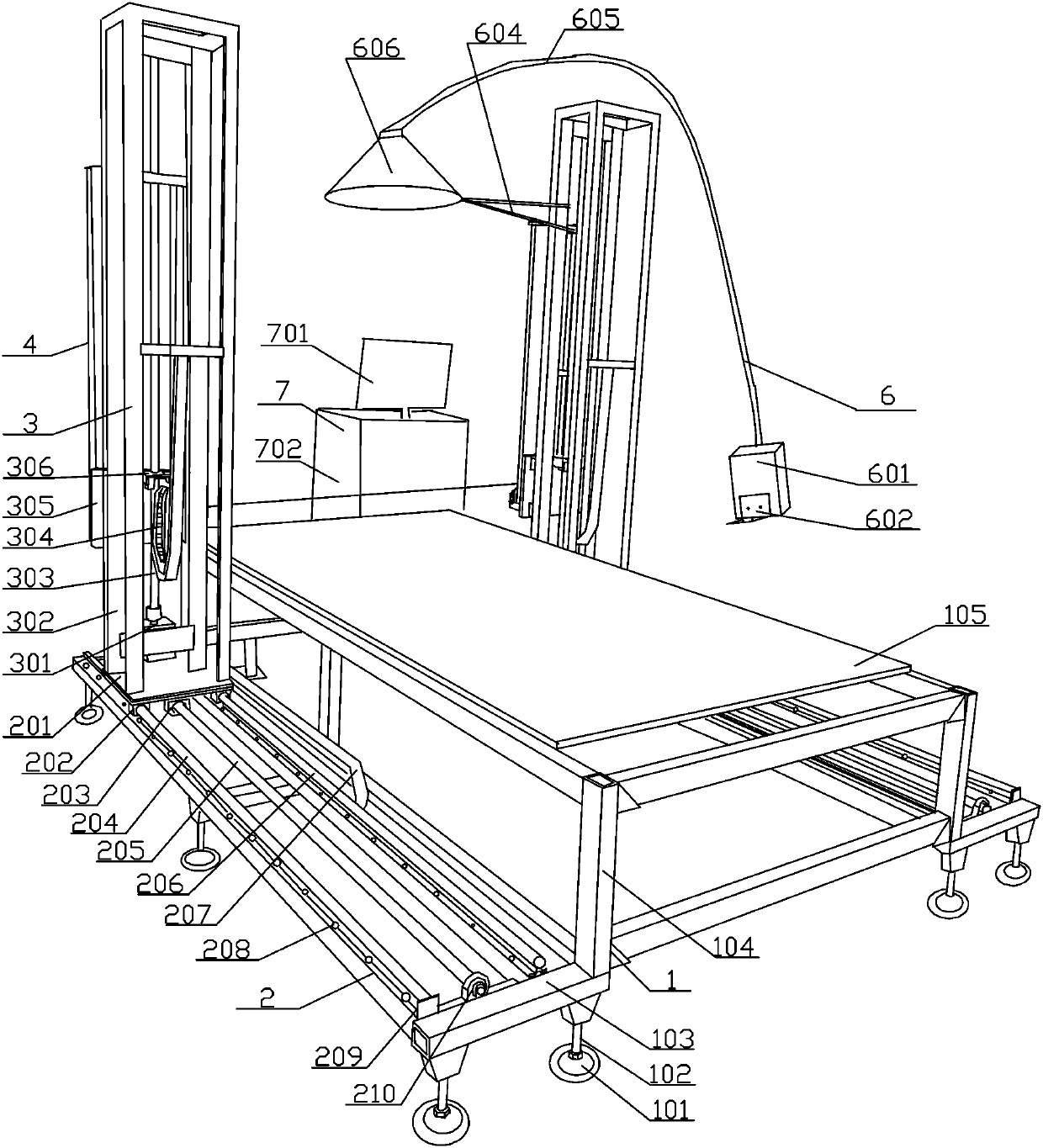

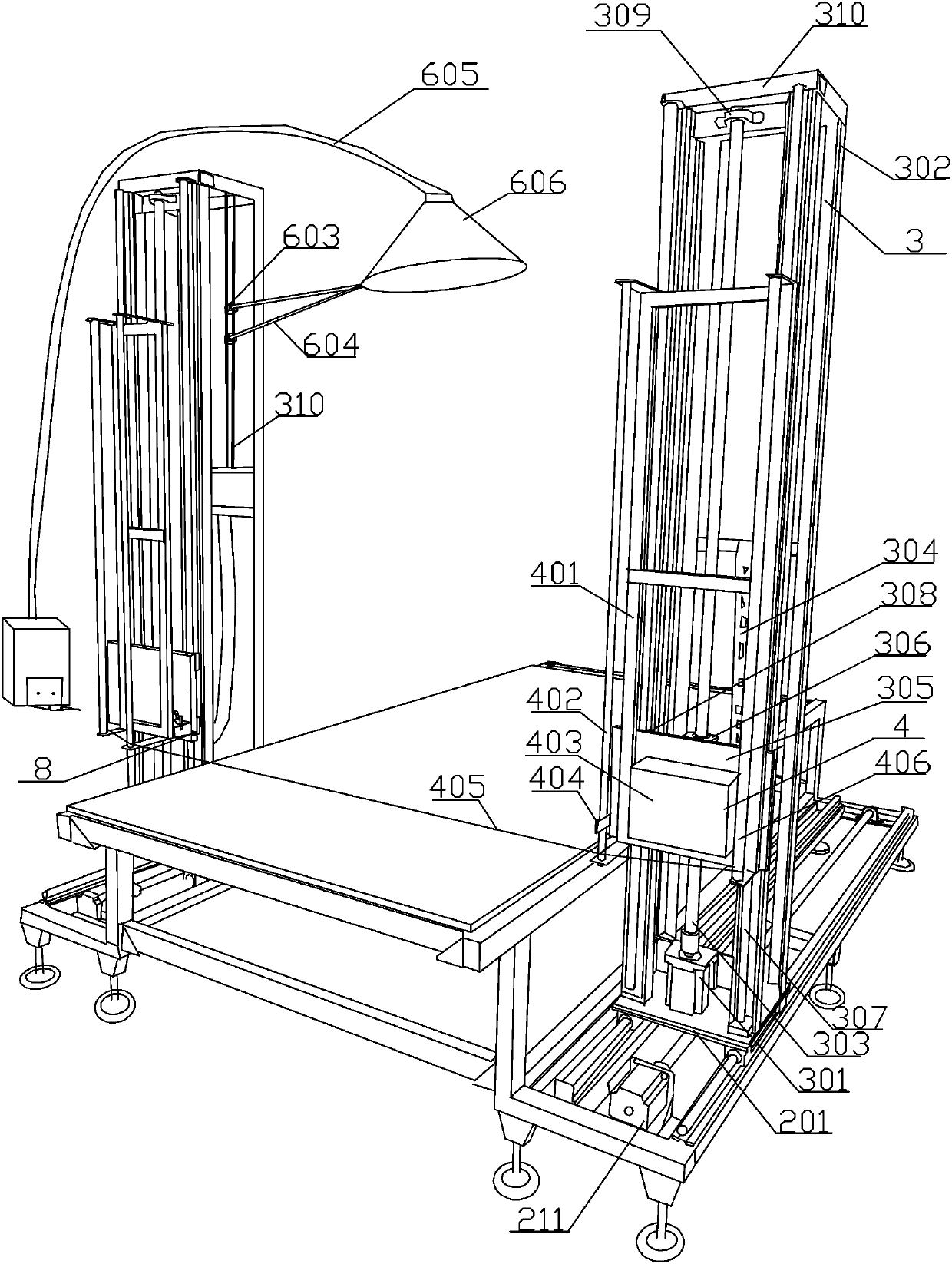

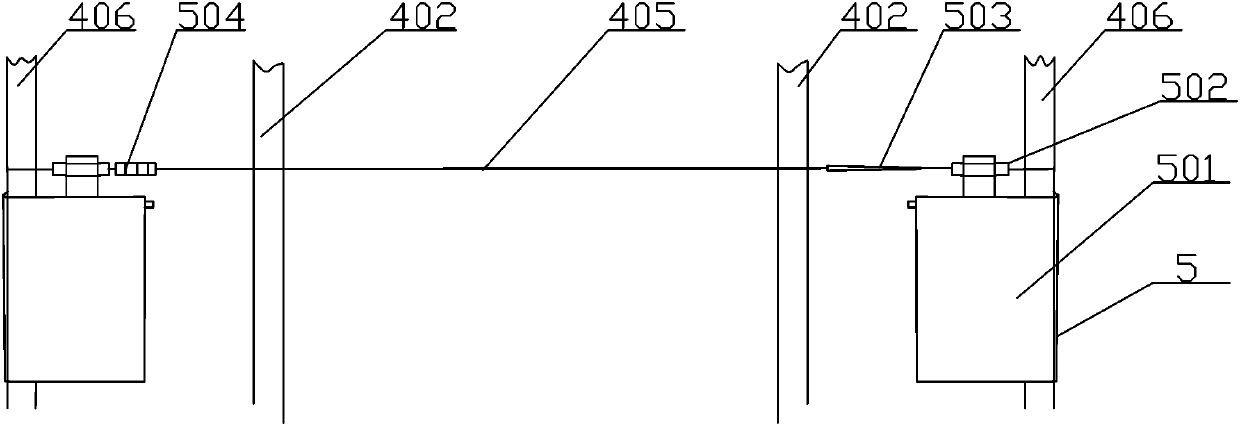

[0050] see Figure 1-6 , lost foam casting foam investment mold automatic molding and cutting equipment, which includes a frame device 1, the two sides of the frame device 1 are symmetrically installed with a transverse transmission device 2 for providing lateral movement, and the top of the transverse transmission device 2 is installed There is a vertical transmission device 3 for providing vertical movement, and a resistance wire cutting device 4 for cutting is installed on the vertical transmission device 3, and a tension regulator for controlling the tension force is installed on the resistance wire cutting device 4 Mechanism 5, a waste gas collection device 6 is installed on the vertical transmission device 3; the horizontal transmission device 2, the vertical transmission device 3, the resistance wire cutting device 4, the tension adjustment mechanism 5 and the waste gas collection device 6 are simultaneously connected with the control module 7 connected. By using the a...

Embodiment 2

[0060] The molding method of any one of the lost foam casting foam investment automatic molding cutting equipment, it comprises the following steps:

[0061] Step 1: Fix and place the foam investment mold on the workbench 105;

[0062] Step 2: Start the controller 701 according to the shape and structure of the investment mold to be cut, and control the horizontal transmission device 2, the vertical transmission device 3, the resistance wire cutting device 4, the tension adjustment mechanism 5 and the exhaust gas collection device 6 through the controller 701 start up;

[0063] Step 3: Drive the horizontal sliding plate 201 to move laterally through the horizontal transmission motor 211 of the horizontal transmission device 2, and then drive the resistance wire cutting device 4 to move horizontally, and drive the vertical sliding plate through the vertical transmission motor 301 of the vertical transmission device 3 305 moves vertically, and then drives the resistance wire cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com