A device for preparing ultrafine fiber nonwovens by using turbulent flow

A technology of ultra-fine fiber and non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles, papermaking, spinneret assemblies, etc., and can solve the problems of not effectively utilizing the drawing effect of polymer melts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

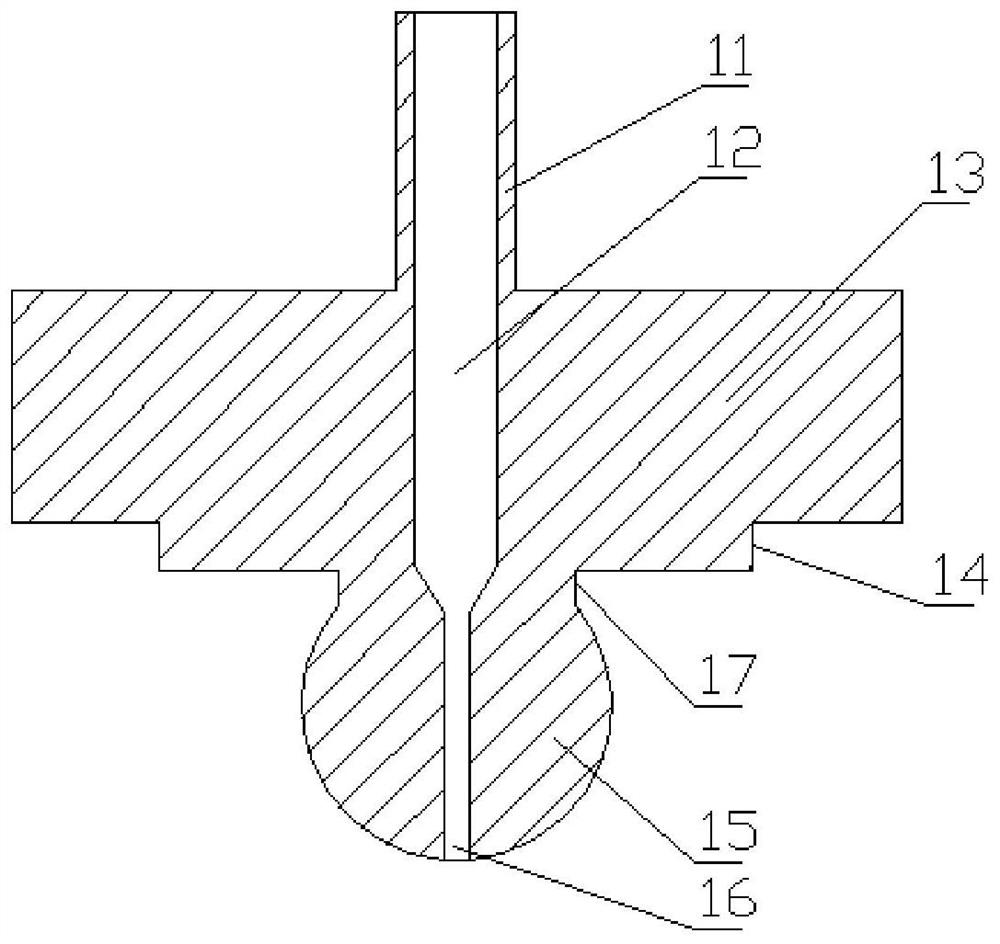

[0026] The present invention provides a device for preparing ultrafine fiber non-woven fabrics by using turbulent flow. The present invention will be described below in conjunction with the schematic structural diagrams of the accompanying drawings.

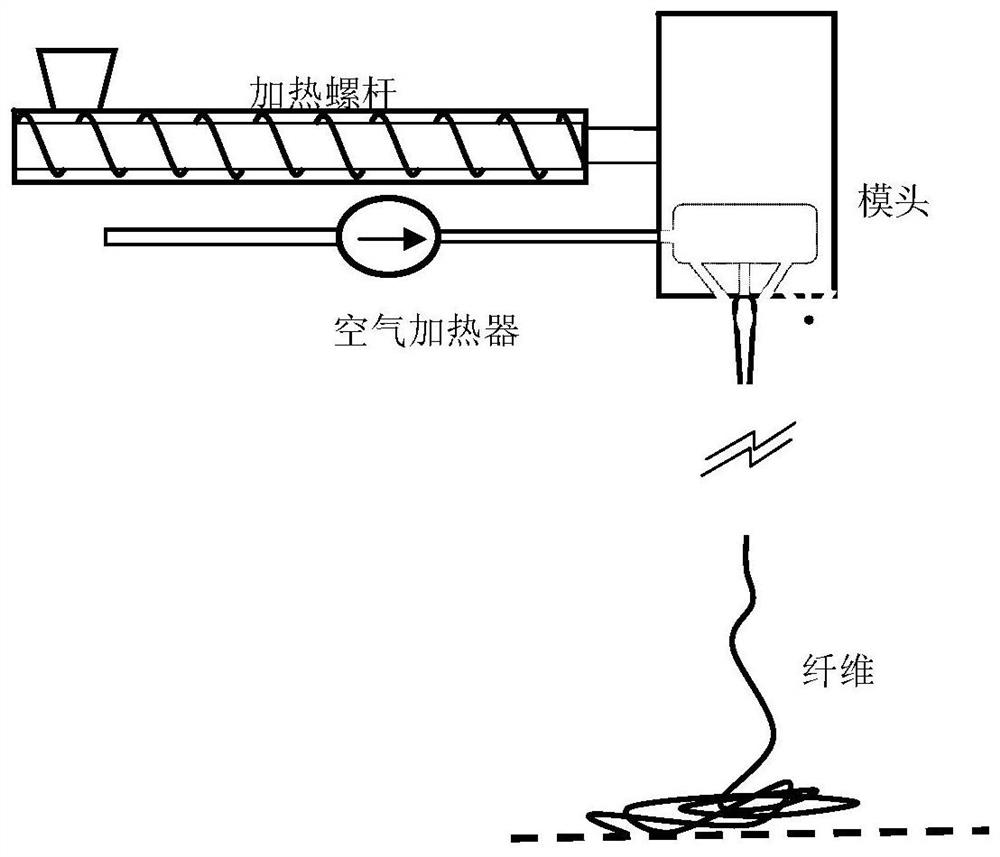

[0027] Such as Figure 1 to Figure 2 As shown, the present invention provides a device for preparing ultrafine fiber nonwoven fabrics using turbulent flow, including a hopper, the outlet of the hopper communicates with a heating screw, and the outlet of the heating screw communicates with a quantitative distribution device, and the quantitative distribution The device communicates with the die head, and the die head is connected with a quick-change joint, and the quick-change joint is connected to an air heater through a connecting pipe, and the air heater is communicated with a fan;

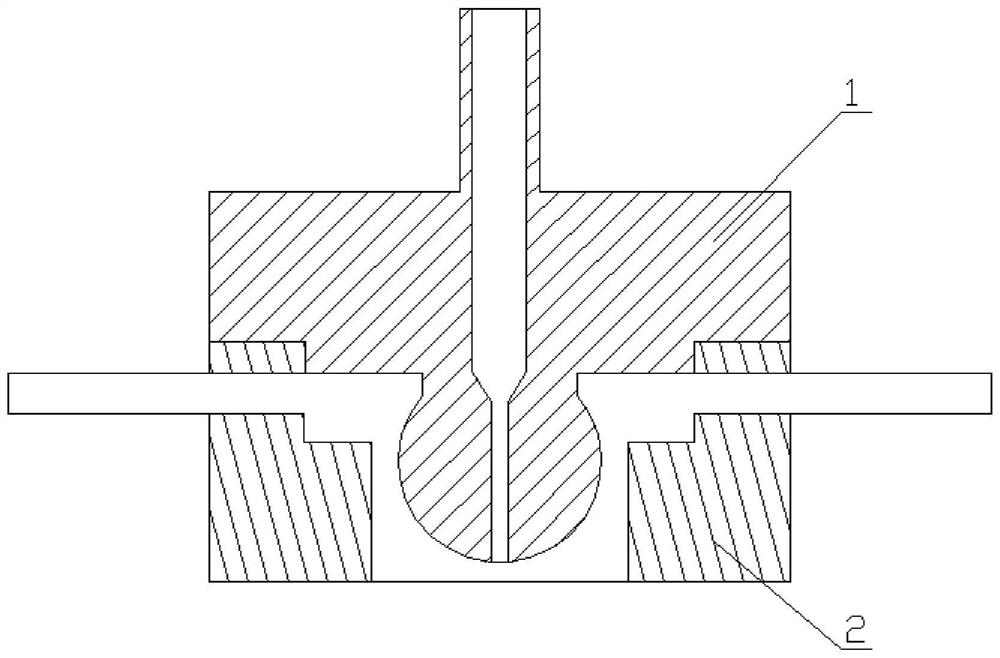

[0028] The die head includes an upper die 1, a cylindrical spoiler is arranged inside the upper die 1, a lower die 2 is arranged directly below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com