Continuous anti-pilling machine and anti-pilling production process

A shaker and shaker room technology, which is used in the filtration of dispersed particles, the separation of dispersed particles, and the removal of smoke and dust, can solve the problems of enlarging the distance and inconvenient operation of the staff, so as to increase the path, improve the kneading effect, and improve the requirements. come effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

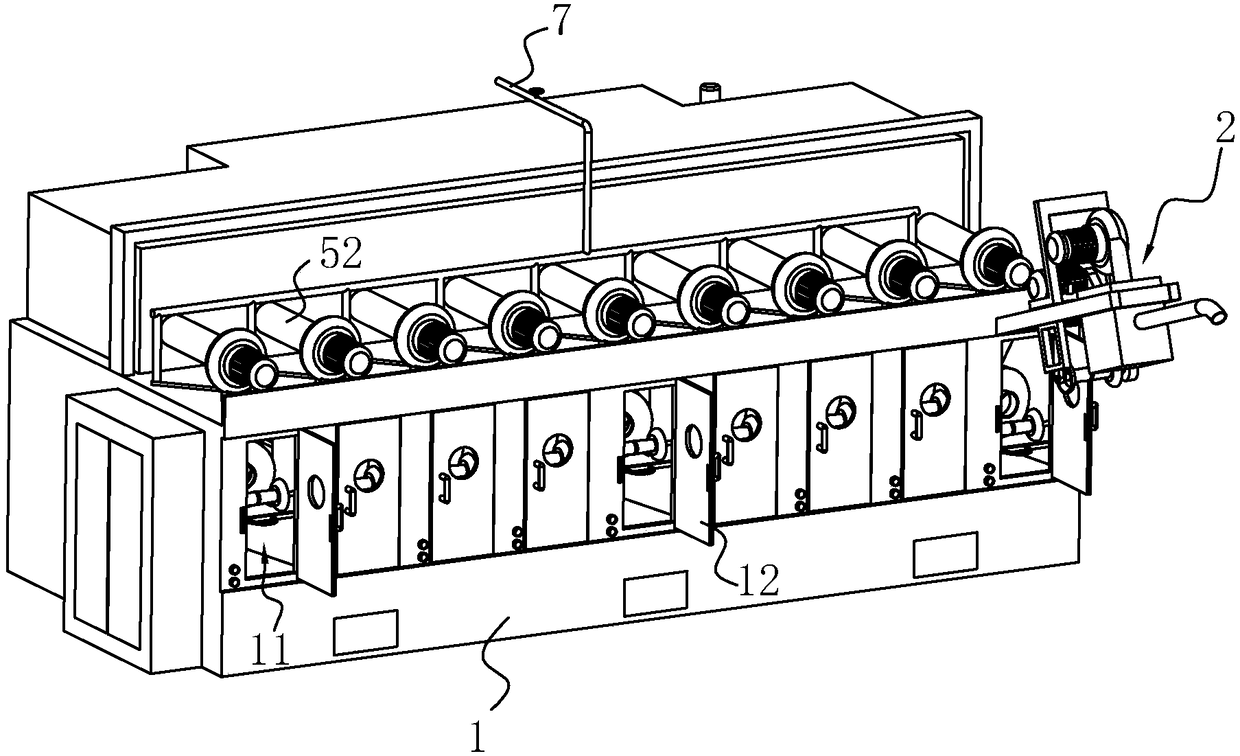

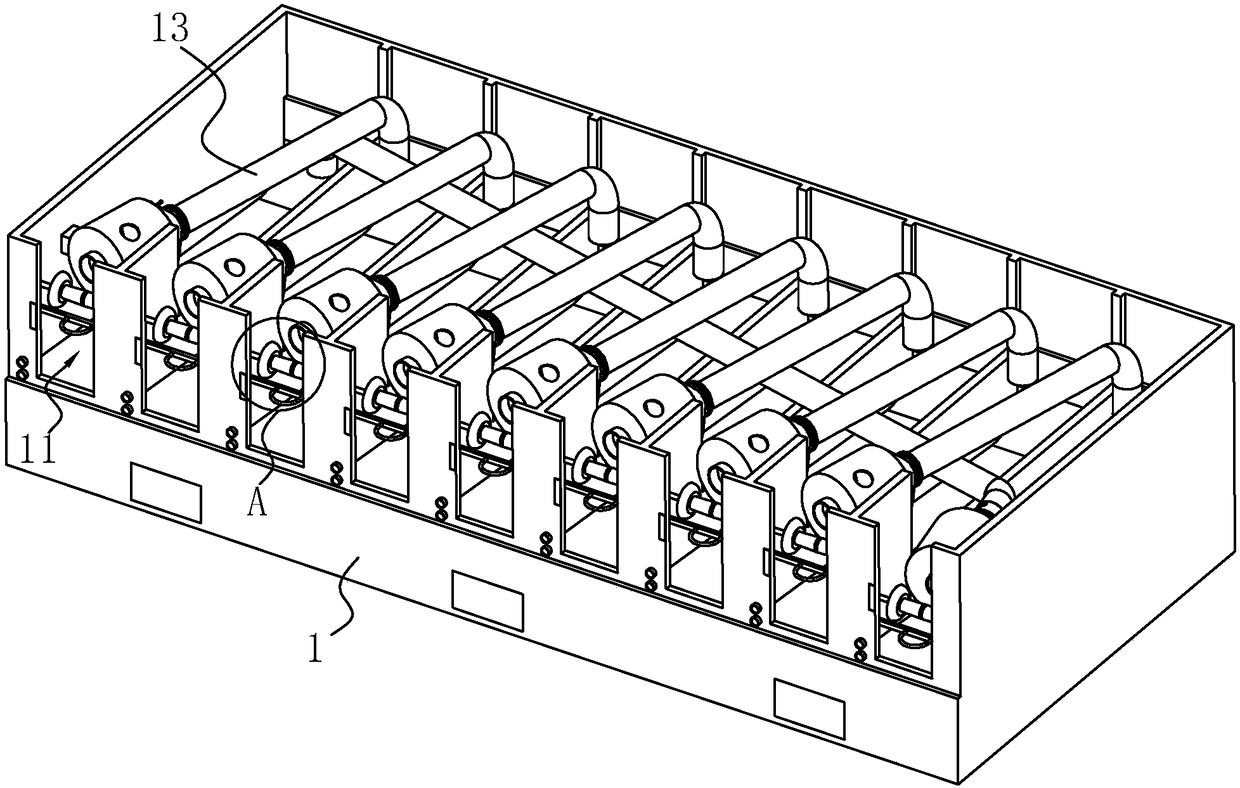

[0051] A continuous shaker, refer to figure 1 , including a case 1, in which there are N interconnected shaker chambers 11, and each shaker chamber 11 is correspondingly provided with an electromagnetic door 12, and the staff can send the fabric through the shaker chamber 11 after opening the electromagnetic door 12 middle. In addition, a cloth outlet device 2 is provided outside the Nth grain chamber 11, so as to facilitate sending the finished fabric out of the grain chamber 11.

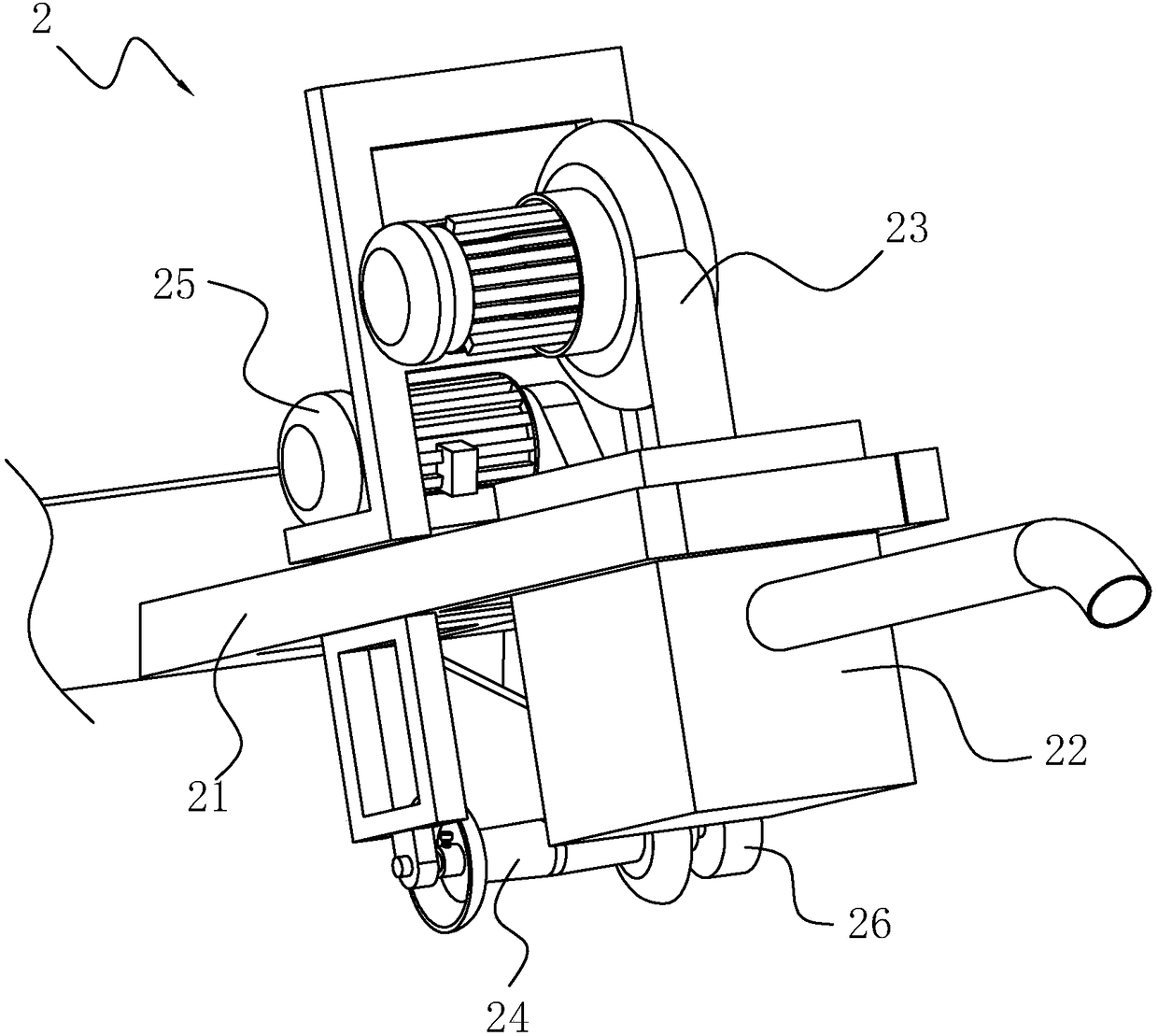

[0052] refer to figure 2 The cloth outlet device 2 includes a bracket 21 which is fixedly connected to the chassis 1 and is inclined upwardly. The lower surface of the bracket 21 is fixedly connected with a cloth outlet venturi tube 22. Out of cloth fan 23. A cloth outlet roller 24 is provided at the entrance of the cloth outlet venturi pipe 22 , and the cloth outlet roller 24 is rotatably connected to the bracket 21 . Moreover, the upper surface of the support 21 is also provided with a cloth...

Embodiment 2

[0063] A production process for eccentric pellets, based on the continuous eccentric pellet machine described in Embodiment 1, comprising the following steps:

[0064] S1: cloth feeding; all cloth lifting rollers 31 and cloth lifting fans 4 start to work, the heating device 51 does not work, and the staff feeds the fabric from the entrance of the first venturi tube 13 until the fabric passes through the Nth venturi tube 13 outlets are sent out, and then, the end of the fabric is tied, and the fabric will circulate in N Venturi tubes 13;

[0065] S2: Dust removal; all cloth lifting rollers 31 and cloth lifting fans 4 stop working, and after 10 seconds, the dust exhaust fan starts to discharge the dust and lint generated in the filter area 55 and the cloth feeding process to the collector through the action of the dust removal fan 62 inside bag 63;

[0066] S3: Shake particles; the dust exhaust fan stops working, and at the same time, the heating device 51 and the cloth lifting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap