Silent unit curtain wall

A unitized, curtain wall technology, applied in the direction of walls, sound insulation, buildings, etc., can solve problems such as the limit of sound insulation effect, achieve the effect of good noise reduction, increase reflection attenuation, and reduce noise penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

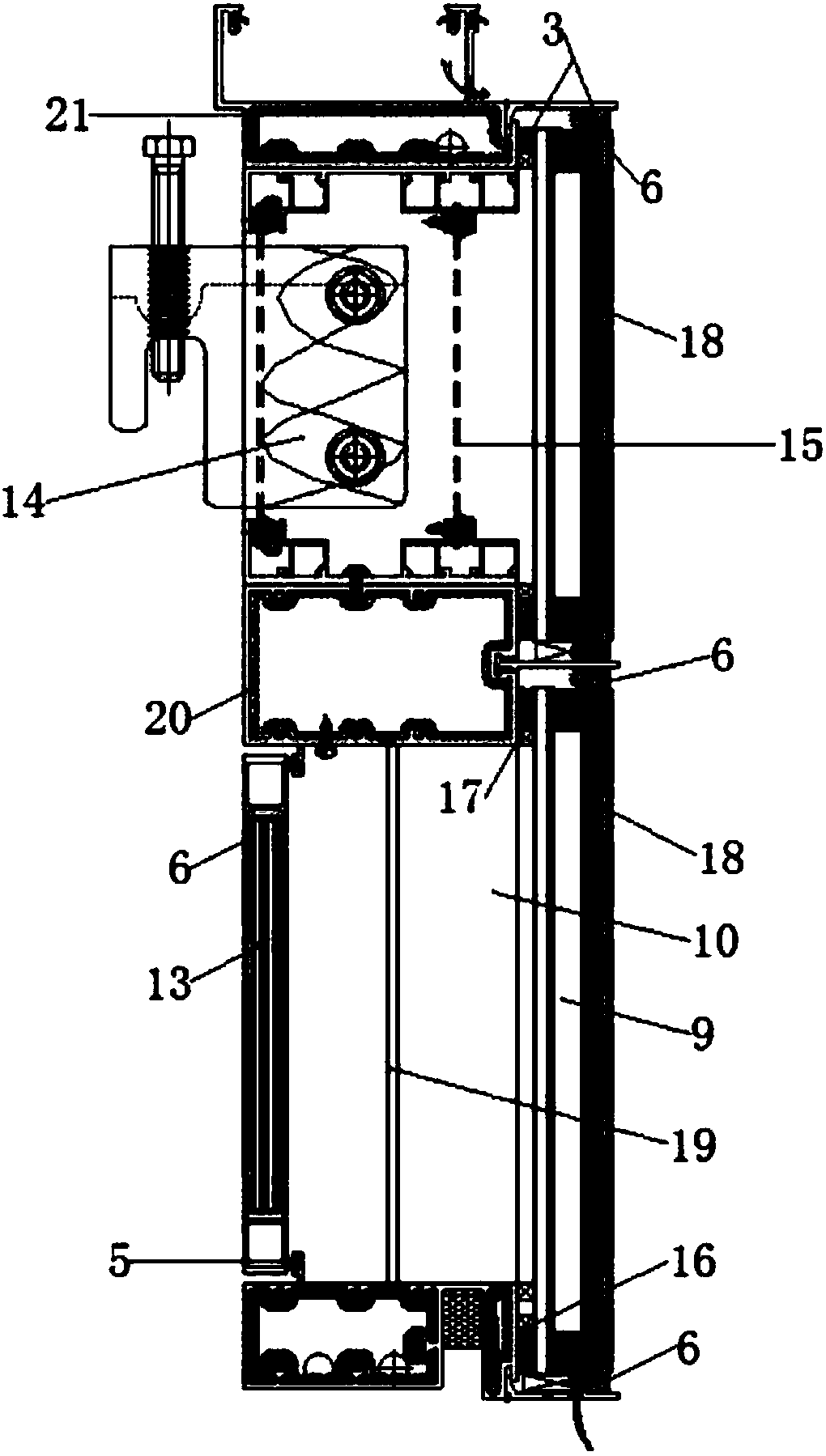

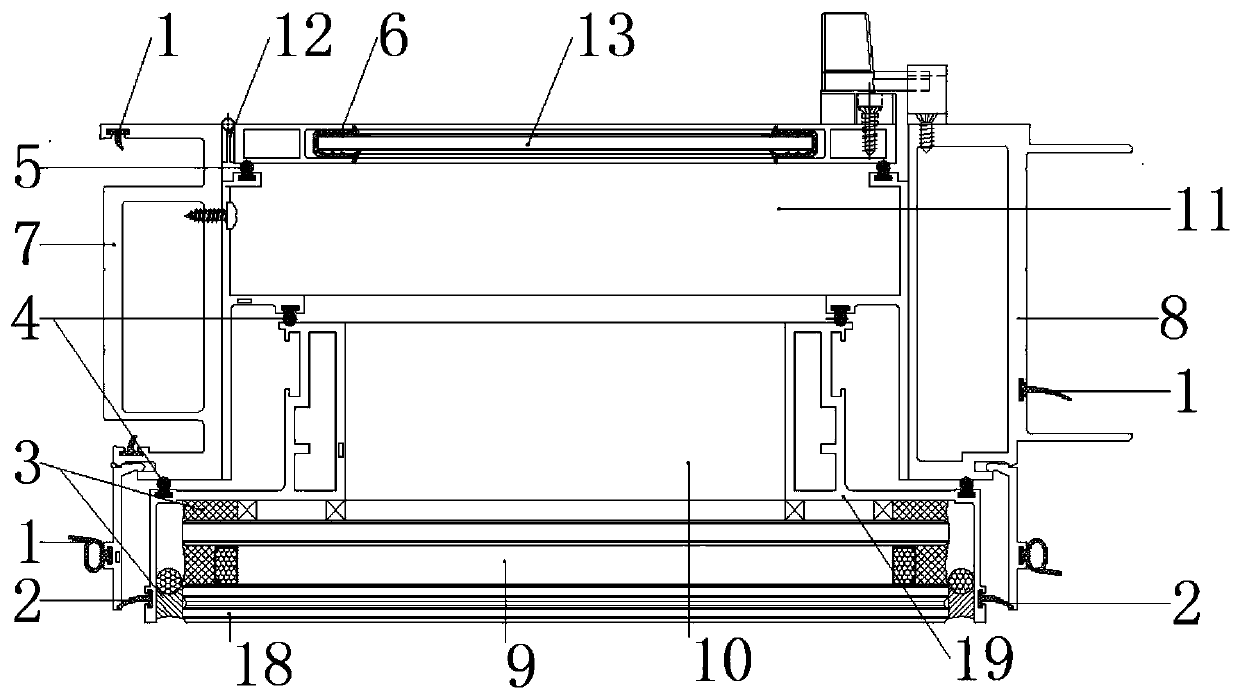

[0028] as attached figure 1 to attach Figure 6 Shown:

[0029] The present invention provides a silent unit type curtain wall, including the first inter-panel sealing strip 1, the second inter-panel sealing strip 2, silicone glue 3, the outer fan sound-absorbing strip 4, the inner fan sound-absorbing strip 5, and the inner fan sealant Bar 6, the aluminum alloy is connected to the left plate 7, the aluminum alloy is connected to the right plate 8, the first sealing chamber 9, the second sealing chamber 10, the third sealing chamber 11, the hinge 12, the first hollow laminated glass 13, Sound-absorbing cotton 14, galvanized sheet 15, double-sided sticker 16, structural glue 17, second hollow laminated glass 18, curtain wall panel 19, first curtain wall top panel 20, second curtain wall top panel 21 and foam rods Sealant 22; the left and right sides of the curtain wall panel 19 are bonded with an aluminum alloy connecting the left plate 7 and an aluminum alloy connecting the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com