Sunscreen knitted fabric and preparation method thereof

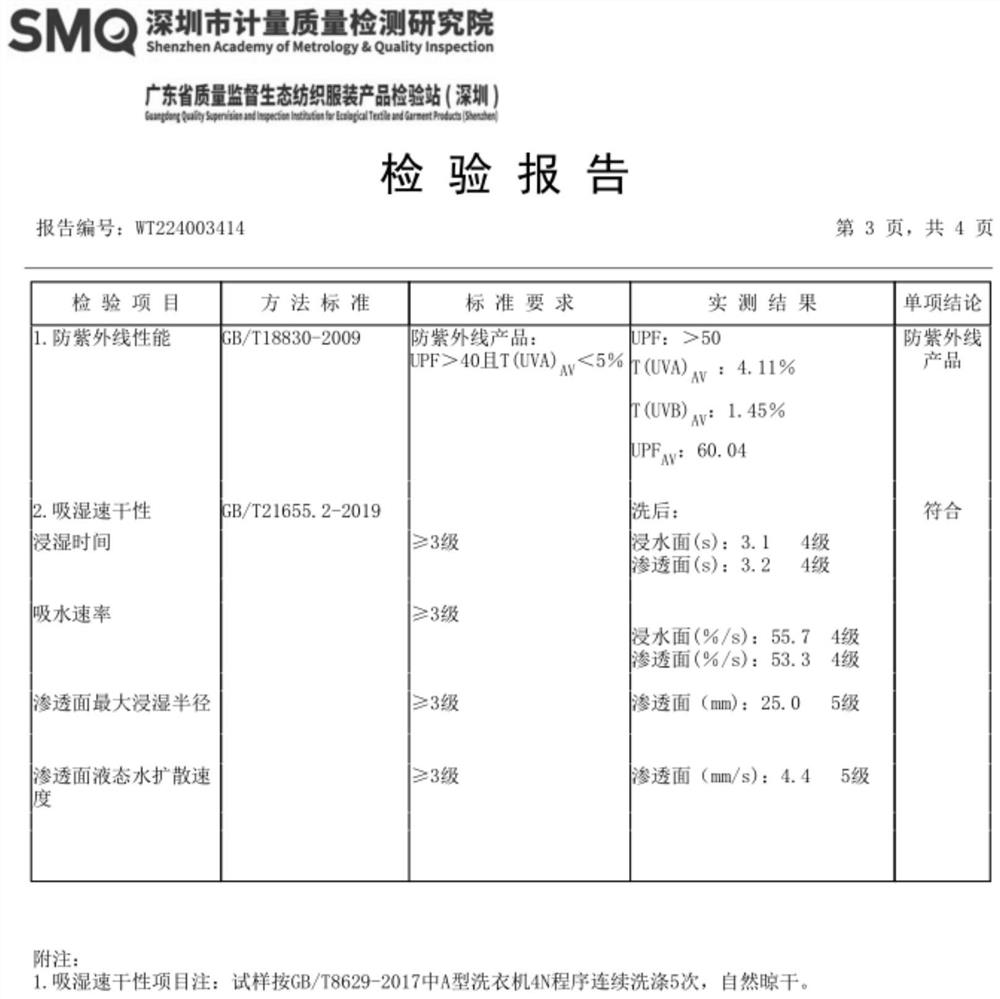

A knitted fabric and yarn technology, applied in the field of garment fabric processing, can solve the problems of reducing wearer's comfort, poor air permeability, comfort impact, etc., and achieve the effect of reducing direct sunlight penetration and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of the sunscreen knitted fabric described in any one of the above, comprising the following steps:

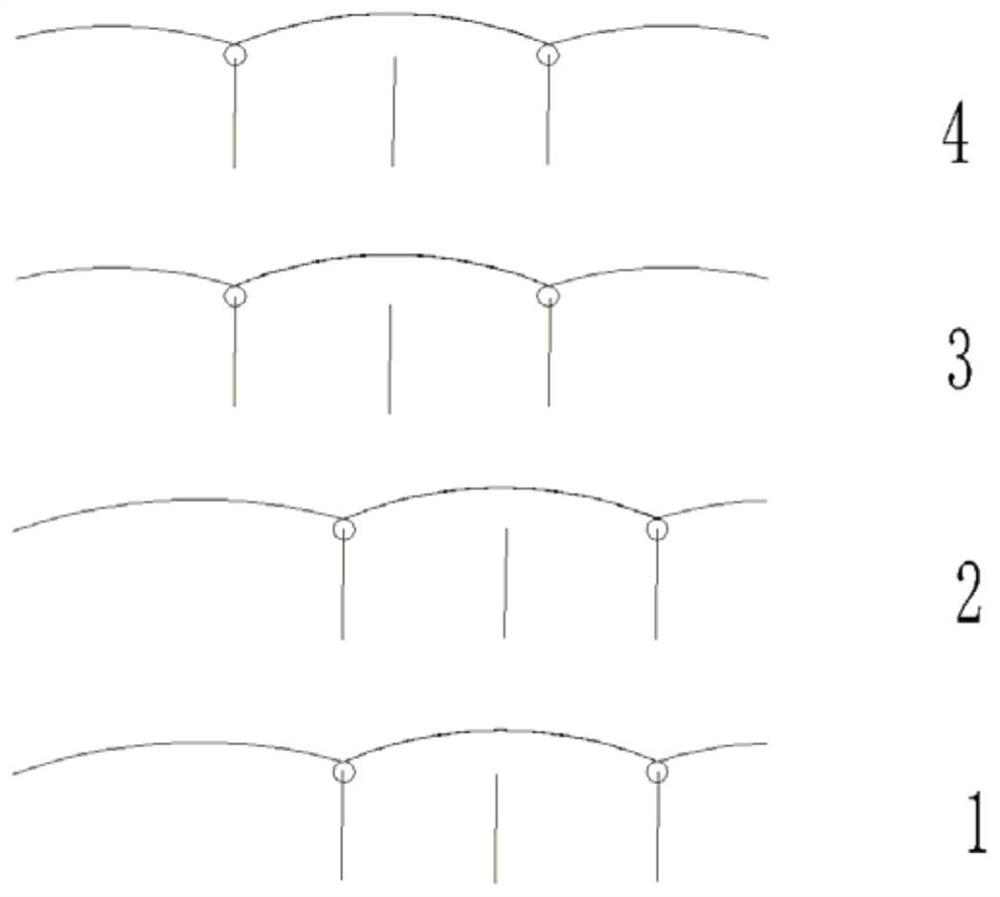

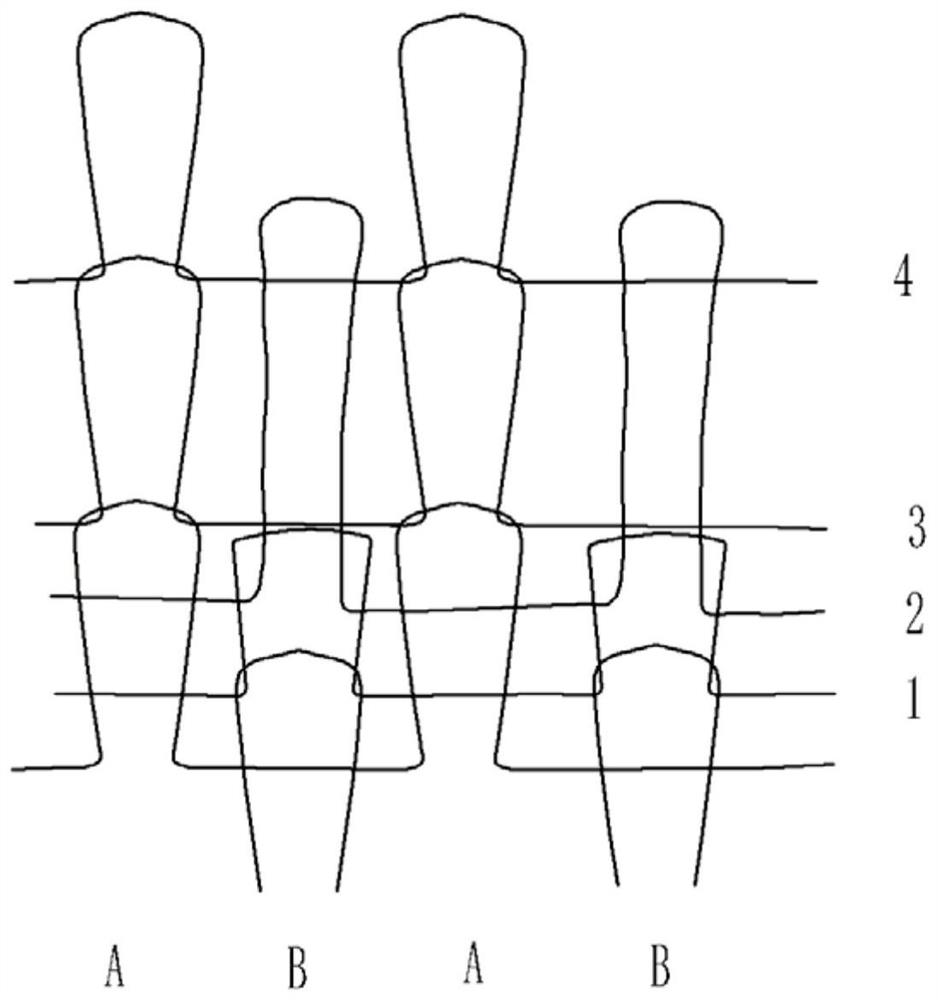

[0027] 1) Needle row: High and low needles are used to arrange needles at intervals, and the four routes are a cycle, namely ABAB; the first and second routes B needles are knitted into a circle, and the A needles are woven into floating lines; the third and fourth routes are woven into a circle. Needle B knits the floating thread, needle A knits into a circle;

[0028] 2) Threading and weaving: the first and third threads are threading thread 1, the second and fourth threading thread 2, and weaving is performed after thread threading is completed.

[0029] In the present invention, two kinds of needles of high leg and low leg are used to arrange the needles at intervals, and the four paths are one cycle, namely ABAB (where the high leg is marked as A, and the low leg is marked as B); wherein the first and second p...

Embodiment 1

[0042] Raw material selection

[0043] Yarn 1: 60S cotton / modal blended yarn (50% cotton and 50% modal by weight); Yarn 2: 50D / 32F stretch polyester fiber.

[0044] weaving

[0045] Weaving with high-density needle single-side weft-knitting circular knitting machine: 36G-40G single-side weft-knitting circular knitting machine

[0046] 1) The pin headers are high-pin and low-pin spaced pin headers: ABAB…,

[0047] 2) There are four routes in a row triangle, one process cycle, the 1st and 2nd routes B needles are knitted into a circle, and the A needles are woven into a floating thread; the 3rd and 4th routes B needles are woven into a floating thread, and the A needles are woven into a circle.

[0048] 3) Threading and weaving: the first and third threads are threading the yarn 1, the second and the fourth threading the thread 2, and the order cannot be reversed.

Embodiment 2

[0050] The difference from Example 1 is that the content of cotton and modal in the cotton / modal blended yarn is different, 30% cotton and 70% modal, and the specific method is as follows:

[0051] Raw material selection

[0052] Yarn 1: 60S cotton / modal blended yarn (in which, by weight percentage, cotton 30%, modal 70%); yarn 2: 50D / 32F stretch polyester fiber.

[0053] weaving

[0054] Weaving with high-density needle single-side weft-knitting circular knitting machine: 36G-40G single-side weft-knitting circular knitting machine

[0055] 1) The pin headers are high-pin and low-pin spaced pin headers: ABAB…,

[0056] 2) There are four routes in a row triangle, one process cycle, the 1st and 2nd routes B needles are knitted into a circle, and the A needles are woven into a floating thread; the 3rd and 4th routes B needles are woven into a floating thread, and the A needles are woven into a circle.

[0057] 3) Threading and weaving: the first and third threads are threading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com